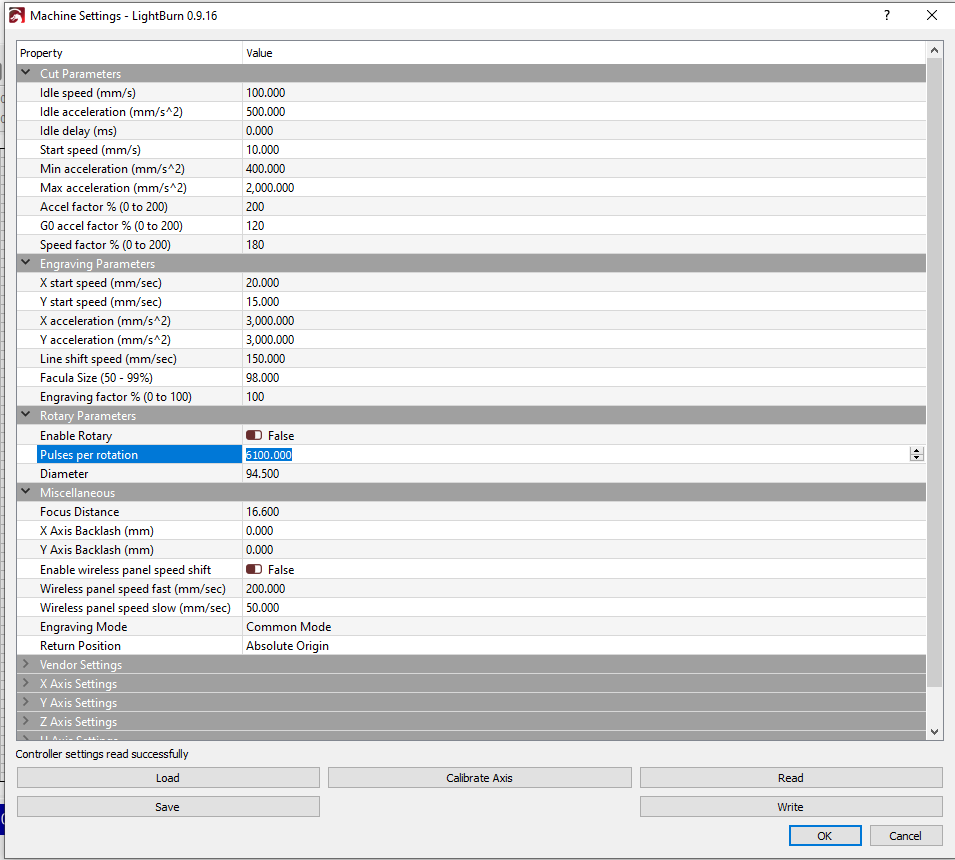

Try changing the Y acceleration in the Engraving Parameters section to 1500, and change the Line Shift Speed value to 100. Try those and see if that improves things.

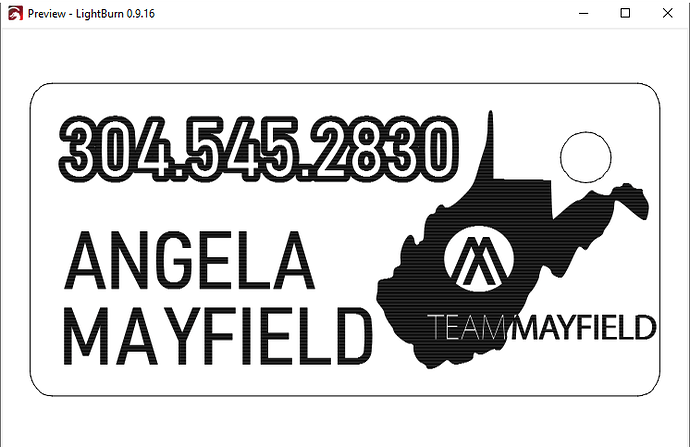

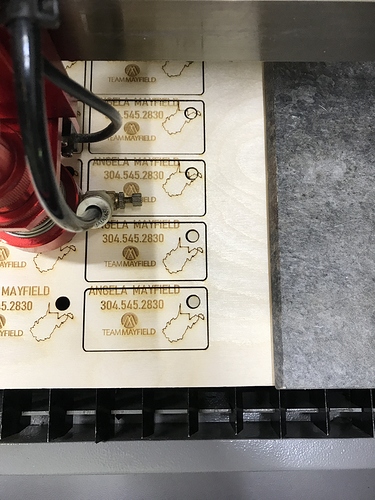

Design didn’t have any odd or hidden elements in it. Here it is with the rows and columns.

RBHM1PWMC.lbrn (3.7 MB)

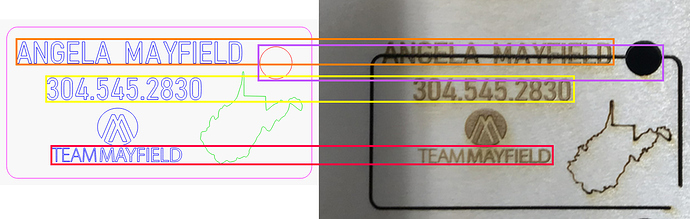

I did that , running it now here is a picture of what it is supposed to look like

I know I sound stupid how do I load yours into my machine just save and open?

Yes, download the file to your machine and open it. I still had your file open a few minutes ago when I came back to my computer, and just for the sake of experimentation I started to test spacing, positions, etc.

After I was all done playing around, I compared my end result with yours, and I think your design is better. Your design is much cleaner and less cluttered than my catastrophe.

RBHM1PWMC-02.lbrn (354.2 KB)

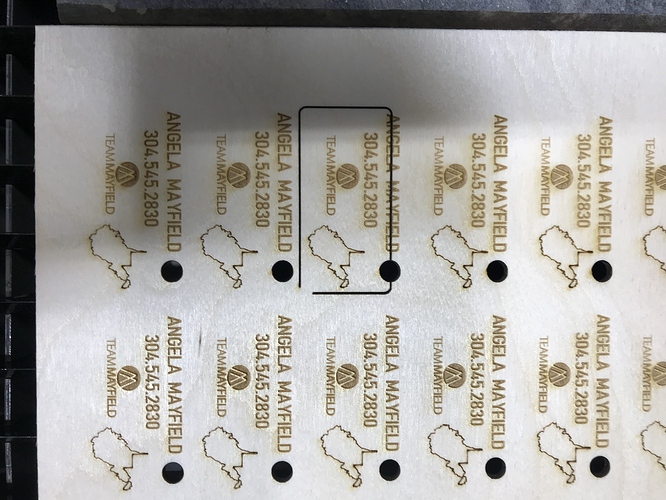

What’s so funny is I’ve never had this before draw a tag hit rows and colums and it did it !

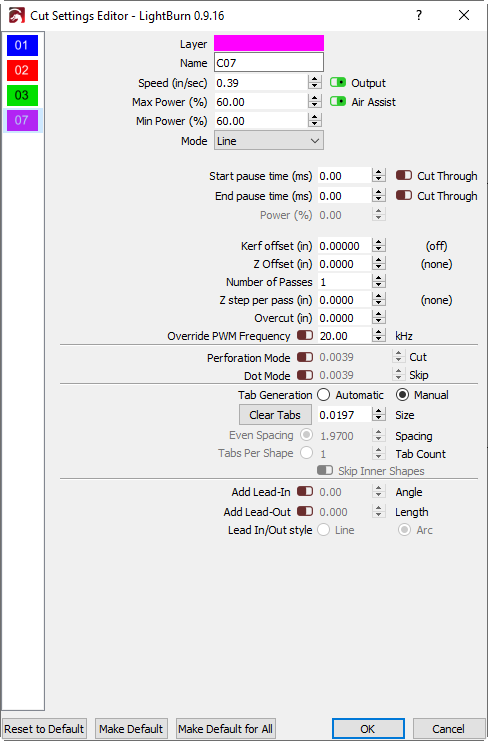

Can you screen shot your setting for layer 07 (the cut out)?

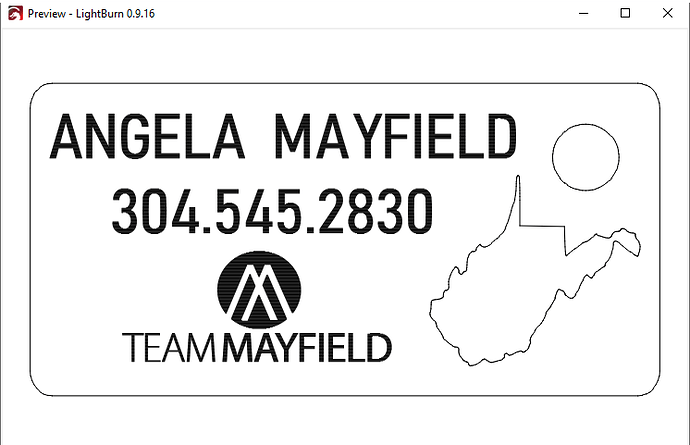

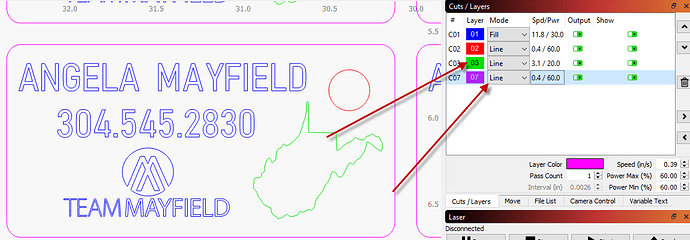

It looks like those last two line layers are heavily shifted down. BUT, layer 2 is not. So this really places doubt on it being an issue caused by skipped steps or the like due to over acceleration in the fill layer.

If you look this time the WV droped down too

Trying yours now wiring to See what is does

But on closer inspection, all of your line layers are shifting down (even layer 02). Layer 02 just isn’t as much:

I got about a 100 done before today on time it worked another it doesn’t I’m wondering if the file is corrupt some how. Couple times went back to original art work cut two sheets then it would start this crap again

Those are all good too Not going to show my client shell want to chance LOL

There’s a way you can probably make this work that won’t fix the problem, but will get you through the job:

- Group a single keychain, THEN do the grid, so each item in the grid is a group

- Go through all the fill layers and set them to Fill groups together, instead of “Fill all shapes at once”

- Click the ‘Optimization Settings’ button in the laser window, and click ‘Order by group’ twice, so it’s the FIRST thing in the list. That will complete each grouped item before moving on to the next.

Thanks I’ll try that’s

Thank you very much the grouping in the manor you said fixed everything ! Light burn people are always helpful and so are the other members here to jump in.

@Oz was correct (again). It’s like the guy wrote the software… oh wait.

So, long term solution here is to determine what the root cause is.

Could be stepper driver configuration, motor, belt, axis config, or even a loose screw or two.

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.