Well, I figured it was about time to formally check the levelness of my table on my 700 x 500 Red & Black and see if it needed any adjusting.

It did.

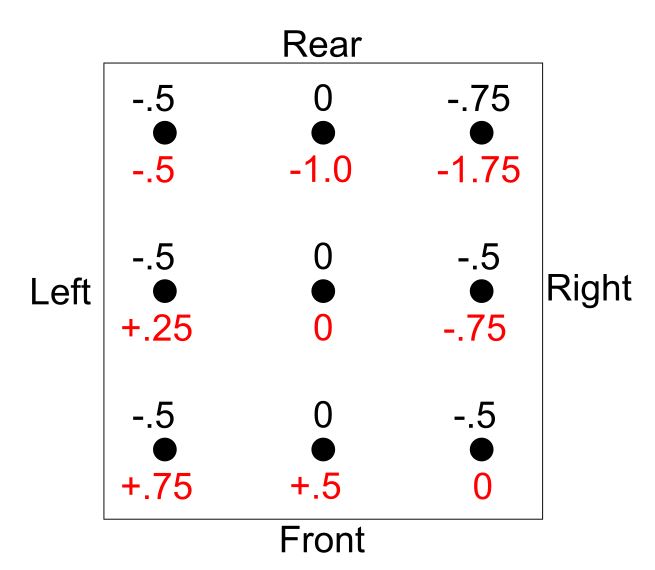

I drove the laser head to the center of the table and measured from the nozzle to the table. I called the distance at that spot spot "0" and all other measurements are + or minus from that reference.

It was pretty bad, with about 2.5mm difference between left front and right rear.

I loosened up the belt and adjusted the jack screws to get the corners fairly even. It took a couple of tries to get it right but it’s a lot better now. Unfortunately the table is very slightly bent and is a little high in the center along the x axis. It’s only about 1/2 mm high so I’ll live with it for now.

FWIW, the screws on mine have a 4mm pitch, and the pulleys have 15 teeth, so an adjustment of 1 tooth = ~ 0.27mm change in height.

The tensioner pulley nearly made me scream with frustration.

There’s a bolt that goes through the bearing and then through a slot in the floor with a nut on the bottom. It’s an easy enough thing to put a wrench on the top of the bolt and loosen it, but once loose it can’t be tightened again because the nut just spins along with the bolt. It’s way in the back of the machine so even laying on the floor I couldn’t reach both the bolt (inside the machine) and the nut (under the machine) at the same time. My arms are about 6" too short.

I finally ended up welding a little lump of steel to the nut that sticks up through the slot to keep the nut from turning. The belt is MUCH easier to adjust now!

Anyway, the rear corner could use about one more tooth of rotation on the screw to bring it up a touch more, but it’s much better than it was.

Here’s a little diagram of the before and after (red and black) heights for the silly thing.

And a couple of photos showing the adjuster lock nut mod with it’s little “anti-spin tab” sticking up through the slot in the floor. It will be SO much easier to adjust next time.

Anyway, slowly getting the Red & Black tuned up and road worthy.

Gotta replace the cooling fan for the electronics cabinet soon. That sucker rattles and vibrates and makes all kind of fuss and commotion for the little bit of air that it moves. Drives me crazy to listen to it.