A closed water cooler is not a guarantee that there will be no air bubbles. I have a CW5000 and after a day’s production stop there are often microbubbles that collect in front of the small glass tube at the exit side. A few small presses on the hoses “loosen” the bubbles in my system. 30mA is a lot, what does your test shot look like from the nozzle? Do you have a spare lens you could try? Please specify units according to the values, it makes it easy for everyone. Can you take a few pictures of your test shots?

In my opinion something is wrong with the tube, possibly power supply, but I would suspect the tube.

At 30ma, using a tube that large, the beam should blast thru multiple sheets.

Be interesting to hear what others think.

I use a CW5200 and i just did what you said and squeezed the tubes

are you talking about a pulse from the machine

does anyone know of someone in the San Diego CA. area that has this kind of machine that may be able to come by and help. I know its a longshot but its worth a try

Have there been air bubbles?

By test shot, I mean something that shows yourself and us what a pulse, long or short, out of your nozzle looks like.

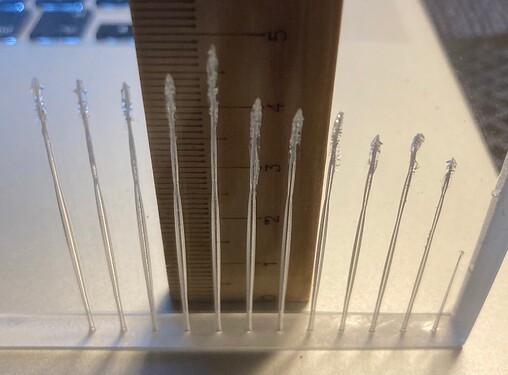

I once did a test with my laser to find out where the limit of mA versus% power is. See Attached Image. Acrylic is always a good diagnostic material for a laser.

Good night for today.

The only name I know out west is Lightobject out of Sacramento Ca. Not located near you but they may have service technicians in various locations in the state. Or recommend someone. Good luck.

I also want to add one more thing…I HAVE had some birch ply that I couldn’t cut through at 13 mm/s @ 65%. I just ran into it again today. The core was too airy, and actually charred like hell. The line on the top widened more than usual. And I could barely cut through on a 2nd pass… actually, I just threw it away… so maybe it is just bad ply…

May I ask if the machine has ever run “normally” with you and if you have done a ramp test recently?

i dont think this machine is at its full potential, oh and while i have the attention of everyone here thank you for all the input everyone is awsome, i have noticed yesterday that my air assist is not as strong now at the nozzle, what can i do to fix this? i could hear the pressure of air when i focused but now i can barely hear it

I want to start by seeing if there is a “constipation” somewhere or a kink on the air hose and the nozzle itself - it also needs to be checked. In the end, if everything is ok, then there is only your compressor left which could be on its way to the eternal hunting grounds.

this machine is not even 6 months old

… I’m not saying it’s broken, but the probability is not impossible either. Try to troubleshoot.

Did you check your lens? Mine wouldn’t cut and turned out that I was unaware that I had to empty my air compressor (from the bottom daily) or so was just told to me… and it busted my lens… ordering tomorrow… hope you got it fixed.

Hi Mark,

I suspect that 30mA might be a bit high for your tube. Not disastrous, but more than recommended. My tube was sold (by a Chinese eBay vendor) as 100W but in reality it’s 90W, able to achieve 100W at the expense of a shortened lifespan.

For my RECI tube, 24mA is the maximum recommended current. I make sure I don’t exceed that ever.

I had a tube problem when I first got my machine. I noticed that the minimum firing power was increasing. It started at 9% when the tube was new and had increased to 15% when I realised the tube was failing. Not everyone tests this, but do you happen to know if your minimum firing power has increased?

You can also temporarily remove the cone from your laser head to see if the beam is hitting the cone. You won’t have air assist without it, but you’ll know that 100% of your beam is hitting the material.

The other question I have is “what works?”. Can you cut other materials? How do you go with MDF, for example?

… Mark does not give us many balls to play with.

I cut at speed 15 power 30 with a 70 watt machine. Verify focus, clean lens and check to ensure correct side is facing up. Never had to use that much power to cut.

i dont even know where to begin

This thread has me nervous. I have a 130w chinese laser. It seems I cut through 5mm plywood with no problem. The think I am nervous about is I cut at 60% power and it is registering at about 21-26 mW depending the temperature in my garage. Is that pushing my tube too hard? Should 60% power on a 130 laser tube be set to a lower wattage? My power supply is for a 150w laser tube.

Should I start a new thread. Not trying to Hijack here. I thought my question was somewhat related and relevant for the conversation.

I just installed a 90w tube and can cut home depot hobby ply at 5m and my meter says 5ma.

We should all save test material that you can use to check power periodically Your power seems very high but it depends on how much time you have in it.