I have that video of yours on a loop ![]()

if you don’t mind where are you purchasing this from. I’m not in the market just yet but feel like I need to learn as much as possible for when the time comes. seems like I’m always finding a new company

Hi James.

I feel comfortable with dealing with BWM. Of course they’re out of China, but have a warehouse in the US in Cali.

The contact I’ve been communicating with is Emily Zhao (Emily Bwmtech). I found her on one of two FB Market Place. She seems very responsive to questions on FB. I have probably asked her 1/2 dozen questions, there, along with these good folks on LB Forum.

I owe a lot to the folks here on the forum. Not sure where I’d be without them. Probably laying in a fetal position in my shop.

I don’t have a good taste in my mouth with Monport, and am so-so with OMtech. I have a Monport 60w CO2, but their support sucks.

That’s about all the light I can shed on the subject. This will be my first Fiber.

This is their site… http://www.bwmtech.cn/?fbclid=IwAR2aBjSVmcExiKf0kHFjSYz41OTRDDe1n8vMizYInNhmS-auQmkJbOuyVEo

I have no complaints with Omtech. One of the reasons I settled in on them is I bought it straight from Amazon. I know I’ll get the product and they’ll force them to support it. I had a bad control panel on my CO2 and they shipped me a new one with no drama. The fiber took 5 days to arrive. Worked straight out of the box, though I’m still in the learning curve stage!!

You’re spot on about the forum. Great people here willing to help. They’ve helped me a LOT!!

yes i bought my current longer ray’s from amazon for the very same reason. just like to know who is selling what and the different name brand i know most are all started in the same factories in china but many upgrade and QC here before hand so knowing a name helps in the choice and if amazon is a possible choice to go through i will always take that choice for security.

I’m the proud owner of a 50w JPT Fiber. Be here in around 10 days.

Tick-Tock

Better start reading and watching videos on it… as soon as it arrives, you will already be behind in the learning curve ![]()

I think you’ll be happy with it… have fun

We demand you post some photos of your fiber work ![]()

![]()

Helloooooooo Mista Jack

That’s all I’ve been doing for 2 weeks. I’ve got several web pages bookmarked already for referral.

Watching this, watching that. All related to FIBER.

Trust me. You will see some work. My first project is to run 20 oz tumblers in a jig. That’s a must.

![]()

I’m trying to make a dent in this 1500 pc order on my coasters. I have jig setup to accommodate 4 of them. Still takes 8 minutes for all 4. 400mm/15/0.07LPI

I tried all 3 different fill styles with regard to grouping. 8 minutes is the best I can get. If I speed her up, the text on them start looking double’sh.

Right now, the most efficient one is FILL all groups together.

Thanks for all the help!

It depends on material and cork is a little odd, but there’s no benefit from a dpi/lpi of 0.05mm to 0.10mm… yet it takes half the time… at least in one direction.

I have to have a compound lens in the machine to achieve 0.05mm, my original lens did well to get to 0.10mm for scanning…

Might try a coaster at 0.10mm and see if you get reasonable results to increase the speed of each batch.

My only thought of speeding it up that hasn’t been discussed… maybe you already did this…

I’m glad we agree, you are already behind ![]()

![]()

Can someone share a site, that explains Frequency when it comes to fiber lasers that an old redneck boy can understand. I got power / speed, but I think I’m going to need to understand where frequency rolls into the equation?

You need to understand how a fiber laser works to understand how the frequency applies…

Fiber lasers pump up the fibers energy levels and another led triggers the discharge or the actual pulse…

The higher the frequency the shorter time the fiber can be pumped up resulting in more pulses but lower power/pulse.

Figuring out about how much power/speed/frequency or pulse rate needed are basically figuring out how many pulses/mm and how long the pulse duration exists heating the metal to the desired temperature. This applied to the type of metal and it’s thickness you’re in the ball park…

This, of course, changes when you change lenses, seems like a lot more than it does on the co2 machine when I change lenses.

It can rather confusing and I’m not sure I have a good handle on it myself…

You can probably find videos about what frequency changes effect, but it’s pretty much pulses/mm and pulse duration…

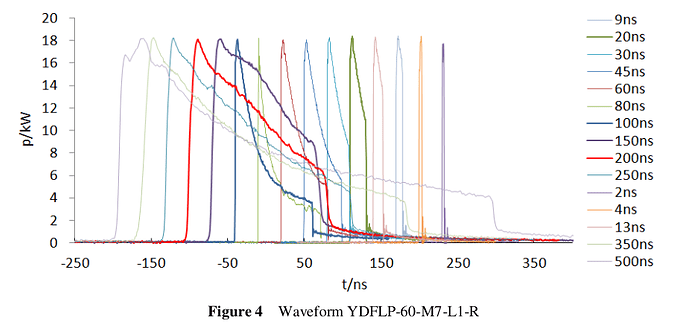

Here are the pulse width/power curve for different q-pulse widths from my M60 JPT M7 MOPA manual…

Here’s a spread sheet that gives you pulses/mm… it’s set up for my model of machine, but it gives you an idea… don’t know if model is really applicable, at least it’s power rating.

![]()