Are you moving the head with the arrow keys in lightburn or moving it by hand? If you move it by hand, the machine and lightburn don’t know where they are. If you are using user origin or absolute coordinates, only move the laser with software.

I moved it with the arrows. Distance was set to 10cm so 4 clicks to each sides.

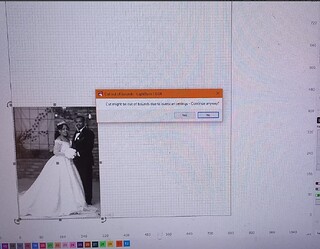

It lookls like the preview doesn’t finish either. Upload the file for me to take a look at.

I took the screenshot midway that’s why. But please do. I’m starting to think it’s something with the image or file. Because it cuts and engraves vector to completion before. I will try another job tomorrow to check.

Wedding.lbrn2 (816.5 KB)

I don’t see any issues with the file.

Try this. Turn the laser off and unplug power and the USB cable for 30 seconds then reconnect. Move the laser head to the front left corner of the laser before turning it on, then turn it on. Go to the move window and click get position to verify it’s at 0,0. Set Lightburn to absolute coordinates. Make sure the image is at least 20mm from all edges. Run the file. If it gives the out of bounds error, don’t bother running it.

If it errors, type $$ then enter key in the console. Copy/paste the output here.

Starting stream

Layer C00

[MSG:Restoring spindle]

[MSG:Restoring spindle]

ALARM:3

Reset while in motion. Grbl cannot guarantee position. Lost steps are likely. Re-homing is highly recommended.

On or near line 0:

Job halted

Stream completed in 13:21

Grbl 1.1f [‘$’ for help]

[MSG:‘$H’|‘$X’ to unlock]

[MSG:Caution: Unlocked]

ok

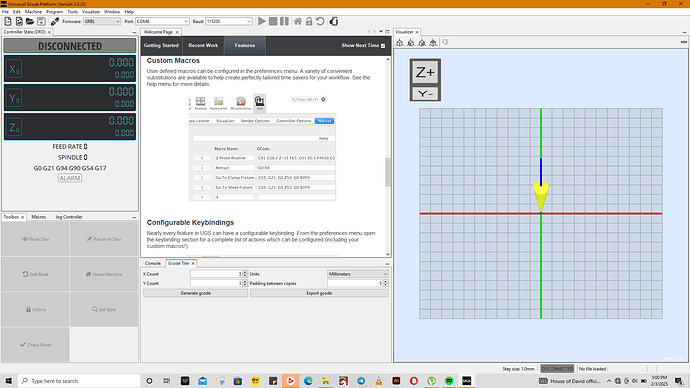

$$

$0=10

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=0

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=0

$23=0

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=1

$33=1

$34=1

$35=0

$36=1

$37=1

$38=10

$39=0

$100=80.000

$101=80.000

$102=80.000

$110=20000.000

$111=20000.000

$112=20000.000

$120=500.000

$121=500.000

$122=500.000

$130=1500.000

$131=1500.000

$132=300.000

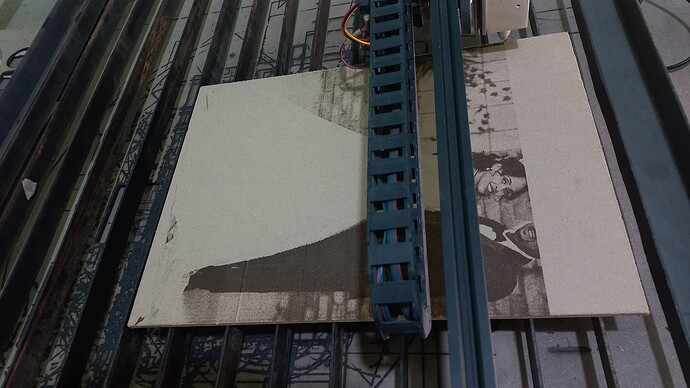

First it went without interruption for almost 4 hours even though it said less than that in the preview and Alarm 3 was triggered.

The above is when I tried to run it again from the preview with the ‘start from here button’

The image was almost completed before the error came on.

The

I’m not sure why I didn’t make this connection earlier. Alarm 3 is typically a data error / connection issue. Since it happens randomly, not at the same file location, it’s likely a bad USB cable or connection. Try a different, higher quality USB cable.

I bought the machine only a year ago and my doubt is this has happened about 4 to 5 months after I bought it and the people that sold it to me sent a universal g-code sender because I didn’t know how to home it then and it has worked just fine since.

I live in another city from where I bought it and it will be a while to get that but I will try to get a new one here. Is there a kind you recommend? What should I ask for?

I don’t know what that is or how it’s suppose to work, but it could be a communication issue between it and the controller???

Get one with the ferrite core on the ends, that eliminates a lot of issue. You also want one that is somewhat thick, those usually have better shielding of the cable.

So this is a software between Lgithburn and the laser? Are you connected to this with Lightburn, then to your laser, or are you saving from Lightburn as a gcode file then opening that in UGS?

No I just use it to soft reset whenever my machine acts up. I connect it to the machine and follow the steps reset zero and disconnect. Then I open lightburn and continue to work.

That’s a workflow I’m totally unfamiliar with. You should be able to do that from Lightburn, I think.

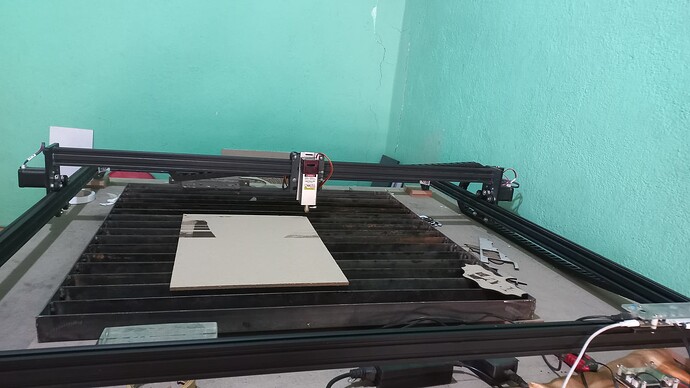

What is the size of your machine?

Any particular reason you have your machine defined in Lightburn with a Width = 800 Eight > 800?

And your machine GRBL have 1500 x 1500? Correct that first please.

.

A bit of info on GRBL settings:

https://github-wiki-see.page/m/gnea/grbl/wiki/Grbl-v1.1-Configuration

Yes it’s no longer working either. Other than changing the cable is there anything I need to check or do?

And also, I know my machine is supposed to cut a 3mm MDF with 3 to 4 passes but it only cuts after 10 to 12 passes. Sometimes I’ll have to run it again the thing is the laser head needed a driver adapter they told me the control board couldn’t pass enough power and now I use it with additional 24V adapter.

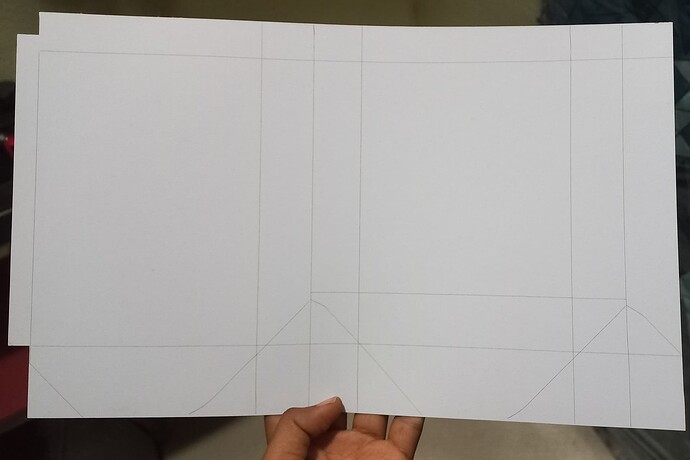

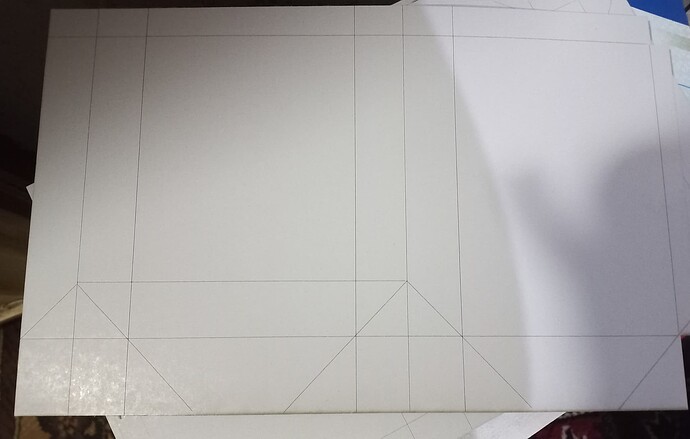

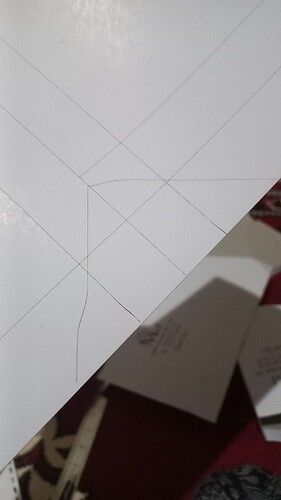

Do you recognize my machine from the photos I had sent previously and tell if anything is missing? I am thinking about disassembling it and replacing it. But I wanted to know what I was doing and what needed to be done first.

No, I don’t recognize your machine, but that’s not unusual. There are a LOT of different lasers out there. Start with a new cable, then let’s see if we can get your machine talking to Lightburn and skip the UGS.

I found out that my laser head was functioning as a 40watt even though it was 80watt and there’s no solution so we bought laser tree k30 diode an 4-axis 24v control board.

We also changed the USB cable with a new one and I am yet to try finishing an image Engraving job to see if the Alarm 3 persists, but I’m afraid there still is a problem because when I tried to run a line file it completes it cleanly half the time and messes it the other half times.

It creates a straight line one time and it makes it curved and zigzag the next time the same file runs. It also shifts the horizontal lines upward