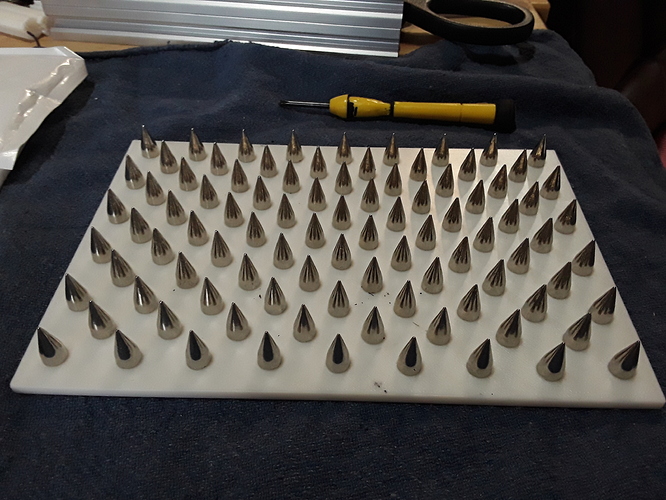

I cut out the aluminum late this afternoon on a water jet. I just finished screwing in 48 spikes. I’ll give it a try on the laser tomorrow.

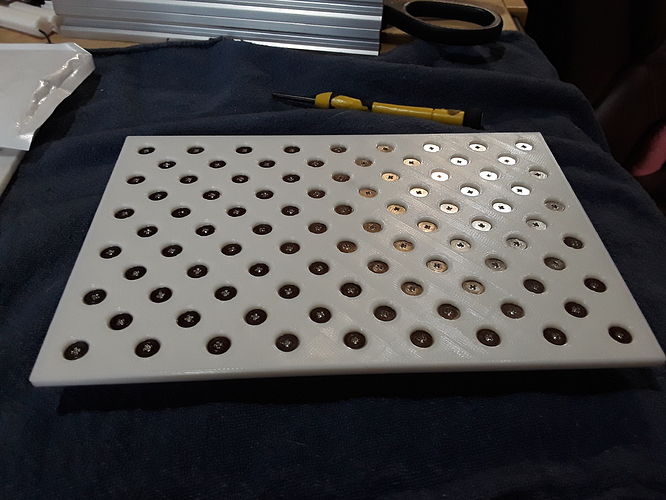

Here is my nail bed, i chose slightly shorter spikes but they are ok. There were some bad gains in my delivery (from China)

It takes a lot of time to level the bed so that it has the same height in all places.

I only have 4 long M6 screws with counter nuts to hold my bed and because the K40 bottom base plate is very uneven, each screw has its own height measurement. But now everything is perfect again and I am very satisfied.

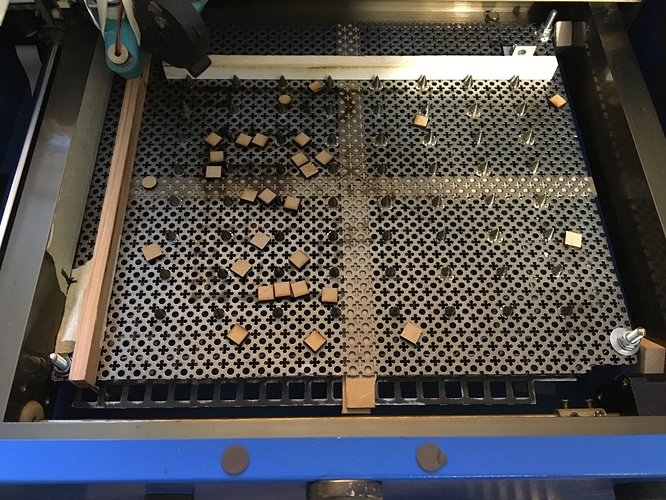

The wooden cross should be replaced with distance screws, I know, I know …

By the way, the nail bed can be easily and quickly removed, it is only on the top of my real bed.

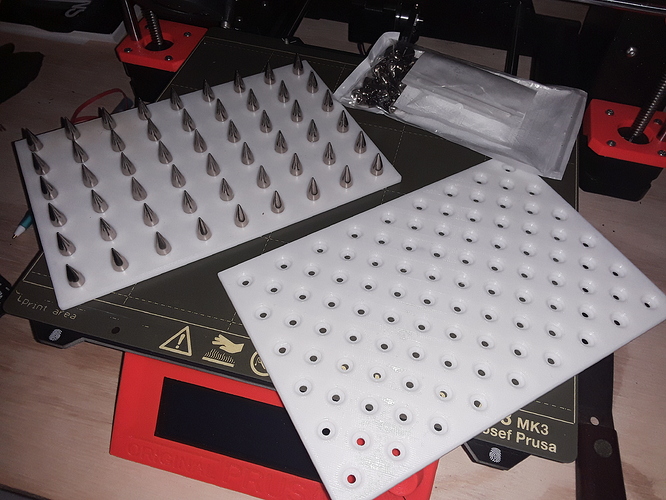

For use with diode lasers and the smallish stuff I do (craft-sticks, small photos, etc), I migrated my first printed plate with 20mm spacing (1st photo, left) to a denser plate with 10mm spacing. Used up all but a few spikes in the 100-piece package

I bought this one to use with the spikes.

https://www.amazon.com/Wall-Control-30-P-3232GV-Galvanized-Pegboard/dp/B001J6FSDS/ref=sr_1_14?dchild=1&keywords=metal+board+to+hold+tool+on+garage&qid=1590012317&sr=8-14

That looks like it will work nicely.

It’s a bit unfortunate that you got a galvanized, black steel is better for the purpose as it does not emit zinc.

But zinc helps with colds. ![]()

Ohh, I thought otherwise our friends on the other side of the Atlantic are using hydroxychloroquine for this kind of harmless lapis…

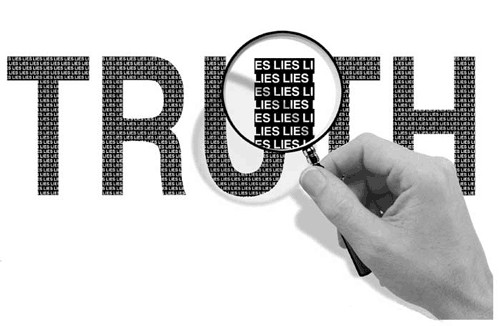

Always check what is reported as truth.

I learned years ago about the dangers of working with galvanized metal in a welding class. When superheated like during welding or plasma cutting, it does give off lots of poisonous gas. If the area is well ventilated and you wear a decent respirator it’s safe to do. I doubt an out of focus laser beam moving at speed will cause any major poison gas issues but I’m not an expert.

You can always just neatly put a sheet of aluminum kitchen foil over it before screwing in the studs. The studs will hide the holes and hold the foil down. My first laser was a K40 and I used a lot of foil over the years wrapping levelers and supports. I even covered the floor of the K40 because it made cleanups every few months easier. The old K40 burned out, but aluminum foil is still a great laser safety tool.

Yes, I would not overestimate the risk either, but if you are aware of the problem in the beginning you can hit a more qualified selection of materials.

The most important thing is that you have a strong suction for your laser machine and corresponding fresh air supply in the room.

Skål friends

To get back to your first post in this thread, I feel the same way with Inkscape. I have used it for many years and really like the program, but Lightburn has taken over most of my design / construction tasks. Just Lightburn’s latest note editing modification with trim feature is so useful. I firmly believe that if the development progresses at the same speed as up to now, we have a laser management program with so many cat-like features that will cover all the basic construction tools we dream of. The development process of Lightburn is so dynamic, it is absolutely amazing.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.