I have just upgraded to an 810 x 460mm 20 watt diode laser. I have had all my previous lasers adjacent to a window with three exhaust fans and a 4th blowing across the work. It is very effective. In addition my work space is limited. The problem is that the new laser is set up with the 810 on the X axis and the most functional way to set up the machine is with the “front” against the wall and the back open for work placement, etc. The laser homes on front left but I will be using the rear left side and my origin for all my smaller products The problem is, my work space on Lightburn is, of course, reversed and counter intuitive. Is there any way to rotate the grid 180 degrees so that the left rear becomes 0,0 even though the laser will initially home on 460,0? I have watched dozens of set up videos, read dozens of Lighburn set up articles, and have fond nothing.

Thanks!

Bob

I suspect you could get this to work assuming you have standard GRBL.

In basic:

- Reverse direction of X and Y axes

- Reverse homing direction to accommodate reversing of axes

- Create work offset to reposition origin

The Laser has standard Grbl but I don’t I have the various locations for inverts but not sure that is what you are referring to…

I was thinking about using the offset for origin but hadn’t gotten that far .

Thanks!

Bob

Here’s a reference to GRBL configuration values:

Specifically relevant here:

$3 – Direction port invert, mask

$23 - Homing dir invert, mask

Work offset will be done using G10 L2 P1 X?Y? with the XY values dependent on the work offset desired.

All these values and setting are visible and changeable through Lightburn, but it still doesn’t seem to accomplish what I need… I will do some more testing later…

Thanks!

Bob

In what way? Unless I’ve misunderstood your current setup and your desired setup my approach should work.

Can you create a diagram of old vs new setup? I might have missed something.

Also, can you run these commands one at a time in Console and return output? Please have your machine working in its original state before doing so.

$H

$I

$$

$#

?

Can he just swap the x/y motor drivers or cables along with the limit switches… The front of the machine won’t face him, but it will be oriented correctly…???

![]()

That’s my vote, too: make the hardware match the software’s expectations and move on.

I don’t see how that would work. OP states 810 is on the X axis. And wants the front of the laser against the wall. He’s looking to change orientation of the laser by 180 degrees, not 90 degrees. Unless I’ve misunderstood something.

I was under the impression that he explicitly wanted homing out of the way from where he’s working. Again, unless I’m misunderstanding something.

I thought that was his hopeful list… I was trying to get him operating, quickly…

![]()

Got it. I didn’t realize you were offering an alternative approach. Although I don’t think it would be any faster given that theoretically this should be 3 commands to the controller and no fussing with the hardware.

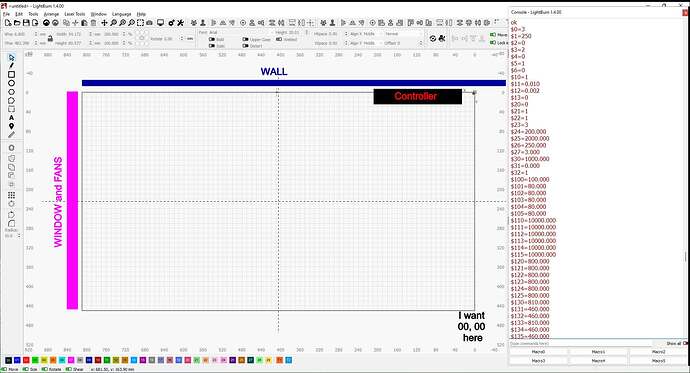

This is the current annotated screen shot… I looked at moving the controller, not possible because the limit switches are on the controller. All I need is the origin and associated values shifted as indicated in the pic. Homing can remain as is.

Thanks!

Bob

I want to keep the controller near my side of the workspace and closer to the PC, power and compressor. That is why I have it facing the wall (See Screen shot)

Thanks!

Bob

He’s looking to change orientation of the laser by 180 degrees, not 90 degrees.

Exactly!

Can you run those commands listed in my earlier post and return the full text output from console?

Also, can you confirm that the laser now homes to the top-right in your diagram?

Assuming that your machine does home to top-right in the diagram go through these steps:

- Run these commands in Console:

$3=1

$23=0

G10 L2 P1 X0Y-460

$10=0

- In Edit->Device Settings change the Origin position to bottom-right

- Test homing by shutting off the machine, moving the laser module to the middle of the frame, then turn on. Be prepared to shut-off the machine or manually trigger the homing switches. Does it home toward top-right?

- Test jogging controls. If the homing has worked properly, test all jogging directions. Do they work correctly in the direction expected? If homing has worked correctly manually trigger limit switches and test jogging controls.

- Test position after homing by running in Console:

$H

$#

?

Can you return results please?

$H

$#

?

<Idle|WPos:-0.012,420.477,0.000|FS:0,0|Pn:Z0|WCO:0.000,-460.000,0.000>

ok

[G54:0.000,-460.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

After making the above changes the laser just generates hard limit errors

ALARM:1

Hard limit triggered. Machine position is likely lost due to sudden and immediate halt. Re-homing is highly recommended.

On or near line 4:

Thanks,

Bob

- Does your laser have a Z axis and switch? If so, wasn’t expecting that.

- Also, did you run those 3 commands in series one after another? The position is not exactly what I expected.

- Can you provide answers to questions 3 and 4 in the previous post as well?

- Confirm that you changed origin in Edit->Device Settings

Right now the laser is totally screwed up.

It will only vibrate and produces this error…

ALARM:3

Reset while in motion. Grbl cannot guarantee position. Lost steps are likely. Re-homing is highly recommended.

[MSG:Program End]

ok

V

When does it do this?

With power off, move laser to middle of frame. Turn on. I assume the machine automatically homes. What happens? Please be as descriptive as possible.