Hi all

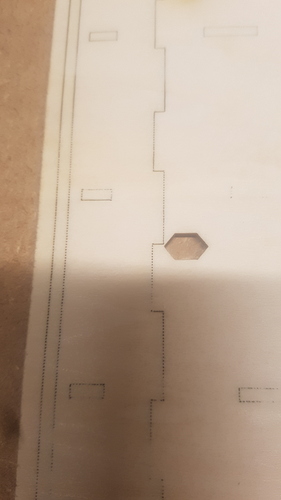

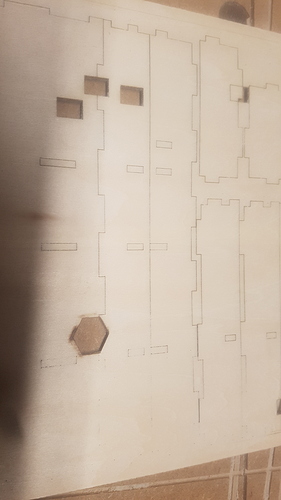

I had/have an issue. Cuts failed as it travelled down a4 pieve of ply. Through cuts ceased to cut and ended up looking like perforated lines just before failing to penetrate at all. I noted that the front of my bed was 2mm lower than the back (Which cut perfectly). I raised the bed 1mm to temporarily balance inperfection. I also slowed the cut down a few mm and now it cuts fine.

However, have I just stuck a plaster over something more serious I need to sort?

Chinese 50w orange and white laser.

With thanks

Dee

Can you post the file you were cutting? There are settings that could do this - perforation mode, dot mode, and automatic tabs could all do this.

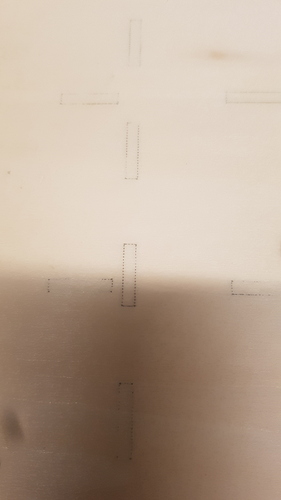

You have nothing strange in the file as far as I can tell. Are the images shown from the back side of the piece? If so, it could just be grain density variation making those dots on the back.

Thanks for checking. Yes, itsvrhe reverse of the piece. I set up the test again using some scrap. Two runs, one was perfect cut. I sped up the laser by an extra 3mmps and I got the perforated edges. So it must be a speed thing?

Increasing the speed lowers the amount of power deposited on a given part of the material, so if all you did was increase the speed, try increasing the power by the same ratio. For example, if your power was 50%, and your speed was 20 mm/sec, increasing the speed by 3mm/sec is a 15% increase, so bump the speed to 58% (roughly 15% more than 50).

Thank you.

Strangely I did another box insert with a number of pieces all of which cut through cleanly. Apart from one two inch square piece, half way down the page. It adopted the perforated finish and didn’t cut through.

I ran the file again and no such issue. So a mix of power to speed ratio and perhaps variation in ply density/glue within the piece?

Nearly all plywood is pretty on the faces and a mixture of various garbage inside - they use random fillers, glues, patches, and so on. Unless you’re buying laser-specific plywood, it’s a crap shoot. I often end up with half-inch sections that don’t cut past the outer layer, and find there’s something almost like plaster in there.

Thank you, I repeated the experiment with mdf, again the faster speed created a cut on the top and perforated on the bottom. Therefore it must be the speed. Looks like the laser is pulsing and anything over 22mmps is too fast for the laser.

Are you using an aquarium pump for air assist? I’m thinking it could be the pulses from that causing the cutting efficiency to pulse.

That’s interesting, i am using the pulse pump. I’ll turn it off and try it again. Good hypothesis! Let’s see.

Turned pump off, same dots appear.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.