I do a crap ton of these patches a month, and it’s a pain to clean each and ever one. I’m running at 450mms 17% power, but they are still nasty after a run. Do I need more air or what.

You need less air. And I’d hazard to guess less power or more speed. Is that real leather?

No it’s laserable leather from JDS I believe. I don’t know that going over 450mms will really help any. If I go to low on power I lose detail.

I’m not sure how paper masking would hold on leather. I use on plywood high tack transfer tape from US Cutter. It sticks well and removes cleanly, sometimes curling on the close-together cuts/fills, but generally does a good job.

For acrylic and in this case, possibly leather, consider to mix up a bit of water and dish detergent. It will take some experimenting, but aim for a high ratio on the soap end. Apply it to the leather. You can either let it dry or work it while wet. For the former, once you’ve engraved it, the dried soap will wash away. You’d have to wash the soap application, wet or dry.

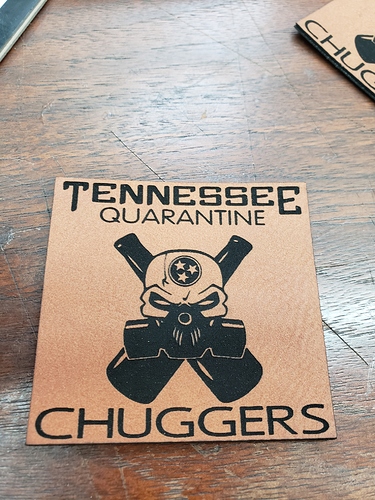

This stuff isn’t real leather. If it get to wet it curls up. @travisr100 changed my life by telling me I had to much air. So I cut it off and this is what finished product looks like. No wiping needed.

Air can be your enemy on engravings depending on the material. Assuming you have the standard aquarium pump for air, put a valve on there so you can get it so that there is just BARELY any air coming out of the nozzle. You just want enough air to keep the smoke from getting up to the lens.

Yea I’m still running the aquarium pump.

Transfer tape + minimal air (just enough to keep positive pressure in the nozzle to protect the lens from soot).

This is also a scenario where, with the proper cone adapter (you’d need a cone with a wider opening to clear the beam), you could use a 101mm lens in the lower position to reduce collision of air on the material while maintaining positive air pressure in the lens holder.

You would have to account for needing to focus at a new distance if you did this. There would be about 4” from the cone to the material.