I am trying to cut through 6mm walnut with my Atomstak X7 M40 without using high figure passes

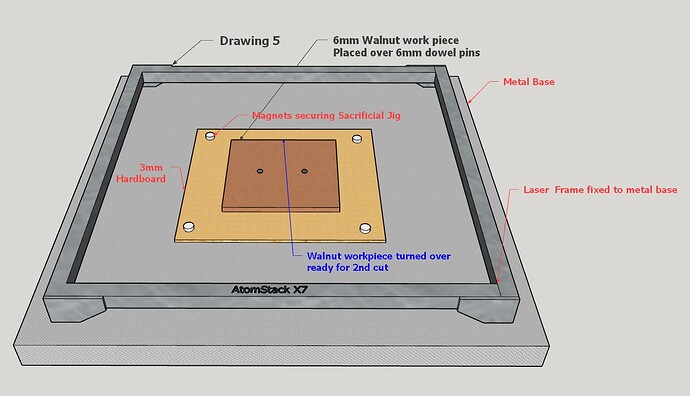

I have a jig where i can place the material reliably and allows for the material to be flipped with a high degree of accuracy.

The problem I am having is that the cuts do not allign.

It appears that the machines work area and what I see on the computer screen do not match.

Any advise would be appreciated.

I think you will have to be a little more detailed in your explanation… a few photos might help also…

How and what do you have for a jig ?

How far off is the cut?

![]()

Here is a link on the Ortur Facebook page on how I do double sided burns. Easy to do and works every time.

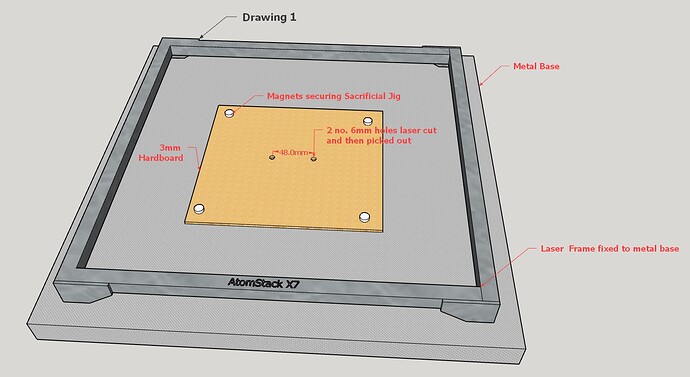

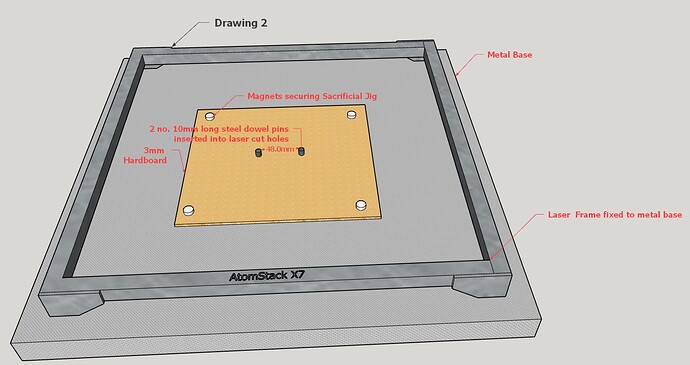

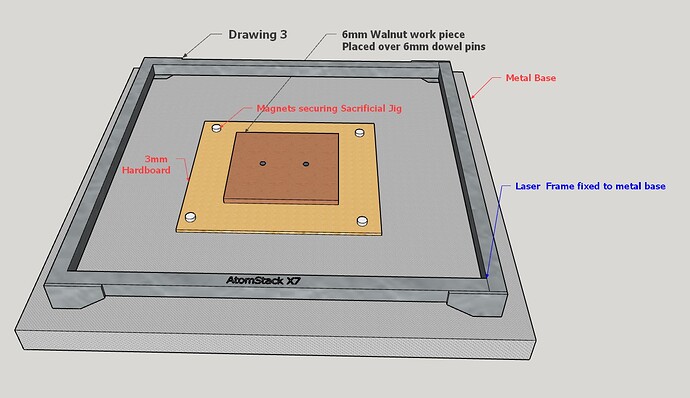

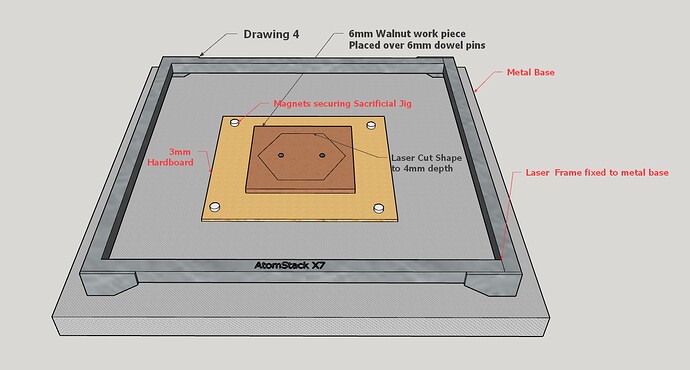

Hopefully these series of drawings explain what I am attempting.

I have realised there may be error introduced when re-setting the laser focus to the 6mm walnut workpiece

The error on the X axis is around 1.6mm

You are securing the scrap board with magnets? How do you setup where the scrap board is located.?

Do you put your design on the cut out diamond…

![]()

yes, the 3mm hardboard is held securely by strong magnets.

The laser frame is fixed to the metal base therefore any design should be repeatable

I dont think it matters where the scrap board is located, as long as it covers the area to be used.

All designs are drawn and located to dead centre of laser work space in Lightburn.

In the example drawings it is the hexagon shape that is to be cut out and is the end product.

The laser will not cut through 6mm Walnut in a reasonable amount of passses but it will cut out shapes using 1 pass per side which saves an awful lot of time - my problem is trying to figure out how to calibrate the laser to do this!

You cut part way on one side then flip it over on the pegs for alignment on the other side…for the final cut?

![]()

Yes, that’s correct.

It sounds like you have the theory down OK. I can only image it’s not snug enough to maintain the accuracy you need.

I have holes in my steel bed, that I use to align jigs… I don’t know if they are so accurate that an eye couldn’t ascertain it isn’t aligned perfectly.

Are you just ‘re-running’ the original code.?

I’d have to say it’s not located correctly… Can you determine the direction it’s off?

![]()

I would think your dowels are off by 0.8mm in the X from machine centre. From what I can understand…

Make sure the laser head is square to the bed. If it’s at an angle that might account for the difference as well.

I have just carried out another test using a new drawing and this time it has performed perfectly.

Not sure if there was a glitch in the gcode previously.

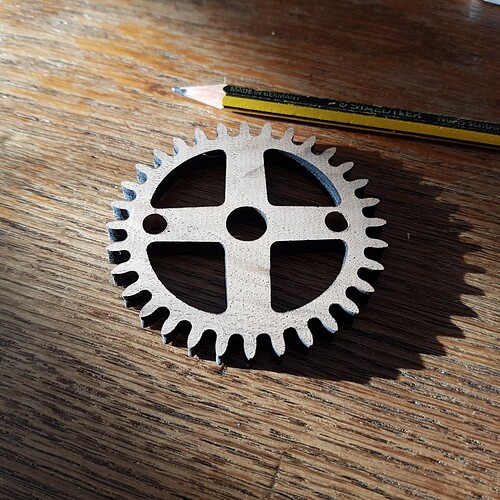

I shall post a picture of an actual component tomorrow.

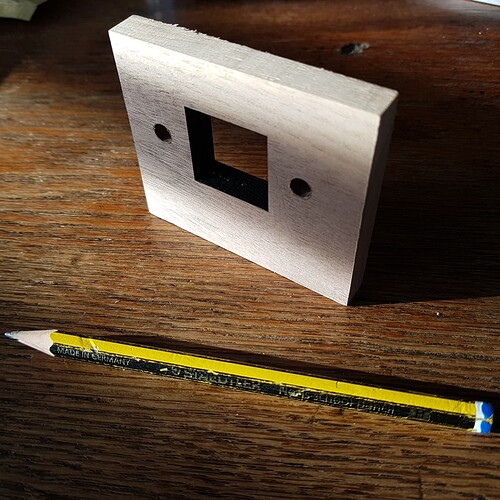

This jig should give the possibility of cutting 6mm walnut in a reasonable amount of time.

I will also see how thick it will cut using 2 passes per side.

The 6mm thick cog took a total of 12 minutes and 16 seconds using 120mm/min @100% power and 1 pass per side

The 25mm cut out in 10mm walnut took 3 minutes and 22 seconds using 120mm/min @ 100% power with 2 passes per side

Looks great… would make a nice clock gear…

![]()