If I calibrate my steps for a certain size my cut will come out perfectly. If I calibrate my steps for a 2" square it cuts perfect. But if I cut something that’s 22" it comes out around 22.25. but if I calibrate steps to match the 22" and cut something small the small cut is off. I hope this makes sense. I’m just trying to figure out why it won’t cut consistently. I’ve had a laser manufacturing company tell me it was laser alignment. And a buddy told me it was due to the machine microstepping and not being geared. I’m running the red and black 60w machine. Anybody have any input on this?

If my math is correct and I read what you said correctly if you calibrate for 2" and run a job 22" it’s off by .25" which comes out to be about .011" per inch error. That’s not very much for something small like a 2" job but when you add them all up in a 22" job it can add up to quite a lot. I’d lean toward the stepping calibration. On my cnc router using Mach 3, I calibrate using a long distance on my work surface just because the longer the length of the calibration the more obvious the error is. So once I’ve calibrated at say 30" it’s very accurate at 1"

When you calibrate, are you accounting for the kerf produced by the beam?

The cuts have thickness - If you cut out a square, and measure it, it’ll be off by the size of the beam. If you measure the size of the shape that was cut out, then measure the size of the hole, and average the two, you’ll get an accurate number.

I’m glad you posted to this topic. I was just thinking last night it would be really nice to have Lightburn have a selection of cutting inside or outside a profile & kerf or tool thickness option like some programs used for CNC modeling. Sometimes the piece being made is on the inside and other times it’s on the outside. In order to get a dimensionally accurate piece for each one would need to adjust their steps each time or adjust the size of the model to accommodate for the kerf. Is this something Lightburn has thought about implementing or something already there I’ve overlooked?

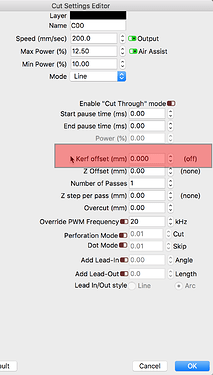

Kerf offset: Allows you to shift the cut inward or outward from a closed shape to compensate for the diameter of the beam. This is useful when making parts like inlays or finger joins.

Thanks Rick, That’s exactly what I was asking about. Looked at that screen hundreds of times and never even seen that option.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.