I have seen PSupplies that could be adjusted to flatten out at the max ‘safe’ current by the vendor [Bodor]. The tube and PS were Reci, btw. And a Automation Tech laser I bought had a POT to decrease the tube power, altho I did not have time to explore how it worked, that one had a 100w Reci also but a Chinese mystery PS.

Current is equal everywhere in a series circuit, voltage however gets used up. There may be tens of thousands of Volts on the input side but on the ground side there is zero Volts. Just make sure you know which side to put the meter.

Not really used up, it’s more like divided. In this case, where with have an extremely high resistance in the tube, and almost now resistance in the ampmeter, it will be divided so that almsot all the voltage is over the tube. It doesn’t matter which side you put it on.

If you attach the multimeter to the positive side there will be tens of thousands of volts between the multimeter and ground. If you attach to the negative side there will be close to zero.

The voltage dropped across the multimeter will remain the same in either case.

Voltage is not really “divided” in a series circuit, it is dropped (used up) across each element. You can test this by measuring the voltage at various points in a circuit, place one side at ground and probe the other points to see the differences.

Really? “Voltage Divider” is an alternate name for a series circuit in literally every electronics textbook.

And if you place the probes on either side of the element in a series circuit you can see the divided voltage.

If you attach the multimeter to the positive side there will be tens of thousands of volts between the multimeter and ground. If you attach to the negative side there will be close to zero.

True, but you don’t measure to ground, you measure between the tube and the terminal on the PSU. That’s the same regardless of which side you are on, as long as you don’t stick your fingers in there.

The return terminal on the PSU is at ground level. If you install a milliammeter to the positive side of the tube then the electrical potential between the ammeter and the chassis will be at tens of thousands of volts.

Maybe you can make it work, but it is poor practice, and you will find no factories installing the ammeters on the positive side - there is a reason, I’ve tried to explain, perhaps I have failed.

Good luck.

No, you will see the amount of voltage dropped across that element. When you are measuring between two elements and ground then you are effectively “dividing” the voltage; you are measuring at a point where some of the voltage has been dropped (used up) by the upstream elements.

I’ve heard that if you go to the Vendor Settings in RDWorks, you can set the max laser power percentage; my thought is that if I know my tube shouldn’t exceed 25mAh, I can tune it down to have that as the max and then in LightBurn, if I set something to cut at 100%, I can safely know it won’t exceed 25 mAh. Does this sound correct and has anyone done this?

Yes, this is one of the things I have done. If you change power supplies you will need to repeat the process.

If you adjust at the power supply, then if you happen to have two power supplies then you can swap them back and forth with no need for changing settings in the software.

Either way, it is a really good idea to have an ammeter installed, and checking it during operation should be a normal thing.

Mine is, and most of the ones I’ve seen I The last 20 years or so have been,

I’ve yet to find a Chinese laser that isn’t.

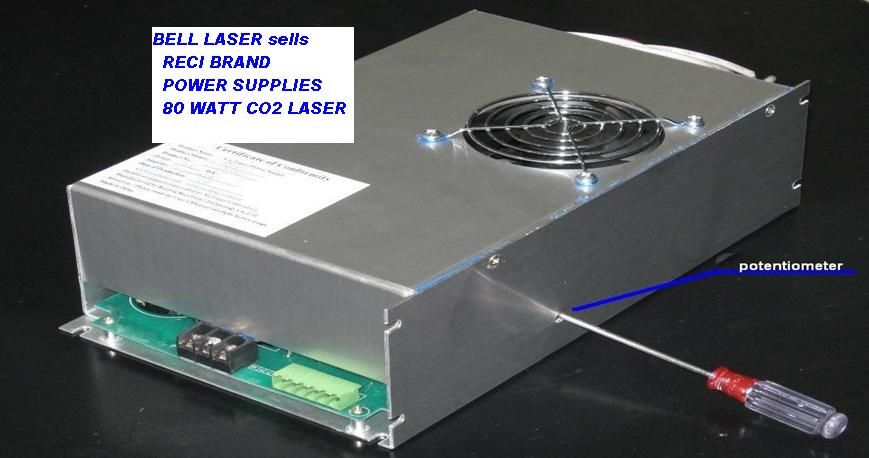

From Bell Laser (I have a HY, not Reci, but the process is the same).

The procedure is : check the manufacturers rating for your tube (my Reci W4 is calibrated at 30mA with a maximum running current of 28mA, but run at 26mA for longevity)

measure your output to the tube using a digital multimeter

Set your desired maximum by adjusting the psu potentiometer while at 100% power

Then, you will have the full range of 0-255 (or 0-100%) available to you without worrying that you might be over-driving your tube.

Here’s an instructable: https://www.instructables.com/id/How-to-test-and-set-a-Chinese-China-made-CO2-Laser/

This will work but you would be much better off just installing an analog milliammeter (0-30 or 0-50 mA). With the milliammeter installed you can not only adjust your power supply but you can also monitor the current going through the tube. It can give an early indication of tube failure.

Most people have better access to a digital multimeter than to a 0-30mA analogue ammeter.

Standard word of advice that most new users get is to install a mA meter in their laser if it did not come equipped with one. It is a cheap investment that will make things better for not overdriving tubes, being able to set the current on a K40 more accurately, and as Rich mentioned, helps to diagnose a failing tube or power supply. Well worth the little bit of effort to install one if your laser did not come equipped with one. Just my opinion.

I live in the third world. Where do I go to buy these fabled milliamp meters?

You, and the previous poster, are ‘correcting’ something that wasn’t wrong.

He wanted to know the procedure for checking/setting his laser. I gave him one, one that was correct and would give him the result he required.

Yes, fitting a meter is a good idea - it should be fitted at the factory - but that isn’t the only solution, nor the most accurate when you are dealing with very low numbers.

How accurate are sweep milliamp meters compared to my digital multimeter?

Seems like there’s a lot of willingness to wave willies around here. I think I’ll give this forum a swerve and leave it to you more argumentative types.

I did not think I was being argumentative, all I did was make a statement of something I thought was in the OP’s best interest. I was not correcting anything, just adding more information into the discussion. I even made sure to state that it was just my opinion. I am sorry if you took this to be argumentative, that was not the intention. As to your question on where to buy one, they are available on Aliexpress or Ebay. Most people have access to these online purchasing sites. They can be shipped just about anywhere in the world.

I was under the impression he wanted to solve his problem immediately, not in six weeks.

No need to fight guys, I appreciate all responses. I can sort out what’s applicable for me.

I also live in the third world (Sweden). I ordered one from China for about $4. This is for long term permanent installation.

For the short term, I’ll do tests with my digital multimeter.

LOL @ third world Sweden.

I’ll believe you when you can’t buy a metric bolt or some isopropyl or a digital multimeter. Heck, it would be nice sometimes to be able to buy some ibuprofen or a pie…

It’s rare that I can buy anything locally - I even import my wire, as the only stuff available locally is extension-cord 3-wire flex and house wiring solid-core.

Not a great place to try and run an engineering business.

LOL @ third world Sweden.

Well, first world is the countries that aligned with the west after WW2, second world is the countries that aligned with the east, which leaves neutral Sweden (and Switzerland) among the un-aligned third world.