SKR 1.3 32bit 100mhz Controller. I don’t want to judge it too soon and before i will have a PC 1m away with a good USB cable. so far i am very happy.

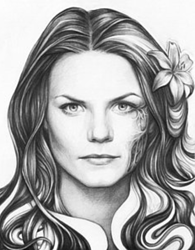

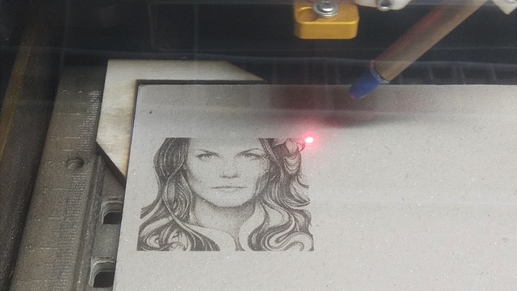

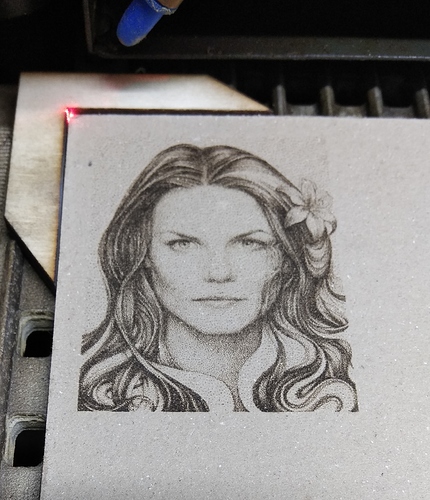

This is an image i just downloaded from the internet and without changing any settings from my grayscale calibration image, this is what I’m getting (On a gray 2mm EskaBoard):

I am very pleased.