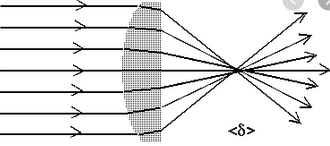

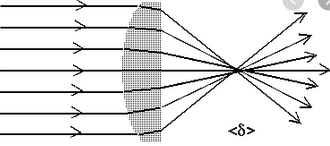

Check the orientation of the lens and be sure the outward curved side (convex) is facing up.

1 Like

Check the orientation of the lens and be sure the outward curved side (convex) is facing up.