I have done some ceramic tile with my 7 watt Jan and used the paint method and it work pretty well.

If you want to try @Bulldog method you need to dial you laser under 1 watt. His best work is at 0.75 watts… Rustoleum white as well of course

Cheers

Sasquatch

@Sasquatch

I’m going to the hardware today to pick up some paint.

Question, Have you used this process on corian?

No but it’s sounds intriguing. I would love to see what you come up with. Have you seen @Bulldog process and end results?

Cheers

Sasquatch

Actually @Sasquatch

My diode is 2.5 watt Eleksmaker and I use 80-85% power when doing Tiles

I did this of my Grand daughter on a Corain Plate …using the Norton White tile method

Wife was not too happy with me…lol

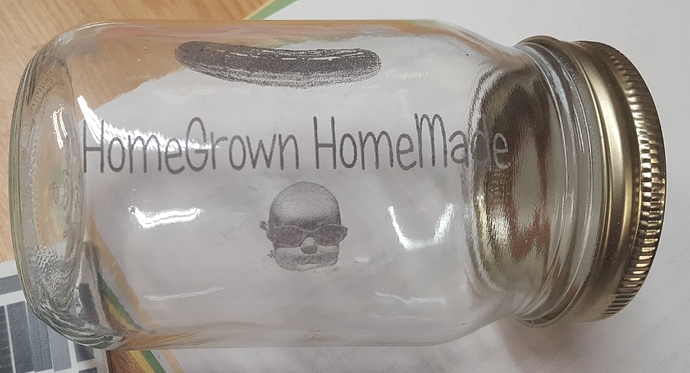

Also pickle Jar

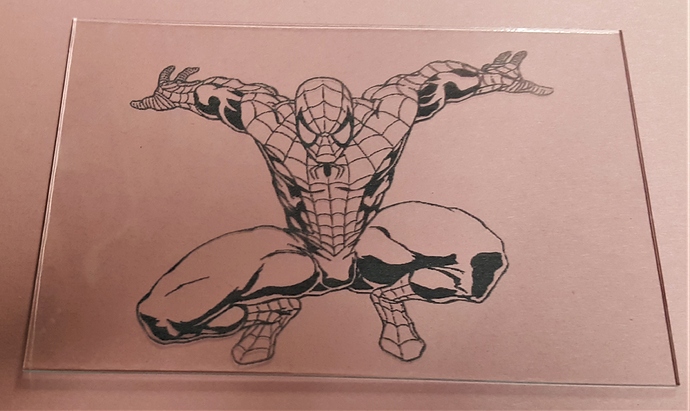

Glass

and a LightBulb…

Beautiful… thank you for the correction. Nevertheless the main point is that you are 2.5 watts and below. Which allows you to be low and slow burn and that is key in your amazing results.

Cheers and thank you for sharing that the process is possible on additional substrates .

Sasquatch

Sorry, I just got back into the shop.

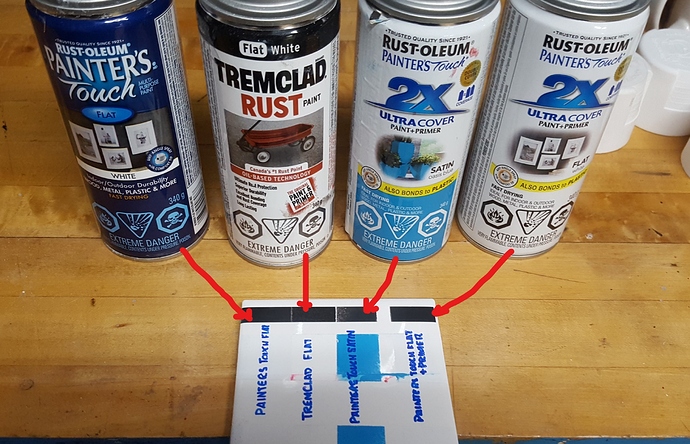

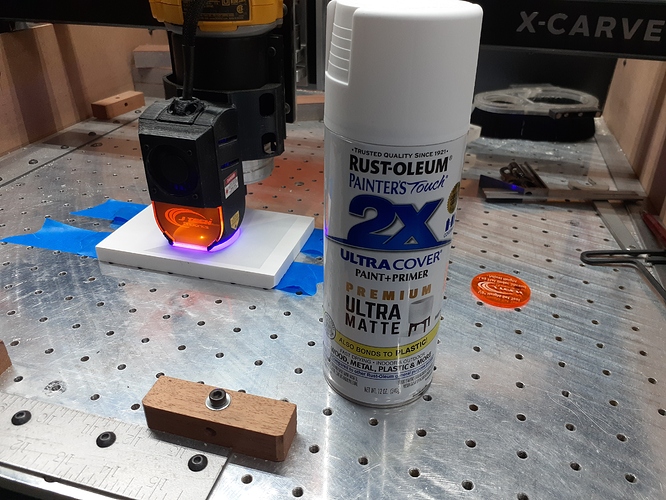

So, I bought this paint.

Sprayed it on my piece of corian.

As you suggested I set my power to 10% (which is .7 watt) @ 60 IPM.

There was absolutely nothing showing up on the cut.

So I stopped the program and bumped the wattage up to 30% (2.7 watts)

Now I can just barley see the image.(you have to look really hard)

This is my image. (good luck trying to find it)

Try printing a test pattern at different power levels and different speeds to dial in your burn.

Also are you printing a color photo or have you converted to BW and the further processed it in Lightburn to adjust the sharpness and then selected the dither mode?

Sas

I brought in the color photo just as you see it.

Is that a mistake?

Here is a good read from a past post

Try using dither modes it will give you a better image that the laser can burn

Cheers

Sasquatch

I read that post and don’t quite get it.

Because I’m kind of an impatient person, I am now doing the following.

While I know this will not be a true representative (due to compounding effect) of the end result, I started out at 10%,then re-ran it at 30%, now i’m running it at 80% (5.6 watts)

I don’t think corian likes me (my laser)

Or maybe I just don’t know what I’m doing yet.

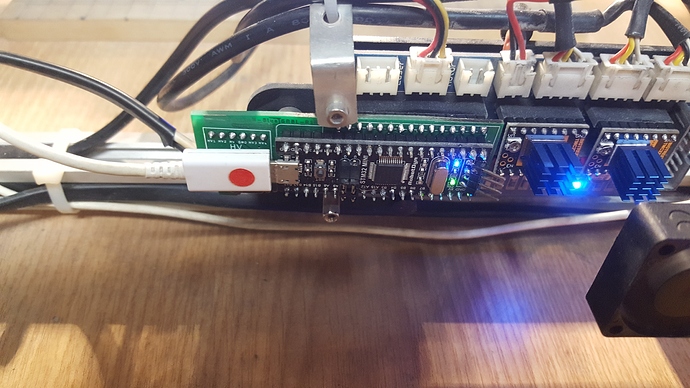

@Sasquatch…that problem was resolved when Timothy Rothman…designed and Built me a 32 bit nano that was plug and play…

@JVL…I always convert to B/W resize and set DPI (339 for my laser) in paintShop Pro

import int LightBurn

Under shape properties adjust gamma…contrast etc…untill the the image has the “Laser Look”

then Jarvis or Stucki dither

Two main points that will make or break you

1/only one thin even coat of paint…MUST be thoroughly dry

2/ the most critical part your beam MUST be pinpoint focused

also if you use air assist it will not allow paint fusion process to happen

I use 1200 mm/min…(47 inch/min).any faster than that I start to get greys

Here is a 32 bit plug and play board that is available and has great customer service! I have followed his progress from the beginning. I know it says K40 but you can use it on any laser.

https://awesome.tech/mini-gerbil-specifications/

I have 2 miniGerbils, a pre production, and a release board. They are a solid little controller.

approx $80 us …no shipping to Canada yet…pretty much what i have,except I still use the Mana SE controller

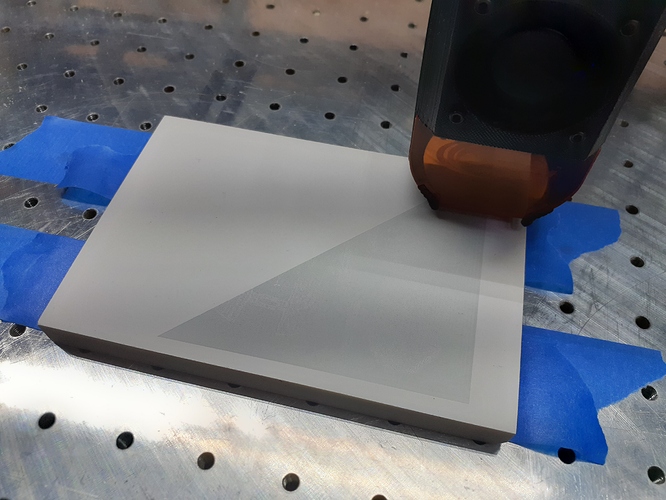

So here is my latest results.

Painted the corian with white paint.

45 IPM 10% power (.7 watt)

I stopped the cut because there was simply nothing happening.

I increased the power to 50% (3.5 watts)

The only thing that I did different that bulldog is I used the grey scale setting instead of the Jarvis.

I did this only because the Jarvis preview is absolutely horrible

I don’t know if that was my mistake or not.

This is the result.

After wiping off the dust, this is the end result.

20200420_182743|666x500

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.