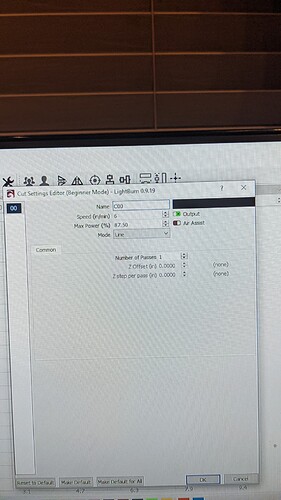

I started this burn and within the first 20 minutes it was clear that it was not going to look good. It was too fast and it wasn’t getting a complete burn.

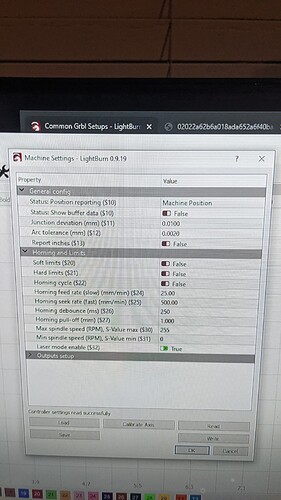

When i type $$ here’s what i get. Does not have $30 $31 $32. running eleksmaker mana se v 3.2 anyone know why?

$132=5000.000 (z max travel, mm)

ok

We have seen this machine ship with an older version of grbl so go with the GRBL-M3 (1.1e or earlier) device in LightBurn. Ideally, you would upgrade to GRBL 1.1f and then use just the GRBL device.

Jumping in at the end of a post is less than ideal when wanting support. It might get buried or missed. ![]()

Any time you debug something, go back to where it worked and look at what change(s) you made to break it. Did you keep the original working configuration of your grbl settings?

IMHO… All things, including both LED and Tube lasers have a definite life. It’s rare for me to run any device at 100% (spindles are an exception.) My LEDs lasers are never run over 80%. Sounds like you have lots of hours at 100%. How do you know what the output of the device is at this point?

About pwm…

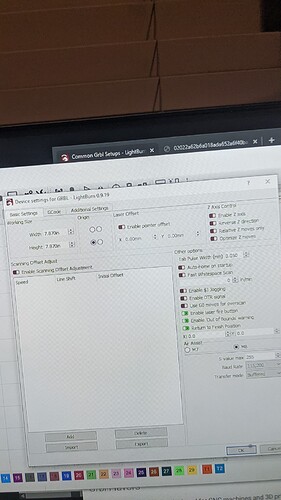

The output of the grbl boards are based on a pwm with an 8 bit value. Meaning only 256 different steps are available. So if the laser max is set at 1000 watts, selecting 50% power (or 500 watts) still generates a 50 % duty cycle. However both controller and software configurations, need to match for the math to work out.

This is the general idea of how the pwm works. For a setting of 1kw, it does something like this. 1000 (watts) / 256 (steps) = 3.9 (steps / watt.) When you ask for 500 watts it computes it by 500 / 3.9 = 128, which is the value sent to the pwm register to generates a 50% pwm output. Pretty much works the same way with analog voltage controls, just an extra step.

As a suggestion, when someone asked what and where you changed something an answer of “I put $30=255 and changed the other setting in the device settings menu.” leaves them wondering what “other setting in the device settings menu” did you change… Assume they know nothing of what you’ve done and add detail. Devils in the details.

Best of luck, hope you’re not out a device… take care (8’)

What @jkwilborn stated was worth its weight in gold, and then some.

People spend their time trying to help so the least the person having the problem can do is look at the dialog window and use the terms in the software. Making it all a guessing game usually wastes lots and lots of time and on the LightBurn side those people could have been helping many others with that time.

As for running things at 100% and damaging or lessening the lifespan it goes for almost everything in life. Run your car at 100% power and you’ll likely damage something or someone. Run any motor at 100% power and it’ll get hot, bearings will wear and wires might burn. As for lasers, it’s all about putting power on a spot of material and making it heat up. If you get only a light brown color at 50% you can try increasing the power but a better idea is to start lowering the speed. If the slower speed needed to get the desired results is unacceptable then you can try increasing the power and increasing the speed. If you get to a point where 80% power and a slow speed is not enough you have no choice but start increasing power or making a 2nd pass and have to start thinking about replacing the laser element.

What distance is the laser from the wood? How did you determine that distance? It kind of sounds like you are too far away or too close? Is your laser focusable? Mine is non-focusable and the optimal distance is about 18 mm.

Thanks for the post! Towards the beginning of me getting used to LightBurn I didn’t think about recording my settings. To be honest I didn’t even know what the settings meant, I just tried to find other people with similar machines and copy their settings. It wasn’t so much debugging as it was just trying a bunch of different copies.

I haven’t thought about burning out the laser’s power. That is certainly a possibility.

Thank you for the breakdown about pwm. It is very understandable. Also good point about the vagueness, I should have been more clear.

Now that you’re mentioning the possibility of the laser itself being burnt out, I think it’s a good investment to just replace the laser all together, to something that was made with the intention of working with LightBurn.

The speed that I would have to have been going at to get a burn at 50% would be unusable. As it was it was already taking far too long to get anything done, going less than 100mm/m on fill + line would have essentially made the laser worthless, so I was sure there must have been another problem. The advice is good for working lasers tho, so thank you.

Oh wow that close? I have at least 2 inches between the laser and the wood. It depends on the size of whatever I’m trying to burn, so I can’t give an exact value, but it’s definitely much farther away than 18mm.

It should be based on your lens focal length and has little to do with the material unless you know what you are doing and you are setting the focal length to a measured position below the surface for effect or multiple passes. The lens defines your focal length and how far from the work material your laser head is. CO2 laser lens focal lengths are often around 2" while diode laser lens focal lengths are around 1/2".

I did forget to ask you if you had a meter to see how much current your diode was using? And how hot is the case it’s in or it’s heatsink???

Great that I was of assiatance, I retired from software engineering and have used many software products. The greater the ability the more complex and difficult they naturally become. Saying that, LightBurn has been so easy to get it to do things, that it’s become a joy to tackle a new problem with it. So much so I can see it stimulates peoples creativity via it’s power and simplicity of operation.

The hardware’s got the magic, the software’s the magician. LightBurn pulls some neat magic out of the Ruida controller too.

I use LightBurn on my little CNC3018 when I mount my 30 watt led laser on it. I have a grbl based Woodpecker 3 axis controller, stock or similar to on most of the low cost cnc machines and it works fine. I can even control the z axis via LightBurn.

These system basic operations are pretty simple. The more you know the better you can figure stuff out. You learn by asking, not by osmosis.

I’m sure there’s a list somewhere of the LightBurn supported controllers, Maybe someone will post the link? I fried mine and it cost me $34 replace it. If it’s a solid state laser, it’s the control board that’s the issue, not the laser. Lasers are pwm controlled, and as long as LightBurn knows how to talk to the controller, you should be in ‘fat city.’

Good luck, keep in touch and let us know what you find.

Take care… (8’)

You should be able to turn your diode laser down to 1% and get output. At least low enough to be able to focus the unit. Still wear glasses, no matter what, this is when accidents happen.

Double check and make sure all your mirrors and focus lens is properly adjusted. It solved my problem

he doesnt have mirrors, but making sure the lens is clean is a good idea

I found my problem was alignment and focus issues

was this issue fixed I’m having i believe the same issue…

PXL_20210426_044507367|281x500

I have the same laser and have had the same problems. In one of the broken english videos that I watched they mentioned that the laser should be approximately 1.5" from the material. Also, make sure the laser is focused. Do this with your green glasses on and put the little piece of silver paper that came with your machine under the laser. Click on “move” in the counsel and in there you can click on “fire” which will turn the laser on. Keep turning the laser (I believe counter clockwise) until it gets really tiny. Try your laser like that.

Yeah, that’s why I asked; it looked very far away in your photo. If mine was that far away I would experience the symptoms you are seeing.

For reference, at 100% I get a deep black at 800 mm/min, dark brown at 1200 mm/min and a nice medium/darm brown at 1500 mm/min.

Mine might be a bit stronger than yours but you should be getting an order of magnitude better results.

@kushn your profile says you have a 40W laser on a 3018 machine… All the 3018 machines I’ve seen are open frame machines and considering a 40W laser tube( there are no 40W diode lasers ) are almost a meter long things don’t add up or this is one heck of a frankenstein machine.

And if it is a diode laser you really should not be running at 100% unless you know and accept that it lowers the lifetime rating rather quickly.

Might I also add that if you do not know what your focal length is of your laser and how to adjust to get the smallest dot on top of your material you should step away from the laser and learn about the machine you are operating with your remaining good eye.

I have had this laser working flawlessly before upgraded to a new one but fried fan with static shock so had to use old laser but can’t get it to work, i got it focused to a pinpoint, and also is 20mm fixed focus