hmmm I am suppling 0-10volts between the pmw and ground and i believe i have all the settings correct and i can not adjust the speed of the spindle by varying the voltage. I am supplying it from an adjustable testing power supply

You should be using the analog inputs for a dc supply, not the pwm. Most of these motor controllers want a 0 to 10V input range.

PWM input might go through other electronics that won’t function with a dc supply.

The pwm inputs have no specifications about what the voltage swing needs to be.

![]()

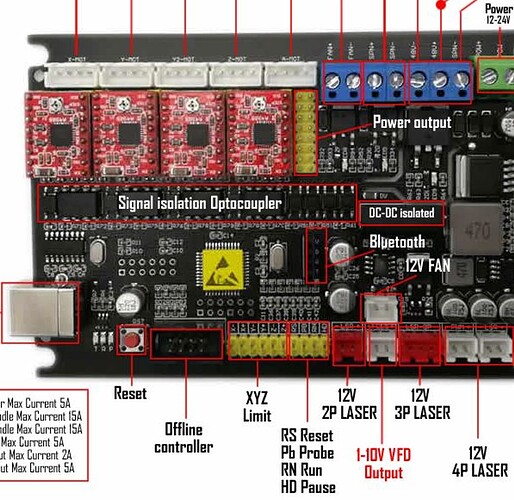

let me see if i am understanding correctly. after making sure all the parameters are set for a 10v pmw. that using a dc power supply isn’t working as it is the wrong source, I was hoping to minimalize the expose this new control board would be associated to just for the testing phase. my new board actually has a vfd 0-10volt source

well hooked it up to board and been trying variable spindle speeds from the gcode and can go from 1-10volts and no changes. I am still hooked to the pmw and the ground

Do you mean the output doesn’t change?

If you’re going to use the analog output of the control board, you can’t use the pwm inputs to the motor speed control, you have to use the analog input.

![]()

no change is even when i can adjust through the spindle speed control and set at 2 volts or even 10 volts it runs the same speed, i know that that the speed control for analog ( I assume using a 10k rheostat is what you mean) that the pmw can’t be used

The control board should output an analog voltage related to the speed settings. If this is working that only leaves the control box.

I’d look at the module that’s running the motor. Either it has a problem or you have wired it up incorrectly.

![]()

my gut is absolutely telling me that if i have the parameter’s right and i am getting 1-10 volts to the vfd it should be mirroring the change but the manual is a far site below what i am used to with all the vfd’s i have installed and ran in industrial applications and i have a neurological pathway issue that makes it hard to remember and makes me make a lot more mistakes then I normally would.

besides the company i bought it from has “send everything to the engineers” and they even wanted a video and i have no idea of what so i shot a video of the readout not changing lol

They wanted video and pics of a USB drive I did not receive, so I sent them pics of my empty hand and empty USB ports, still didn’t do any good, they would only send one file at a time, ended up finding someone with same machine and got a copy of the files that way.

lol i had to do something similiar once lol

Did you set minimum/maximum spindle speeds on the controller?

Sooo… is it working?

![]()