My camera has been off for a few months now so we decided to go through the calibration process again. We followed the video on the camera calibration. Everything went well with capturing the dots and then we got to the section where you have to engrave the four corners and select the middle of the dots. We flipped the cardboard over that we had the dots affixed to so it was only a 8.5x11 size and put in 100 for scale. I’m not sure if this is where the problem was or not. What size should we be using in order to this part of the calibration? Should it be the same size as the bed? After we thought we had the calibration done, we ran some test lines on scrap wood to see how close we were to the edge of the piece and while it was close on the bottom when we put a line on the right side of the wood, it was way off. We have a Boss LS1630 laser.

By how much was it off?

Ideally this would be as large as can fit in the bed. This will help reduce the effect of any error in the process.

Some other things to look out for:

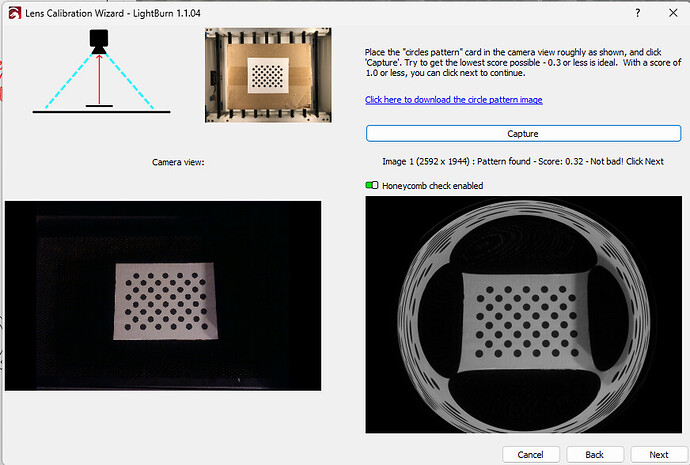

- After you did your lens calibration are images that are captured properly corrected for any lens distortion? All lines should appear straight, not bent. What types of scores did you get in the process?

- Did you focus the lens where it was as sharp as possible when the bed is at the proper focus distance to the laser lens? This should be done prior to camera alignment.

- When you created and captured the alignment targets, was the laser focus distance set appropriately for the material? The alignment is really only good at a single focus distance so that needs to be set accordingly.

- After you did your lens calibration are images that are captured properly corrected for any lens distortion? All lines should appear straight, not bent. What types of scores did you get in the process? Scores were between .25 and .43

- Did you focus the lens where it was as sharp as possible when the bed is at the proper focus distance to the laser lens? This should be done prior to camera alignment. Yes, I can’t remember if we did this before or after.

- When you created and captured the alignment targets, was the laser focus distance set appropriately for the material? The alignment is really only good at a single focus distance so that needs to be set accordingly. Yes, this was in focus to the material we were using

I went back to recalibrate today double checking that the camera lens was focused AND the laser focus distance was set. Now when I go to recalibrate this is what I am seeing:

A few seconds prior I had a clear image that was in focus – it is hit or miss if it works. I had a clear focused shot and started the calibration and during image capture 3 it was not finding any image even though it was in the exact spot it was supposed to be … I even moved the dots farther to the left and right than it should be and it wasn’t picking anything up so I figured it was my camera being wonky again.

Don’t concern yourself with the actual image and focus only on the score. Try to get at least “Great” scores on every position. You can do the lens calibration with the camera outside of the machine if that makes it easier. I suspect this will be a pain if it’s already mounted.

The lens calibration can be very finnicky with scores shifting at very small adjustments in position and light. You may want to get an external light source that you can move around to see how that affects the score. This could take dozens of captures to get right.

If you can’t get lens calibration to all Greats then try proceeding to alignment. Again, make sure that focus distance is correct with burn and subsequent capture. Burn as large a scale as reasonably possible.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.