I need help, my laser just started jumping mid job. I had just finished running 3 other jobs with now issues. Started this one and bam it went nuts. Anyone have any idea? Thanks.

Ethernet or USB? If it’s connected by WiFi, that can be an issue.

I’d check the rails to make sure there are no sticky spots - it doesn’t look like you’re running fume extraction, so if the rails or bearings get gummy from the smoke it’ll cause problems like that.

I had cut the blower and air off, then turned it on. I had ran the same job 3 times already, had just swapped leatherette color to run again and it started. USB, I always send file to laser then run from there.

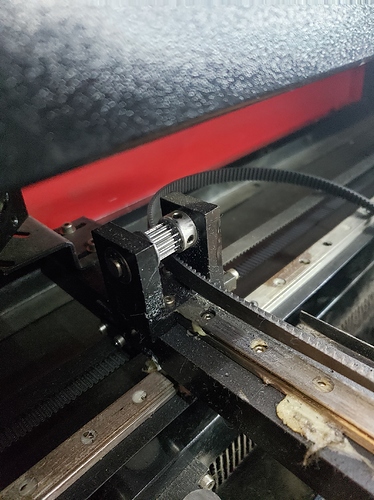

I’ve figured out it’s this roller, anyone know where I can get a replacement? Is there anything I can spray on it, when I roll with my figure it catches.

Sounds like you need to replace the bearings in the roller. Spraying something on it will most likely not improve things. You can try dissasemmbling the assembly and cleaning and re-lubricating it, but my gut instinct is that the bearing(s) has gone bad.

That’s what I figured, where do I buy a replacement and how do I know which one I need?

I have not had to look for this specific bearing but have found this helpful in the past:

The quickest way to determine which bearing you require is using the bearings reference number.

Most bearings have their reference numbers engraved on the bearings themselves, but these often rub off over time and so it may be necessary to measure the bearing yourself, as described below.

https://www.bearingboys.co.uk/Measuring-Bearings-15-a

Thanks, was hoping I could just buy the whole thing and slip in a new roller.

Maybe an additional post to the General Laser section might get you some resources from the broader community.

You probably don’t need the pinion, but just new bearings - if the pinion itself is in good condition, you should be able to measure the bearings with calipers and replace them with the same inner diameter, outer diameter, and width.

So there are bearings inside of that pinion? Do you know of a video of showing how to replace?

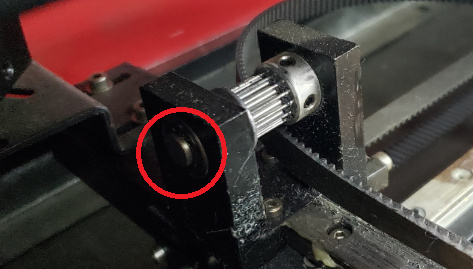

They aren’t inside the pinion - they’re here, on either side, in the aluminum blocks:

There are little hex-nut set screws holding the pinion on a shaft that runs through them. Loosen those and you should be able to get everything out, though I’ve never done it on one of these machines.

Wow. When was the last time you did any cleaning + lubrication preventative maintenance on that machine? I would not be surprised if you had multiple issues lurking ready to pop up. Those rails are really rusty. Your exhaust grills are getting so gunked up they have to be restricting your airflow/exhaust efficiency . Have you ever taken the hoses off of your fan and checked the fan for build-up on the finger guard/grill and internal blades? I would not be surprised if there is a huge amount of build up on those at this point. As the old advertisement said, “Pay me now or pay me a lot more later.”

Hasn’t been that long ago that I cleaned the air removal grates off. I do a bunch of leatherette, so it doesn’t take long to get dirty. I’ve never taking the blower apart, but I will this weekend. The rails do need a little cleaning, what showed I spray on them? Doug do you know where I can get a replacement pinion roller?

No, sorry, I do not. Please post back here with the info. if you find a source because someone will need it eventually.

whats happening here is what happened to ours, on the right hand side of the idler it is grinding into the metal bracket, undo the grub screws, hold the shaft where the red circle is , slide the idler towards the red circle while holding the pin, then re-tighten. Should cure the problem.

Also while you are there check the other end of the drive stepper motor to make sure the grub screws are tight in the drive gear, ours didnt even have any (thanks china for your fabulous quality control)

Clean with iso or other solvent - but keep away from any plastic parts unless you know your solvent is safe with that particular plastic.

For lubrication, a dab of lithium grease on a cloth and rubbed the full length of the rails, followed by a program of full-stroke back and forth along both axes should clean it up.

You can use silicone spray, too, if you are sure it won’t affect your plastics, but if you have nylon parts, don’t - it can cause the nylon to swell and eventually become fragile.

I usually give a rub-down with lithium (white) grease every 10 hours operation, or so, depending on what I am cutting. As most of my work is on plywood, it’s not as dirty as plastics and mdf. Leather and other organics are particularly dirty and you should be setting aside time to clean your lenses and mirrors, as well as lubricating.

Your problem is likely caused by a lack of maintenance.

Exactly what happened to mine, I took it all apart and cleaned it, that’s when I noticed the groove. I couldn’t find any bearing local, so I have ordered some. But I just put it back together for the time being until new bearings come.

I will clean it, but the problem isn’t due to poor maintenance.

How often do you clean and lube?

I would love to send you a pulley - I have about (literally) 450 or so - but they’re buried somewhere in a shipping container in a warehouse and I ain’t unloading it all to find one pinion

That looks suspiciously like a GT2 - 3mm belt - common in most small machines, but check.

Any diameter and width that fits the gap will be fine, as it’s acting as an idler, not a pulley. Anywhere that sells 3D printer parts should have them.

Openbuilds definitely will.

Replacing the bearing would be trivial, too. Most bearings have the code stamped on them, but the formula is straightforward - Inside diameter, outside diameter and (occasionally) width.

If I remember correctly (I can’t measure due to aforementioned container issue) they are 625 2RS (5x16x5mm) sealed bearings.

Very readily available.