I was running trails in grayscale image mode…it started well but when it was around 20% complete my laser went haywire and started cutting lines well away from the intended cut settings…This is first time I’m experiencing something like this …could anyone give me a plausible explanation for this ?

Looks to me the top section is tapered down on the right.

I doubt software.

Check your rails guides belts and all for trash in them. Is there something stored nesr the rail?

There’s no trash in the system…but the thing to note is…when i fire a pulse and drag it vertically…the line is defined but it’s not the case when the drag that pulse horizontally… there’s gaps and …beam width isn’t constant

Try moving it vertically where the line is missing on the X axis, see if it fires all the way up.

Anyway, looks like an alignment issue and possible mirror or lens is dirty? If alighment is out it could be meaning the laser is moving across the lens as it gets further away from the souce and going through some dirt on the lens it could cause it…just ideas doesn’t explain the initial problem though, no idea why it would do that sorry

The first image was chaos. The second looks decent. I think the empty spots are just wood grain issues.

If it is ran at low power… And higher speed… It may not show.

I dont see the halo that is associated with a unaligned laser. Mayne it needs to be more still for that.

Go to each corner and pulse laser at 15%

Should be a clean dot. If it is out… It will have a dot and a cescent shape near it.

I’ll try that and revert back

dots on the corners are just fine…no crescent shape created by the pulse

Have you tried the same image again since?

It looks like something is loose or dirty.

What speed and power is that ran at?

You can see the image is in the lines. Just the lines are not in correct spot. They apear to even be tilted.

sp-180

max.power-17

grayscale image mode

700 dpi

these were the settings I used

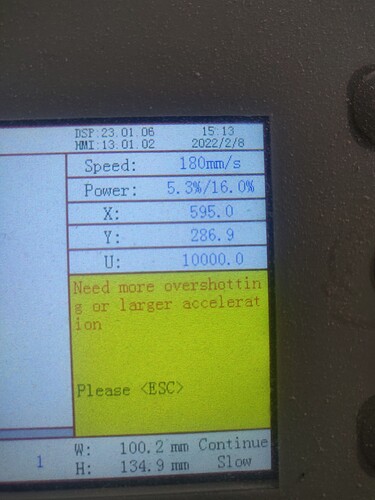

please have a look at this image too and share your thoughts

controller is KT 332N

Try moving the image more towards center of the work area or change the direction of the scan to 90.

I dont like running the scan on the y axis… But its what i have to do.

Ruida words it different. But i read it to be that the controller sees it needs more space for it to overscan the item printed.

Feels like a low number to me. But might be machine difference.

I get that message if I’m to close to the edge of the travel area, the head has to have space to slow down to a stop and reverse direction after the burn.

Steve

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.