Hi people,

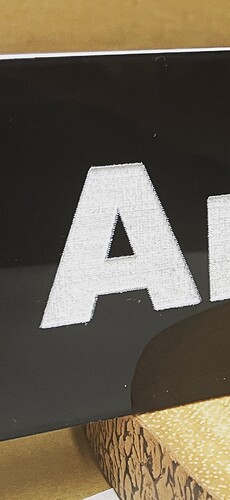

I engraved this sign 16 inches x 3 inches for a customer but I’m not happy with the finish. The lines seem very pronounced, any ideas on the settings I should tweak?

looks like backlash to me. The ‘overhang’ on each side are different ‘lines’ and are offset. Much more on the right than the left…

Might let us know which machine this is.

![]()

This is a 60w Omtech Blue, any ideas on the settings which need adjusting?

You can start by sharing your settings with us, then we have a starting point.

As @jkwilborn writes, one of the problems is the backlash of your machine at the speed used.

Apologies, I should have known better. So it’s a 60w co2, 4mm 2 ply laminate. Setting used 200mm/s@55%max 20%min power with 0.2 intervals and cross-hatch enabled.

Have you checked the backlash? It’s ‘hanging’ over the edge…

You have min power set, is this a vector/fill or image?

Any particular reason for crosshatch?

Is this acrylic or some other kind of plastic?

![]()

Thanks for the reply Jack. It’s a vector fill. With the standard back and forth horizontal areas of black could be seen. The crosshatch helped clear more of the remaining black. The material is a plastic laminate, a thin top black layer with white underneath. In regards to min setting, this was a suggestion on another youtube video, but could possibly be the problem.

I would recommend a line spacing of 0.25-0.35mm when using crosshatch 45 degree and less power. Why do you use 20% minimum power?

To correct for backlash, run some tests and insert the values you find in the backslash compensation settings for the different speeds.

Minimum power is only used when the head is changing speeds, most commonly with vectors.

If it’s scanning like normal, it’s probably computed the overscan.

You can watch the head and see if it’s traveling past the edge while not firing.

Take great care cutting unknown kinds of plastics. Most seem to produce gases that can be corrosive on the machine or poisonous to life.

Good luck

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.