Hey Bob,

I wasn’t able to be around here much for the last couple of days so I’m only just now being able to get back to you. So last things first:

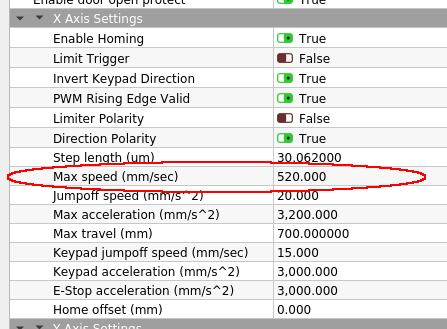

Yes, absolutely! The “Step length (um)” tells the controller how long one step (aka one pulse from the controller to the driver) would move the laser head and therefore how much pulses it has to send to the stepper driver to get your laser head move the requested distance correctly.

So has @Hank has already nicely pointed out, with a step length of 1.7548 um (which is indeed most probably way to small) and the controller would want to move the head 100 mm it will have to send 56,986 pulses to the driver (or being exact: 56,986 * 1.7648 um = 99,999 um = 99.999 mm).

If this would be correct with your driver being set to 25,600 pulses per revolution and you reduce this on the driver to 12,800 pulses per revolution, the head would actually move 200 mm instead of 100 mm and if you have set the speed to 250 mm/s it would actually move 500 mm/s! You should easily be able to see this effect if you measure the requested moving distance (like 100 mm) and see what the actual movement is.

I’m quite sure that this is the cause you get a wired noise from the steppers if you set the pulses per revolution “too low” as this would end up in a very high speed for your steppers. Reducing it from 25,600 to 6,400 without changing the step length accordingly and still assuming the moving distance was correct with the 25,600 and a set speed of 250 mm/s your head would actually have to move with 1000 mm/s (1 m/s)!

Yet again, if the actual moving distance would be correct with your current setup (which is quite unlikely as you have said that you have never tuned it), you would have to double your step length in the controller if you reduce the steps per revolution by half and so on…

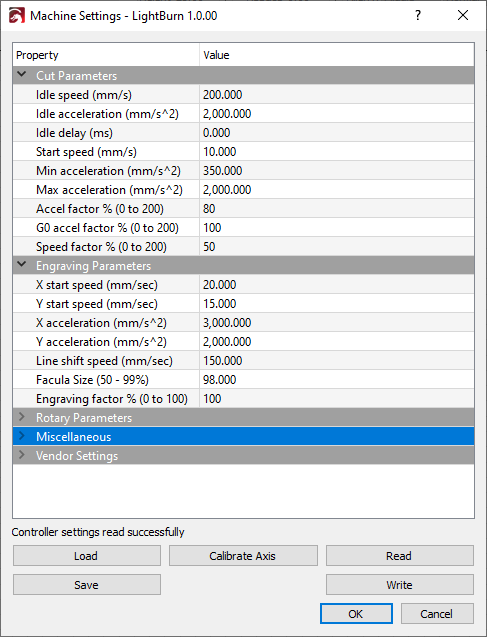

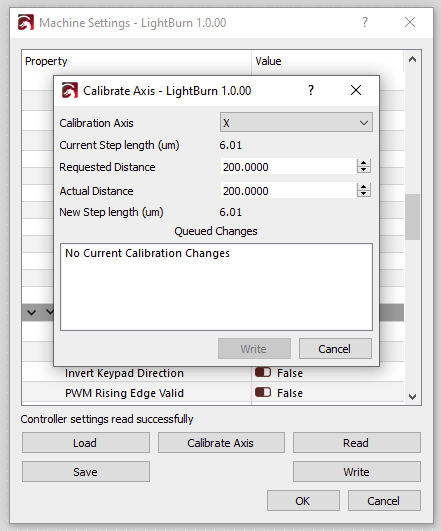

But as you most likely never have tuned your step length you really just should do that first! So set the steps per revolution in your driver to 2000 as @Hank suggested (and I do agree with him that higher is not necessarily better in this case), set your steps length in the controller to say 20.0 and after that start to calibrate that value. Either with the calibration within the Ruida DSP or with the build in feature from LigthBurn under Machine Settings > Calibrate Axis:

And don’t hesitate to ask if something is unclear to you or you have further questions to this!

Good luck and cheers,

Brian