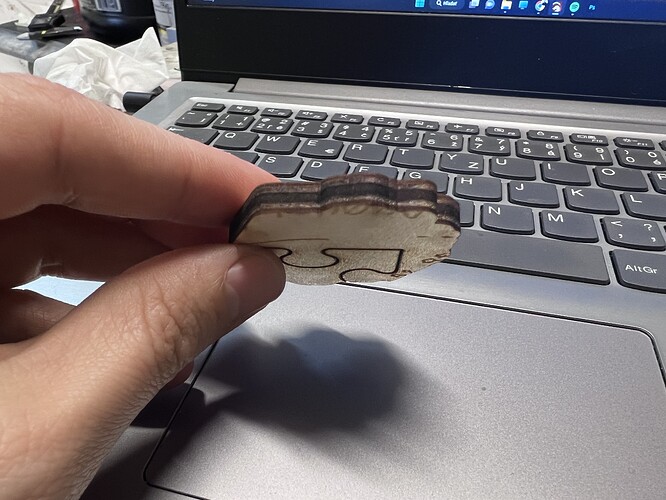

Now there is really no doubt that that tube is quickly on its way to its last journey, I had hoped that it was not so pronounced and that there was some life left… unfortunately.

Could it be that you have driven once with poor cooling or no cooling at all? It is also interesting how much power you have driven that tube with over time.

I hope you get a new tube soon and start your production again.

After all, it was a good day . I achieve good mirror alignment, and the power that I miss yesterday is back . Today I learn how to do it ![]()

And the tube … I don’t know where is that 3000hours lifetime goes ![]() or that quality that EFR declares but I starting to look for replacement , Reci? Stp? Or some other brand ? I have red and black Chinese 700x500 machine .

or that quality that EFR declares but I starting to look for replacement , Reci? Stp? Or some other brand ? I have red and black Chinese 700x500 machine .

Again thanks for tips and advices , I guessing I will be back soon with other problem ![]() I’m in learning mode

I’m in learning mode

On peak summer is in my garage 37 celsius , and after 2 hours and more my water temperature on industrial chiller goes up to 39 celsius im stop working . i have cw3000. over drived was only 1, but it runs only 3-5 seconds at 90% . mostly between 30-45% of max power .

Does this mean that you have limited options to drive your machine until the new tube arrives?, if the quality is ok for what you use, it’s fine.

Mmmm, there are many in Asia who drive between 30 and 40 degrees Celsius, I stick to the 20 degrees.

But the CW3000 is also not the right solution for a CO2 laser machine, in my opinion. An investment in a CW5000 will probably be appropriate.

How many mA does your (milli)ammeter show at 90%?

I’m probably not saying much that hasn’t been said but I also shoot for 19C and use a 5200 compressor style chiller. CW3000 is basically a water pump with a flow alarm. Before I picked up the 5200 I was able to use the 3000 with a radiator and cooler of ice. It went through a lot of ice. I’ve never heard anyone running a CO2 tube up to 40c but you can check with the manufacturer.

I used to run mine at 25C but have found it works better at a lower temperature.

I also think the short tube life of mine had multiple reasons for it’s early demise…

Most of the time it wasn’t being used, in summer, the ambient temperature high could easily have been close to 120F (49C) for many days. If it wasn’t being used it sat at that temperature until it cooled down naturally or I put it into use. Even at night the temperatures can be above 90F at times.

I would run it at 18mA quite a bit (lps current is set to 21mA)… when it started to fail I really abused it… ![]()

I was getting good output, then after a long weekend of three days, it wasn’t working like it was. When I did the m1 test, it was not only out of TEM0 mode, but had moved away from the center of the target… Seemed to happen pretty quickly…

I replaced mine from Cloud Ray with one of these… Russ Sadler recommended, his recommendation always seem pretty solid… I’m sure they make a wide variety of wattage tubes… I didn’t need much power, so I stuck with what I had in there… power wise.

Good luck

![]()

I mean, as long as the temperature is not above a certain limit, and does not fluctuate too much, it is not critical whether it is 18 or 25 degrees Celsius. (too low a temperature can cause condensation problems - is also not good)

Some believe that a CO2 tube must even rise to a certain temperature to run optimally, but I don’t know if that fits.

Another “small” problem in this context is that I am always very nervous about air pockets. Even if my machine and tube are set up correctly, every morning I have very small air bubbles, in total approx. an area of 1-2 mm2, right at the exit. I have tried a lot to avoid it without success. If I do nothing the CW5000 pushes the air out but it takes up to 30 minutes. I squeeze the water hose 2-3 times and everything is fine…My theory is that the small output glass tube is “welded” a little too deep into the Ø50 tube itself and has formed a small obstacle, a pocket, just deep enough to microbubbles can gather here. BUT, as I wrote before, 2-3 times press the hose and there is no problem, I do as naturally as turning on the machine and the other peripherals.

I don’t know what’s going on in there well enough to guess. I do know mine would laser down to about 7% if it was cold enough… Mine is set for 9% in the controller, but I stay away from lower percentage values, such as single digits.

I believe that heat is the biggest culprit, seems to make everything react/die faster, so I have to assume that my idle tube, in the garage at 100+F was not in it’s best interest.

It surprised me that the tube would lase at a lower percentage power when cooler than warmer…

The bubbles should not cling to the side of the tube where you need to remove the heat, that causes the glass to heat unevenly and cause a failure.

I had an additive (propylene glycol) in my coolant that caused a flow of bubbles that made the coolant look almost white… I sent this video and asked Sadler, he advised it was not a problem…

![]()