Just started doing leather and i seem to be missing something. When laser is doing the fill part it is burning through the leather like im trying to cut that portion out. Is there a setting i am not using that will make this stop or is it a power setting? currently using 2000 spd 15 pow 400 dpi. Thanks for help!!

You could add a little more detail, such as a photo along with the power of your laser.

You should supply the units you are using, they can be mm/s, mm/m, inches/s, inches/min…

Most use inches/second, but we don’t need to guess if you will tell us…

It’s also nice, but not required to let us examine the .lbrn2 file so we can see how it’s set up.

Good luck…

Take care

Sorry Jack yea I thought about that after i made this post…hopefully this will give some insight

Laser is a chinese 80w Diode and I think its 2 diodes in the laser

I use inches/ min Lightburn shows it as better to use for diode but Im open for changes

settings are as follows:

$0=10

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=0

$11=1.000

$12=0.002

$13=0

$20=0

$21=0

$22=0

$23=0

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=0

$100=80.000

$101=80.000

$102=250.000

$110=8000.000

$111=8000.000

$112=500.000

$120=500.000

$121=500.000

$122=10.000

$130=38.000

$131=35.000

$132=200.000

If this is the one I’ve seen before it’s actually a 40 watt. It was a Neje sold by a vendor and the same animal on the site is 40 watts… It’s sometimes difficult to find the truth on these.

One option is that you can figure the ‘input’ wattage (supply voltage * current) and take about 10 - 20% of that for that possible output value… If you have a 12v 80 watt laser it should have a minimum power supply of 80watts/12v or 6.666 amps available from the power supply.

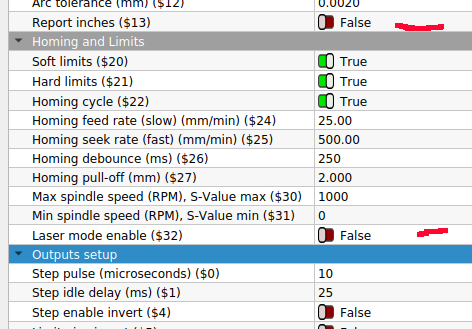

Looking at the configuration, I think $32 needs to be set to laser… Mine is running as a ‘cnc’ machine, so my values are not correct for a laser, but with Lightburn I can ‘Edit → Machine Settings’ and change ‘Laser Enable’ to ‘true’. This is better than entering this in the console as $value=setting. Use the GUI in lightburn, it’s in your language.

You say you work in 'inches/min/ the controller reports $13 (Report in inches) as 0 which sets the machine to mm. Set this to ‘true’ also. Mine is false since I use mm.

If you use mm or inches, it rally doesn’t matter. Some machining operation some ‘units’ are easier than others. Most of my stuff is fast and small, co2 laser. If I were machining the turret of a military fighting tank, the machine will probably be moving very very slowly and measured its speed by minutes. So it’s kind of applicable to ‘machining’ in general, which is where all this came from.

Don’t forget to ‘write’ it back to the controller and save the new version of your configuration. Name these uniquely so you can find the original and any other variations you make.

Suggest you open the machine settings and immediately do a ‘save’ so you have the original configuration available when you break something…

With it set to mm, your machine thinks it’s work area is 38mm x 35mm x 200mm (z axis) these are reflected by $130 (X limit) through $132 (Z limit). 200 mm (or inches) is rather large for a Z axes available ‘stroke’ length…

I’m trying to say some of the configuration items (in the $ list) are apparently not correct.

Did you set up your machine as specified in the Lightburn grbl setup? Doesn’t appear so… as $32 is specified there to be enabled.

There is also documentation on the Coordinate and Job Origin you should read and be familiar with.

Good luck…

Take care

Be looking for pictures of your beautiful work… ![]()

![]()

Hey, you may already know this but some leathers can contain vinyl which, if lasered, will cause musturd gas so take extra care!

If they have vinyl they are some kind of synthetic… Yes I’m aware of vinyl, but these is ‘laserable’ vinyl out there they use for stickers and such.

Here’s a 20K machine that was used for vinyl cutting

Thanks Jack that was it the laser enable mode. Thanks so much will put a picture up soon really appreciate the help.

Thanks for reporting the fix…

mark it solved…

Take care

Have fun…

try wetting the leather first with water.

you can use a spray bottle with water, or if its thick leather (4mm+), get it soaked in the sink, leave it flat somewhere so it barely starts to dry, then use it.

the process is called ¨casing leather¨