The cat got in there? Please don’t say it was the cat!

MIKE, OMG, that should have brought my fever down a notch or so. Actually we have 7 cats and a dog… The dog is the only thing that lives with us. Cat’s have their own place.

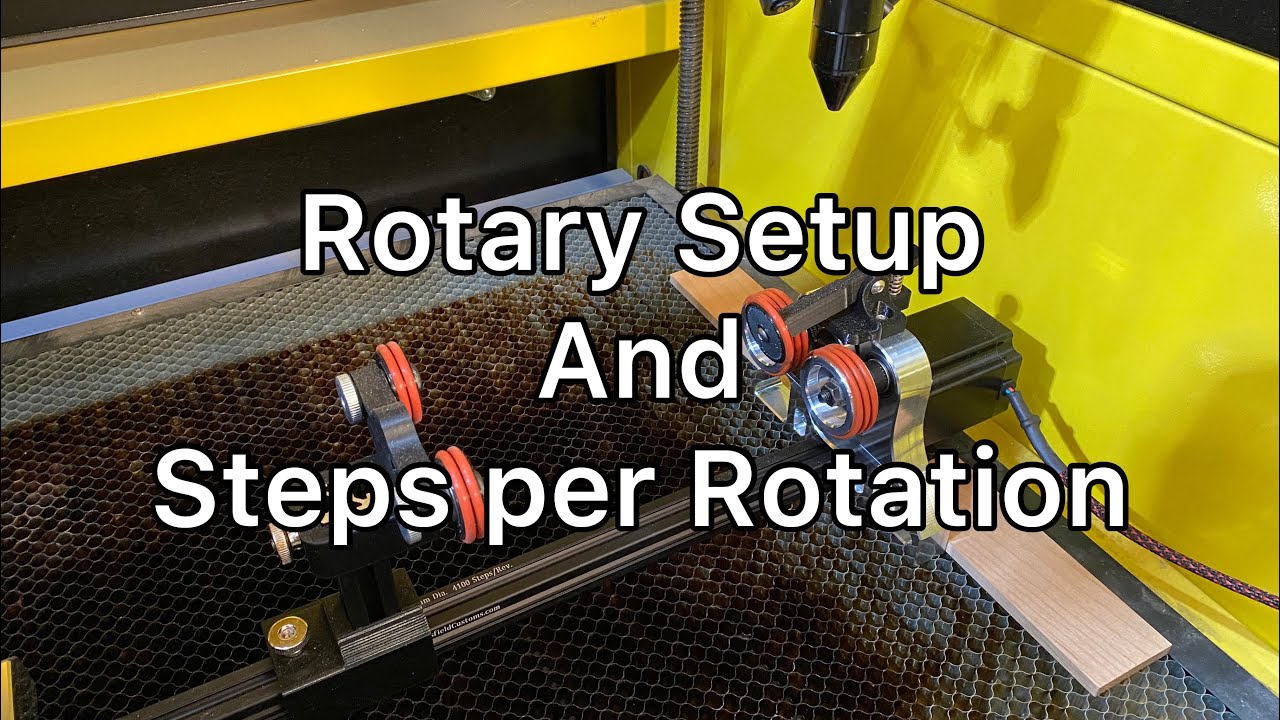

I “believe” at this time at this moment, it was my Steps Per Rotation. Jason and I have spoken allot in the past month. This is why I bought his. It’s stamped 4100 steps. Yesterday during this fiasco, we cut it in 1/2. Then got to looking at other things.

I saw this video a while back probably a month ago. He mentions about the steps being printing on it, but his controller stepper drivers I assume think otherwise.

So I changed mine to 4300. Started out 2100, then 2600, then and on up to 4300. BINGO. I don’t want to jinx anything, but it “seemed” to be the magic number.

Glad you got it going.

Strange that it only had an affect the one letter.

Yeah, and it was always the last letter in a word or the longest sentence of multiple lines. I tried 300 mm/sec, not going happen. 50 mm/sec it works fine.

I’ll live with that if I have to.

Here are the comparision.

https://drive.google.com/file/d/1lnGxQlRfJgxv_V0kcBh0fH0lsofrYDUX/view?usp=sharing

This is how you should setup your rotary for steps/rotation

![]()

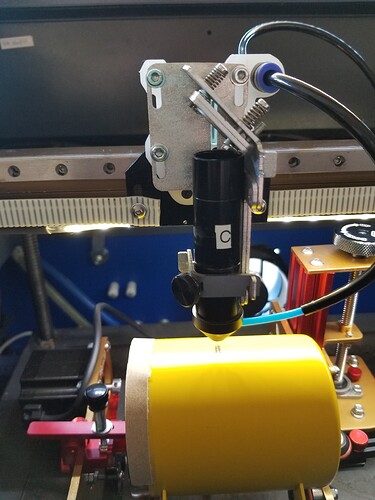

I have trashed a few tumblers from speed.

I have started putting rubber bands around them to get that bit more grip.

Still good to hear it is working!

Although I have a Ruida, the idea is the same… I have different configurations for the acceleration of the axes, that I load and write to the controller.

How fast it accelerates can toss a cup off the machine. Most of mine are in the single digits…

![]()

Hey there Jack.

Yeah, I’ve seen that, however I can’t read the legend on my drivers. It’s too far into the side of the machine, and no way on gods green earth, am I going to try to remove them.

Thanks for all the help though folks. I’ve got to get some rest. I’ll resume trying to get 4 good tumblers to a future customer tomorrow.

Good Luck to all you Chiefs and Eagles fans…

I had posted a question here, about lines in my engravings… Worked it out with Speed/Pwr settings.

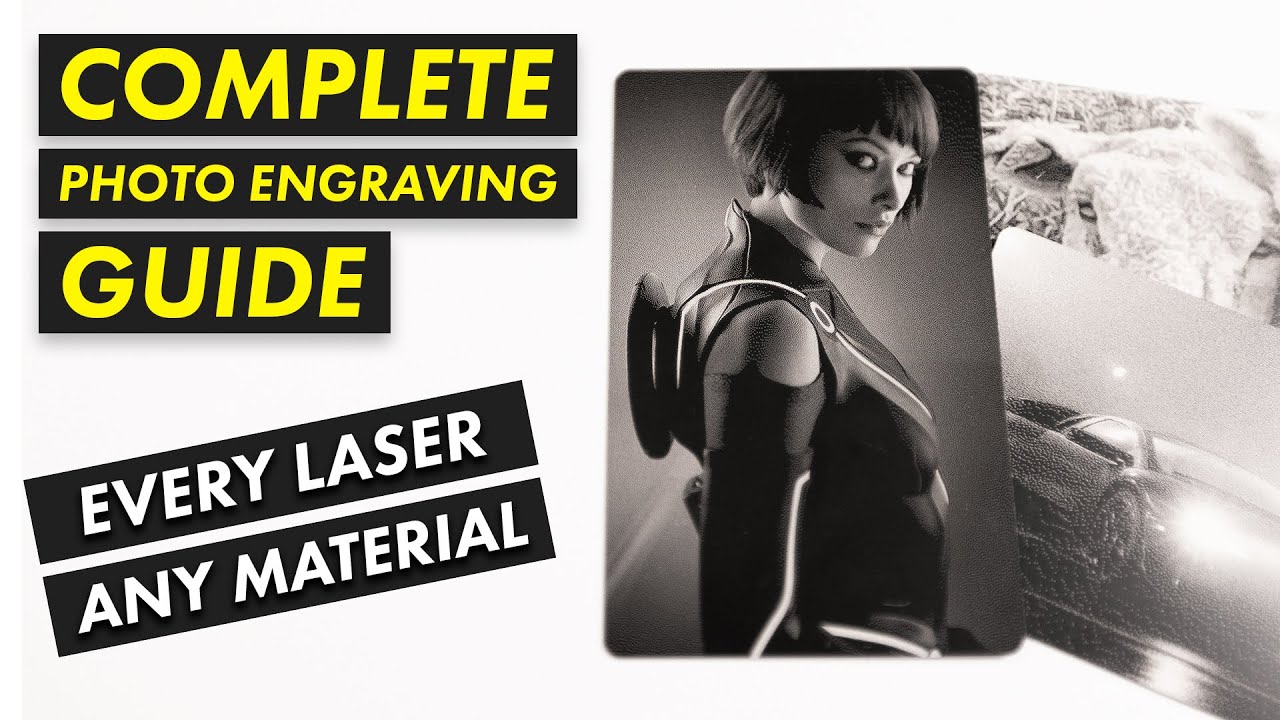

If you haven’t, you should watch this video. Very clear explanation of dpi/lpi and how it effects the finished product.

The best size dot I can get is about 0.1mm with a 2" lens. It’s even larger being de-focused. If you are trying to do 0.03, and your dot size is 0.1, then you are covering the same area you lased as it will be three passes to cover 0.09mm… Which is still less than the dot size…

The video is about photo engraving but the concept of dpi/lpi is the same as it pertains to any job/laser or material.

Good luck

![]()

Thanks J

I’ll take a peek at it. Not really interested in photo engraving. Just commercial work for tourist traps.

I did finally find my magic number. Speed / Pwr numbers for this Orange Tumbler. From what I understand all the colors engrave a bit different based on the color? I did black with no problem.

Of course I’ve been struggling for 2 days getting the damn text to be somewhere close, and it is now. No perfect, but close enough. I would like for it to be right though.

This was done at 50/28. When I was doing 50/35’sh I was getting those lines. Of course this is a tight crop of this square, but no lines. Just looking at it in the hand it looks fine.

https://drive.google.com/file/d/1kIpcjP9fYN8Riq4elcDukXT8EEvpeoO4/view?usp=sharing

One thing that caught me by surprise, is when I type the text, and rotate 90 degrees, is squashes the text…

I’m watching the vid now.

Hey Jack.

With regard to Line Per Interval. When you engrave Powder Coated Tumbs… Where are you at on that? Right now I’m using 0.300 which equates out to around 846. I’m finding out now that this all has to be tied together.

Steps Per Rotation

Power

Speed

Focusing

etc…

I’m trying to get 1 working file with a boundry box to place text into, per color tumbler I’m working with. My black one worked out a whole lot easier than my orange one.

Have you found that different colors engrave differently, or is it just me trying to find a corner in a round room?

Super Bowl Time. I mean rest time. Been a rough weekend.

This is actually 84.6dpi, I assume you mean 0.03 …

This is exactly why I posted the video you’re not interested in. It describes how to figure what dpi/lpi works the best for your material.

I doubt you can make a dot less than the standard lens, which is about 0.1mm… If you want to make three passes over the same area, I guess you’d use that… 0.03. Three passes will only move the beam over 0.09mm, less than your dot size.

I’m using a 2" lens, the best dot I can make is about 0.1mm or 254dpi. That’s what I scan my mugs at… It’s also what I use on stainless mugs that I coat with LBT100 and lase onto the mug.

I haven’t noticed a difference with colors, I think it’s more critical for diode lasers because of their frequency.

This mug is done with a compound lens and the it’s 0.05mm or 508dpi. I can make that size of dot…

Do us both a favor and watch the video, it will answer questions you didn’t know you had… and clarify why the dpi is so critical.

![]()

Thanks. I did watch it. What i meant was i wasn’t interested in engraving photos, but it’s all relative. Yeah. 0.0300… i think. I just have to put the time in on the learning curve.

So you use 0.1mm or 254dpi, instead of like 0.0300, 0.0400, etc… I’ve got 4 practice tumblers to use now. I’ll try that 0.100 and see how that rolls. I’ve never had to use this while cutting flat material, so I’m oblivious to using it. I kind of know what it’s doing, but I want to try your setting as well.

I ran across this at work this a.m.

Lightburn Engraving Interval Test - O2 Creative(AKA%20DPI,dot%20size%20of%20your%20laser.

Thankx

When I looked in my library, I have 250mm/s@70% and either 0.1mm for a standard lens or 0.05mm for the compound.

So I’m running 5 times faster at twice the power that you are… this is in the ballpark of 125mm/s@35% Which is 2.5 times the speed you’re running… My machine measures 44W with a Mahoney watt meter.

Is your machine properly aligned and clean?

![]()

Properly aligned? Not sure what that references. Sorry.

It’s level, and properly focused with the tool they provided me. I’m running a Monport 50w with a 2" in lens. I’m going to play with that line interval today, since I got my customer samples done over this really long weekend.

Temp broke last night, so I’m thinking a bit more clearly now… LOL

Here is a video on proper alignment.

Keep what Russ says in mind, as it will be the biggest burr in you saddle… Especially when something starts to go south on you.

Since Monoport has a bunch of 50W lasers, I have assume it’s much like my China Blue. There was no way this would put out 50W as the tube is only 880mm in length… Have you measured yours?

Does any of this make sense?

![]()

No, I’ve never had a need to measure my tube, and yes, I believe the same company that built OmTech Built mine ![]()

Especially when I bought that piece of crap rotary from monport, and saw another identical to it with no logo on it.

That link took me to OmTech’s website.

This is what I have.

Monport 55W (16" x 24") CO2 Laser Engraver & Cutter