Hi there! I’m using LightBurn for my Laser for a few months now. And I was wondering if somebody has used LightBurn with a CNC Router or a Plasma cutter. I’ve build a universal CNC machine that can Plasma cut or with an other attachment drive a router. I like LightBurn so much I want to use it on my CNC even if it means I have to change my controller board. Any suggestions??

LightBurn does not support driving additional cutting tools and does not have the specific features required to support these. You could output the gcode for a design then post-edit to adjust/add the code needed to fully accomplish your desired outcome.

We do want to support other tools in this space (plasma, router-based CNC, vinyl cutters, and so on) but these would be a separate offering from the current LightBurn.

Thanks for your explanation. But I’m a bit confused, it’s hard to believe that this version of lightburn could not move x,y and z-axis on a CNC machine and turn a plasma torch on and of. In my expectation this is all the software has to do. I only wish there is someone who could explain what breakout board is compatible with lightburn. But if it isn’t possible than I will wait for the right version of lightburn.

Move and turn the thing On and Off? I think there is a bit more involved. ![]()

Yes you are right, but basicly is doesn’t do much more than a laser cutter does. Or am I wrong?

If the machine has proprietary communication methods, I’ll have to buy one, learn how to use it, then reverse engineer the comms. That’s usually the hard part, and I need to do this for each supported machine.

Plasma won’t use raster or image engraving, so I’ll have to remove those from the UI, and they sometimes have touch-off or strike control to get the plasma started at the beginning of a cut. Other than that it shouldn’t be too hard.

I think what the other guy commented is similar to what I am trying to do. I have used open builds rail to create a basic 1M square XYZ build area for the purpose of doing CNC Plasma cutting. I have Bob CAM software to generate the G_code, but it is such a hassle to use. I love the simplicity of Lightburn, and I suspect it could easily be used for that. My plasma is a smaller Chinese unit that has a CNC port, and does not require a touch off to start. I would think it could be a pretty simple addition to make some features for the maker community that does not use a proprietary machine. My controller is the Black Box off of Openbuilds, and it is GRBL compatible, as well as others. Love to hear if there are others trying to do the same thing. Precision Plama cutting is awesome, and lightburn has the ability to make it very easy.

Can you give a link to the plasma machine you have? I’d be curious.

Here is the link.

I also own a pilot arc plasma cutter. It doesn’t need to touch the workpiece. I build my100cnx100cm Cnc machine out of scrap metals.i have a usb Mach3 breakout board (the red one with the bird on it, Gcode compatible) and it works but it would work so much better and easier when it would work with Lightburn.

It wouldn’t be terribly difficult to use LB to generate your gcode, then run that through some Python script or something that changes little things that need to be fixed. It’d probably take less than a week if you were moderately capable or already familiar with programming.

building stuff I can, but this… I wouldn’t know where to begin…

Then maybe you could even get lucky and LB outputs proper gcode already. It wouldn’t hurt to check LB gcode with gcode you already have, and compare the two.

Well that’s the thing, I don’t know what ‘virtual’ machine I must choose to get proper Gcode output

Try starting with the GRBL-M3 profile for your comparison. Using the GRBL-M3 profile will produce the least verbose, and most generic GCode - You’ll see M3 for laser on, and M5 for off.

Okay, will try that, thanks Rick!

I hope it compares to the mach3 Gcode, that would be great!

Hi, is it correct that I don’t see that gcode for Z-axis is being generated?

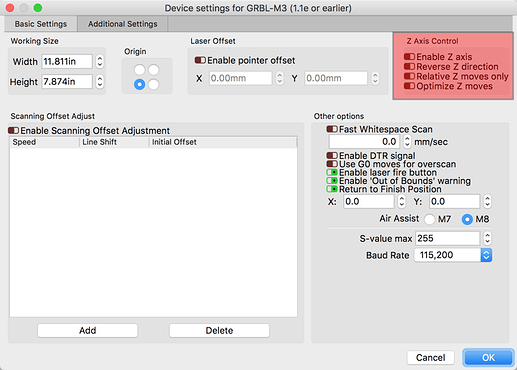

Look in the ‘Device Settings’ to enable Z control. Restart LightBurn and then the Z axis moves defined in your job will be emitted in the generated GCode.

Correct, lasers do not move the Z in typical (simple) use. There is no “plunge” for every cut like there would be for a CNC mill.

If you were to enable something like the material thickness (focus height) or multiple passes, then you would get Z moves.

Thanks again… i’ll try