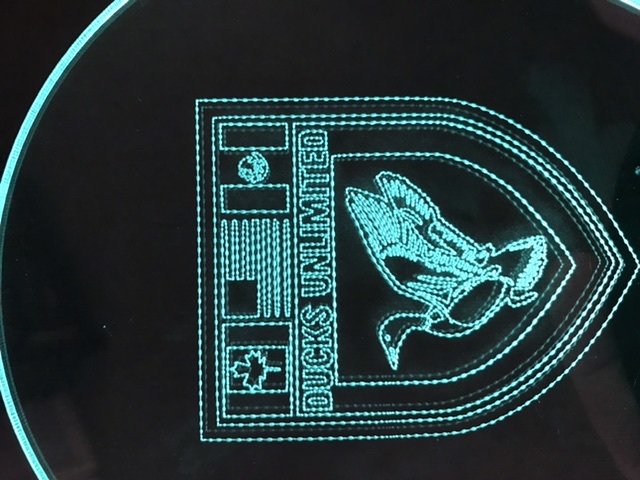

So I’m new to using laser cutters, I bought an orionmotortech 50w co2 laser off eBay and started using it last week. I noticed the laser doesn’t seem to be cutting solid lines, instead it looks dotted. Any suggestions? I know the perforated setting is not on.

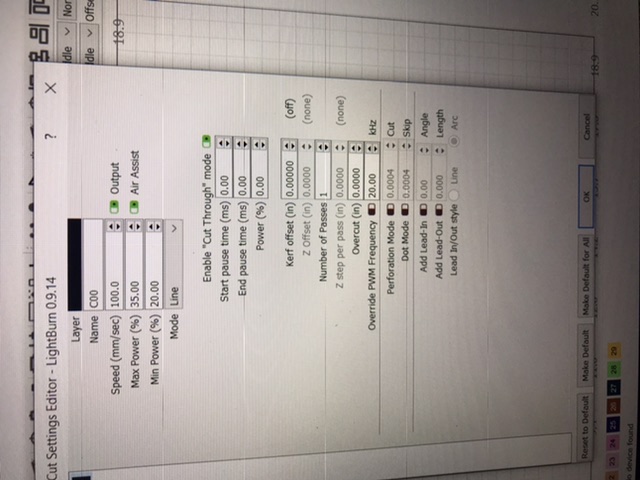

Can you post a screen shot of the cut settings used? That doesn’t look like a setting issue - all the perforation styles in LightBurn would produce even spacing, and these are varying with the speed of the laser head - they get closer together at the corners. To me that suggests an issue with your power supply, but there is one setting (PWM freq override) that could do this, so I’d like to double check.

I assume these are the settings.

Yes, but I don’t see anything strange there. Turn off ‘Cut through mode’, because you aren’t actually using it (the delay and power settings would need non-zero values in them), but it’s incredibly unlikely that would be it.

My best suggestion would be to install RDWorks and run a test of a simple square on both programs, using the same settings. If they come out the same, the problem is the hardware, likely the power supply for the tube, or possibly the configuration, but I’ll say this is the first I’ve ever seen this.

I ran a test with RDworks and lightburn and got the same exact thing on both. Same settings feeds and power etc. I guess I’ll test the power supply to see what is going on there.

So I test the power supply and it seems to be functioning as it should. I ran it with the test button and it’s firing. Any suggestions about the configuration?

Go to Edit > Machine Settings and save the file to disk. Email that to support at lightburnsoftware dot com with a link to this thread and I can have a look.

You won’t be able to test the PSU firing operation unless you have an oscilloscope.

I would go over your machine thoroughly with a multimeter and make sure you have a solid earth everywhere you should - PSU cases, ground points on PCBs, the controller, lights, and get a figure as close to 0.001ohm as you can - tighten screws, scrape paint to get a good connection, check eery cable connection point, etc. and check the chassis ground at many points against the centre ground pin of the power cord.

Extremely safe to do, as the cord has to be unplugged from the power to test it ![]()

Then run the machine with the back cover raised and check that there is no arcing coming from the anode (+) to the chassis or other component. dim the lights, if possible.

This is a typical problem with poor electrical QC.

Orion are a wholesaler, not a manufacturer - they probably never see the machine that they sell you. Let them know if you find anything and they’ll run it up to their supplier, which helps us all ![]()

I haven’t done a full ground to it yet. When I was watching it cut I didn’t see any arcing or anything Of that nature to or from the tube or in it. I will run a real ground to see if that helps.

Don’t use the chassis ground post - that’s for countries with two-pole cabling. You should use the power cable ground, to keep everything at the same potential.

And unless you go through and check all the grounds through the machine, you won’t know what state it’s in.

You can use the chassis ground post for earthing your water receptacle. It stops the water building static and causing issues. I just drop a piece of wire in the water. Not needed on chillers, as they nearly always use grounded three-pole plugs.

I did check the regular cable ground. Everything is good and no resistance. My outlets are good too, I’m thinking it has to be a power supply issue. That’s why it looks like it’s pulsing.

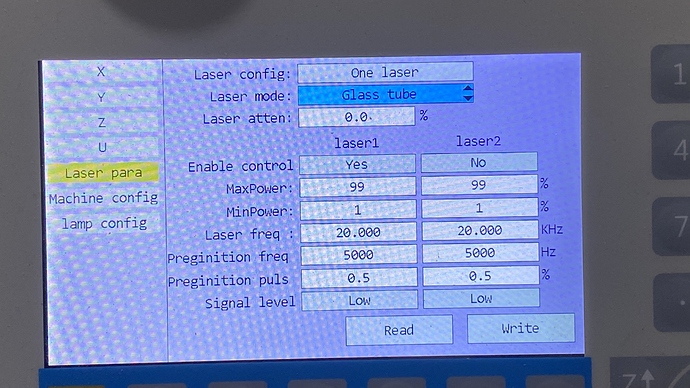

On the Ruida Controller, check your laser parameter settings. They’re within the manufacturer settings.

-

Laser Type (Mode) is set correctly: Glass Tube, RF laser (no pre-ignition pulse), or RF laser (pre-ignition pulse)

-

Laser Frequency

-

Pre-ignition Frequency

-

Pre-ignition Pulse

Here is what I have on my 6445:

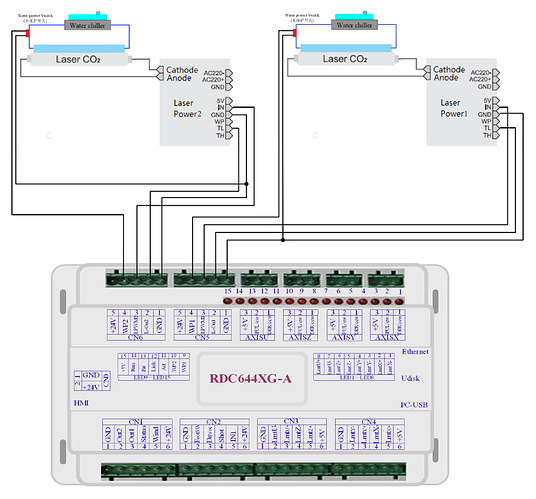

Also, inspect and verify the wiring on the controller is appropriate for your tube type (assuming you have a glass tube) and correct:

Is this how the machine has operated since you started using it? Has it ever NOT had this problem? Who is the manufacturer of your glass tube. Who is the manufacturer of your laser PSU?

It has been doing this since the first test cut/etch. No changes were made either. This is brand new to me I got it set up last week and started using it this past weekend.

Did you check the Laser Parameters as suggested? To see these, you will need to enter into the manufacturer settings on the controller. The password is most likely RD8888. No mention of this in your response. Tube manufacturer? Laser PSU manufacturer?

I did check the laser parameters and they are perfect compared to what you sent. The tube is glass and the I’m not sure who the manufacturer of the tube is because it is covered up by the hold down.

Do you mind if I inspect your design? If you don’t mind, load it so I can inspect it. We also do embroidery and almost looks like the design was digitized for embroidery.

I was able to get it resolved, it was the power supply and now everything works perfect.

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.