I’m running a 2.8w Jtech diode laser on my Shapeoko 3 XL (SO3) running on the OEM GRBL board (2.4e), GRBL 1.1 firmware, and LightBurn 0.9.15 on Windows 10.

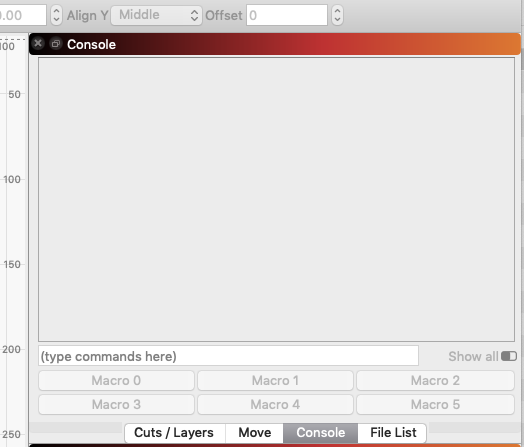

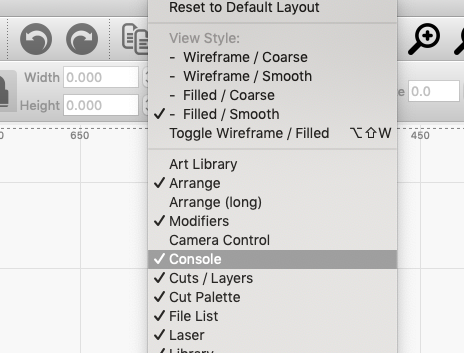

I don’t have much seat time with my laser as I tend to use my CNC router more; however, I’ve come across an issue that I haven’t encountered before. I’m currently endeavoring to laser engrave a test photo, but at approximately the 30min mark, the laser stops. The software is still open; run time clock running; SO3 is still connected to the software; Console window doesn’t show any errors or messages - just shows the last gcode line (i.e. G1X-0.024S0); and if I depress “Pause” then “Resume”, the laser will actually resume but only for a short random duration (a line or a few). Cycling “Pause” then “Resume” no longer works to get the job going if done in quick succession.

Notables:

- Changes that I’ve recently made… switched to a VFD powered spindle setup (relocated the laser’s PWM and GND wires) and updated to LightBurn 0.9.15.

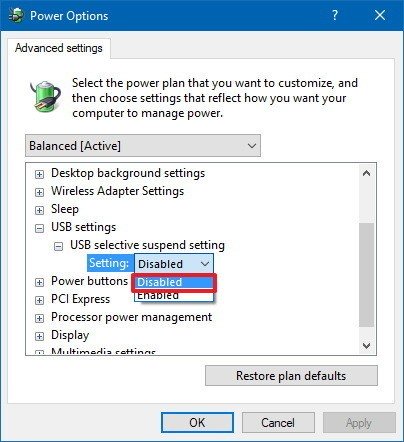

*Tested moving the PWM and GND source back to the location I had it before, and removed the spindle from PWM and GND wires from the board - no change. - Looking into my Power Options; I’ve been on a custom plan that doesn’t put my computer to sleep or allow USB selective suspension. I’ve experienced a USB related issue while CNC milling, but haven’t since I had changed my computer’s power plan over a year ago.

- I tried staying on my computer while the laser was running to keep everything “awake” - no change.

- Isolated and placed the laser power and SO3 power on separate power sources.

- Laser the photo with a different scan angle to see if there was something inherent in the photo - engraved different portion but still stopped ~30min in.

- Tried engraving faster - it does get further but still stops ~30 min in.

- Cut settings are 125in/min, 100% power, .008in line interval, 125DPI, Scan Angle: 0deg, Image Mode: Jarvis, Number of Passes: 1, and preview estimates a total time of 1:05:19.

- GRBL settings: