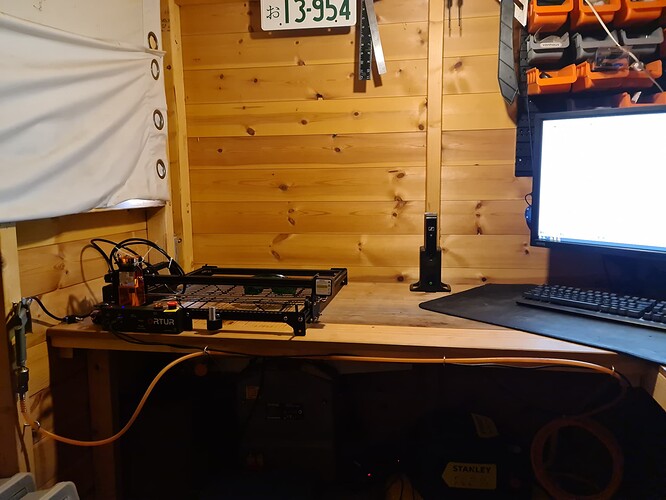

I set it up with what i had to hand, wow the difference is amazing.

Compressor set to 15psi > orange cable > blower that came with the Compressor with the 1/8th inch connector inserted instead of the blower nossel > black ortur pipe > ortur mini regulator > black pipe > ortur air assist nossel.

Wow you werent lying about the pencil lines, it cuts through 4mm ply in 2 to 3 passes with zero burning around the edges at about 0.3mm… i was struggling to get through in about 30 passes before.

Packet of rizlas for size comparison and a pendant ive just made for the mrs ![]()