There is no way to do to glass what you do to stainless with your fiber… or any laser. It’s just the way that material is.

Besides something like LBT100 or CerMark the only thing you can do with glass is shatter it. It doesn’t take well to one area being very much hotter than something right next to it…

Same thing happens to the dpssl lasers when they use tempera or some other type of coating that get excited (hot) by the beam. The heat in the coating shatters the glass… you can always feel them.

I run steel wool over glass mugs to ensure none of the glass shards end up in someones finger…

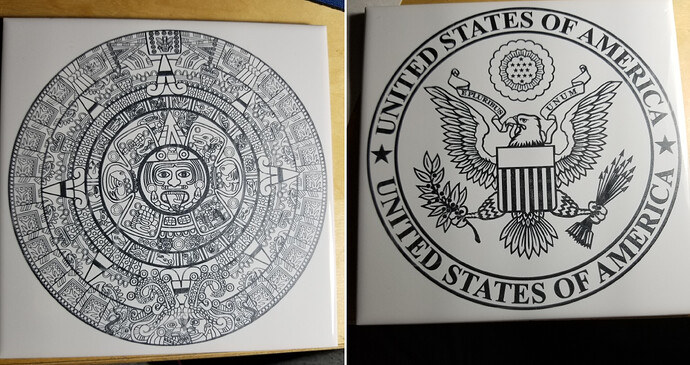

This is done on the fiber using TiO2 and water… it’s a 6"x6" porcelain tile, it’s glass… should work on a shot glass… These were not coated well, you can see the black density fading from left to right. Although you can feel these coating, they are much like the feeling of something silk screened with ink.

I’d suggest you try use a few of these coatings to do this… Find which one works the best for you.

LBT100 has a starting place in their documentation… I do know the more thin and even the coat the more resolution you get…

If you have some of this stuff, you should try it… It takes a bit of patience to get this to work properly… same ol, same ol…

Speed up and power down…

There is the NWT method using paint… this is some of @Bulldog tiles… His work is pretty incredible. Should work equally as well on shot glasses…

Good luck

![]()