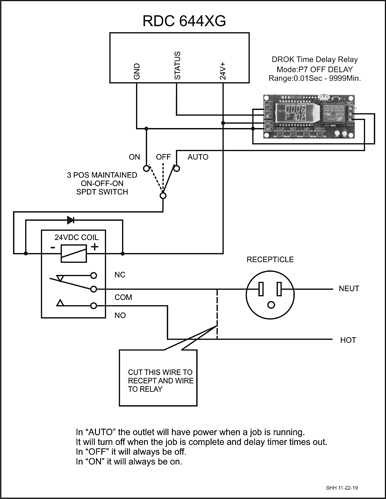

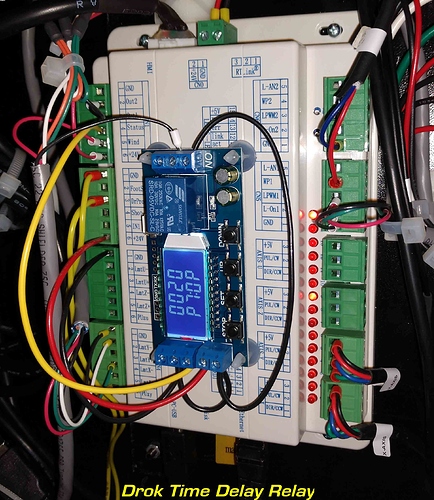

I took thx suggestion and added a time delay relay. I found this Drok relay on Amazon for less than $14. The relay came with standoffs so it was attached to the front of the controller with VHB tape. The delay time is easily adjustable. Use the P7 mode for a off-delay timer. The 24VDC was taken right off the control board.