I have the exact same tube ![]()

They usually specify both maximum and maximum working current. Maximum current is the don’t exceed this. The maximum working current is the where it’s designed to run for the user.

If you run 80% of that, it’s 16mA, and I run that as a general maximum. I push it up to 18mA if I want to cut something heavy like 1/4" (>6mm) acrylic. Note this bump is only to 90% of the working current or where it is designed to work.

If I felt the need, I won’t have a problem running 20mA, that is my maximum setting of the lps.

If I needed this kind of power very often, I’d have purchased a longer, more powerful tube.

It should be insulated, this is clearly not. Once hv punches a hole through something, the damage is done and the insulation can no longer be trusted … hv will reach out and touch something if given the chance… and it’s more than likely it will reach out and touch you…

@bernd.dk suggestion will work fine… I have used these HV connectors from Amazon a number of times. At least Amazon says this is what I ordered. Measure the size of your hv wire… There’s at least two sizes…

My hv meter uses a pair of them in the anode circuit in the electronics cabinet and another set for the tube connection up stream, they are easy to use…

Another option is a high voltage tape that bonds to itself and blocks a high voltage potential… These are specifically formulated types of tape, not usually found locally. This particular tape is rated at 69kV. I’ve seen this used successfully for these types of issues.

For your application I’d try the tape… ensure you read and understand how to use it properly.

Trust me, you don’t want a surprising and intimate relationship with your lps.

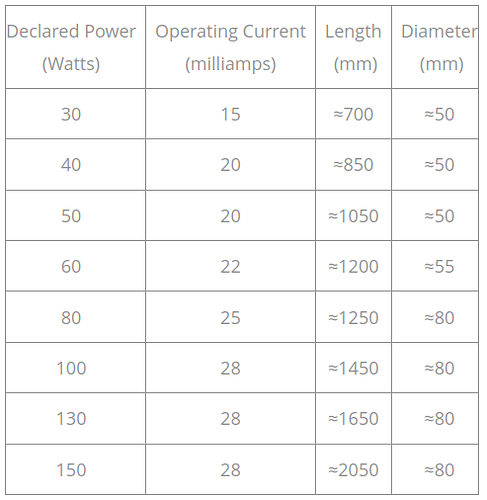

I’ve followed this chart for tube current for a couple of years and it’s always seems to be accurate … So, I’d suspect @bernd.dk is under utilizing his tube … ![]()

![]()