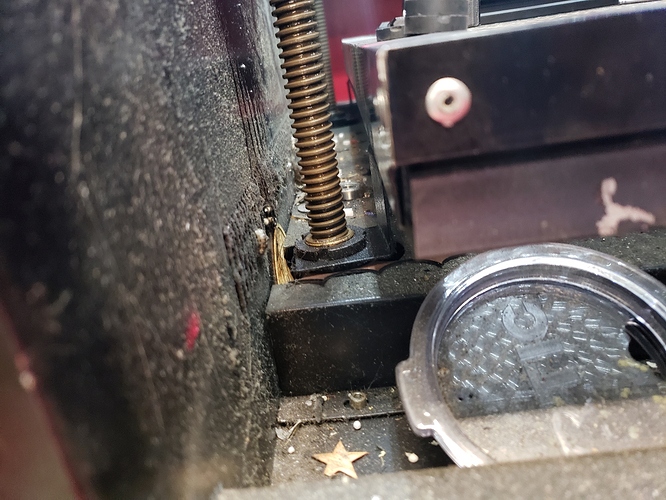

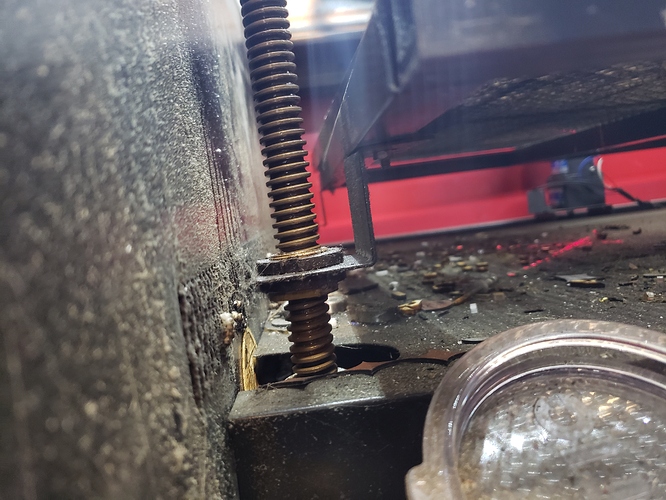

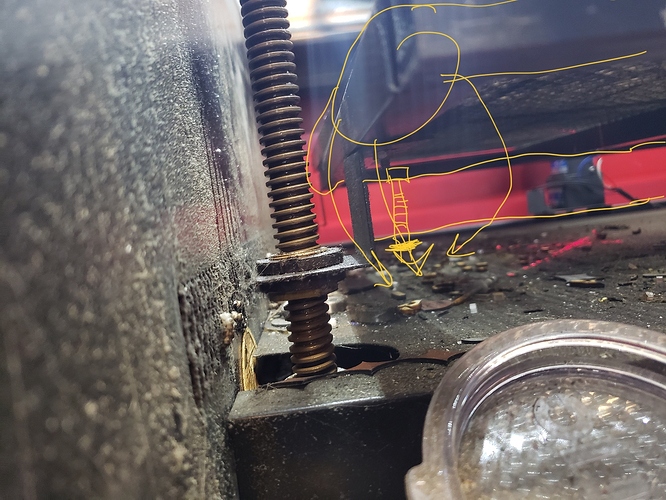

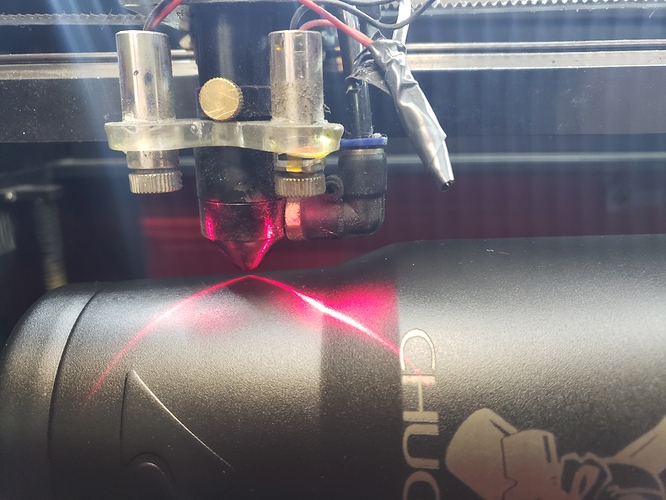

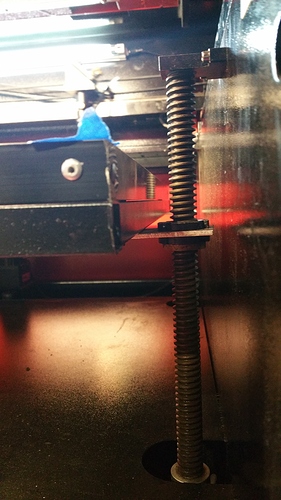

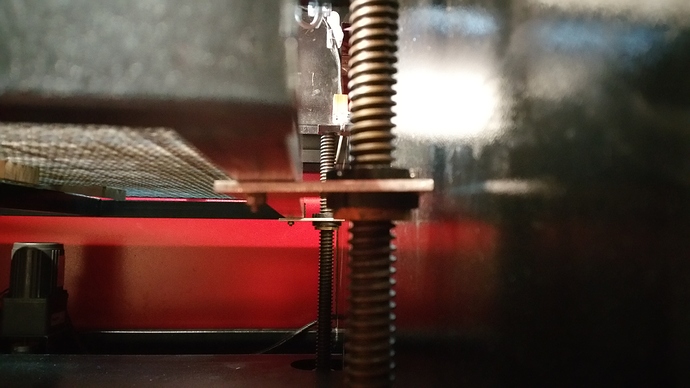

Who else has a red and black 700x500 machine? I’d like to see your bed and how it attaches to the z screws? Mine has a brackets that keep the bed frame from going all the way down. But I have an issue with my new rotary and 30 oz cups, the laser head is right on the cup. I was wondering if I could flip the bed frame over and gain 2 inches. This make sense?

On my 7050 the table is wider and the nut is attached to the table frame instead of tabs.

Sometimes I have to wonder if any 2 are made the same. LOL… china.

Clearly they aren’t, I’m about to attempt flipping mine over so I can gain that extra 2 inches. I figure I can lower the laser head nozzel to make up the difference when needed.

How about mounting the table under the bracket

Another option it seems to be the same thickness as the height on the bracket.

Sasquatch

“Consistency is for the weak.”

The whole red/black, white/blue, black/yellow etc colors used to kinda help identifying what you could expect under the hood but then, of course, “people think this color combo is good equipment, so we’ll change up the paint…”

My Red/Black 700x500mm has 300+mm of Z-axis travel. Of note is that mine came with a blade bed with the honeycomb installed on top of it. It looks like it is similar to, yet still different from @Hank’s design.

As long as you have the physical room to do so (no interference/collision) go to town. Half the fun is modifying these things to do what YOU want them to do.

Hello Hank,

I have a green and black laser 700 x 500 but it’s all the same.

Yes, you can mount it under the brackets I have done it for the same reason, why not use the extra space.

The only problem I had was that the honnycomb was a little too wide. I removed the U-profiles, shorten them and rebuild the frame. I could compress the honnycomb into the new frame so there was no need to cut the honnycomb (lucky me).

Succes Henk

I just got the brackets flipped and ran into the same problem with the honeycomb bed being a bit to wide. I have no way to rebuild the bed myself, so I am headed to find me a thin piece of metal to put on the frame and bang on.

If this is a chuck style rotary, can you rotate the rotary on to its side? That is what I have to do for 30 oz cups.

I got my honeycomb to finally fit, only took a BFH. Guess like a glove now.

I have a Chinese Red and Black 700x500 as well. I made new straight mounting brackets to solve this issue. I found that flipping the brackets would have caused interference at the top. I would not have been able to raise the bed high enough without lowering the lens, which seemed counter-productive. I made them from some leftover flat aluminum stock I had gotten from my local Ace Hardware. Just used a drill, hacksaw, Dremel and a file.

Other mods I’ve made were to add an ammeter, add an air assist solenoid valve, use an unutilized rocker switch on the front panel to override the air assist control valve since mine was normally closed so I can use it when cutting something manually, move the Y-axis home sensor to gain an additional 30+ mm (which makes my machine a 700x530 I guess), add a Lightburn camera, add additional interior lighting, add a beam combiner with a co-axial red LED pointer.

I also reworked an old Epilog edge-wheel type rotary (got it free) to work with the the Red & Black so I have both a chuck and and edge-wheel rotaries.

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.