The ‘general term’ of ‘tumblers’ covers tons of different materials. It might help if you were more specific on the type. Such as a link. The ‘sublimation’ can be applied to numerous materials.

Without any details, we can’t really help much… but here are a few basics…

…

If they are glass or porcelain, where I see most of the ‘sublimation’ graphics, then you can damage them with a laser. Meaning you can ‘engrave’ them but in detail it is shattering the glass, which limits resolution. When I do this, I rub them with steel wool to remove any ‘shards’ of glass that haven’t but will come off. Ending up in the users fingers or elsewhere.

There is also the ‘Norton tile’ method that has lots of threads here. This uses a paint that contains titanium oxide that turns black when lased… Then you have to get the cup/tile cleaned up from excess paint.

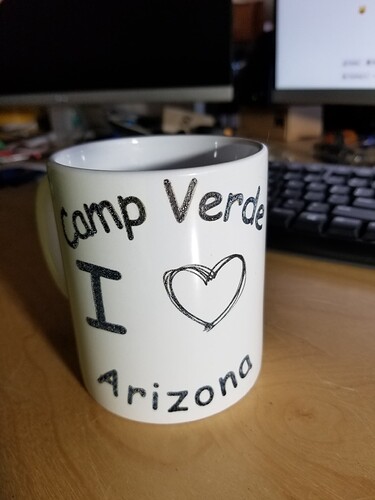

This is using the Norton method, but it’s early and I found it a drag cleaning off the paint.

If they are stainless or metal, you probably have to use one of the coatings that will molecularly bond with the metal when lased. Most metals have a high reflectivity rate, over 99% and do not lase well since the power cannot be applied to the molecular structure and/or the metal itself is a good ‘heat’ sink that removes heat from where the laser is working.

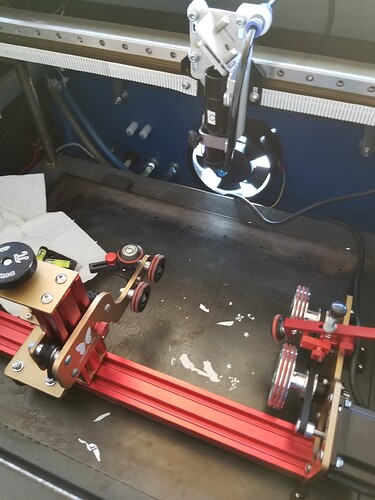

This is using LBT100 spray on a stainless steel tumbler.

What kind of rotary do you have? I have a PiBurn…

Take care…

:smiley_cat