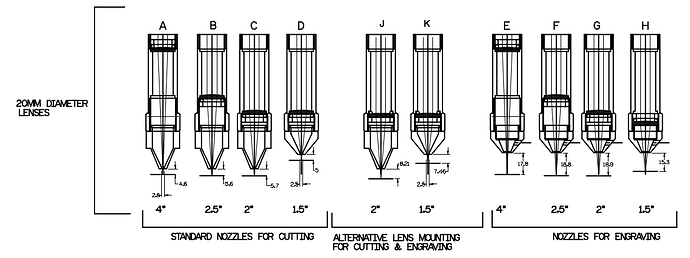

Sorry this might be a dumb question. But is there a way to determine the focal length of the lens and holder by examining the dimensions of the nozzle?

Shorter lenses usually require a larger hole.

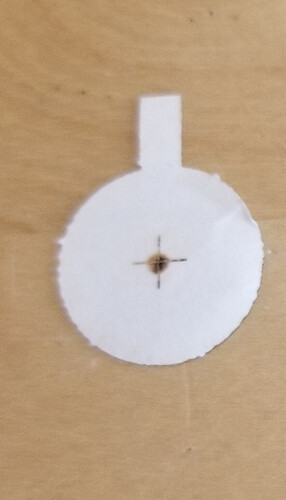

A ramp test is the best way, you can post it here and let us have a look at the beam mark…

Ensure that lens isn’t sitting at an angle within the tube and is secure.

I’d still like a better photo/exposure of the m1 test.

This is a target from m2, with both a short and far pulse…

This is an m1 pulse when I noticed the tube going out of TEM00 resonance.

![]()

if I don’t know the focal length of a lens here is how I would determine the length.

there are 4 common focal lengths you will find in co2 lasers, 1.5", 2", 2.5" & 4".

the most common is 2.5" & that’s where I would start.

I would place a piece of material down on the bed, MDF, would be fine, and remove the nozzle from the laser head. That will allow you to get a decent measurement from the top of the material to the bottom face of the lens. Adjust the height of the lens to 2.5" from the surface of the material. close the cover and fire a single pulse. I would then move thee head over a 1/4" and readjust the height to 2" and fire another pulse. if the second pulse is larger than the first pulse then raise the height to 3", if it is smaller then lower it to 1.5".

You are looking for the smallest dot size. if the 2.5" dot is smaller than the 3" and the 2" dot the lens is most likely a 2.5" lens. if the 1.5" dot is the smallest then it is a 1.5’ lens.

They are pretty much in increments of 12.5mm or 1/2 inch.

If you do a ramp test, you know the distance to the nozzle. Use anything to measure from the nozzle to the approximate lens position. I think you can tell the difference of a half inch…

Don’t over complicate this stuff, it’s technical enough without adding extraneous data or procedures in the operation.

Unless you have multiple lenses, you have what you have, learn to use it no matter what it’s focal length is…

Mine came with a 1.5" lens, it’s an OMTech China Blue…

I probably use the 2" the most for general work and the compound for more detail… 4" for thicker material.

Good luck

![]()

My main concern is I have a lens that is incorrectly sized for the nozzle. Not sure if the ramp test would show this.

If this is a factory machine, I’d think it would be right or it would have had issues from day one.

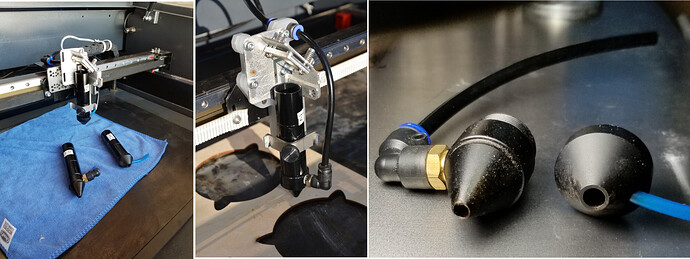

You can remove the nozzle, apply tape there, and pulse the machine. It should be centered in the area.

Also put tape over the nozzle tip and pulse it. You can see if anything is off…

Russ Sadler made this tool for checking the beam being centered in the nozzle. Of course, you need a working machine to cut it out of acrylic ![]()

Beam Checker 2.lbrn2 (12.2 KB)

Photo on the right is the two nozzles that I use. The short wide one is effective with shorter lenses. Here is a relative chart that gives you and idea on configuration of these…

Let us know…

![]()

This did the trick. It’s was a 2” lens. Got it dialed in with this technique and I’m cutting and engraving away.

Thank you for your time.

Excellent!

" May your works be great,

may your waste be small &

your mistakes be few and far between"

Rob