When I cut with the laser, it seems like the beam is extremely wide. I have an ortur lm3 20w. The torch is set to speed 300 at 100% power and even 4 turns are not enough to cut completely and I am using 4mm thick plywood. What could be the reason?

Your focus is not set to the correct length. More speed and more passes will reduce the charcoal around the edges. FWIW my 10w ortur laser takes 100% power, 1000mm/m and 8-12 passes to cut through 4mm wood.

Type ov wood makes a difference.

10w, 2.8mm Baltic Birch plywood, 800mm/m, 80% power, air assist, and 5 passes.

Well this is either strange or maybe a defect. I tried to run on cut 100% power 15(!) passes and 600 speed, and it’s not completely cut. What’s wrong here?

How is your focus distance set?

Is your lense clean?

Is your beam aligned?

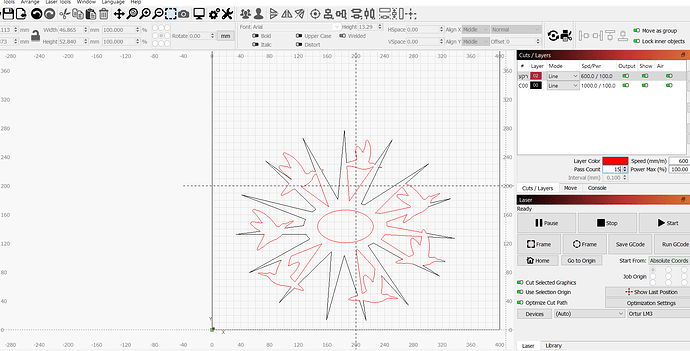

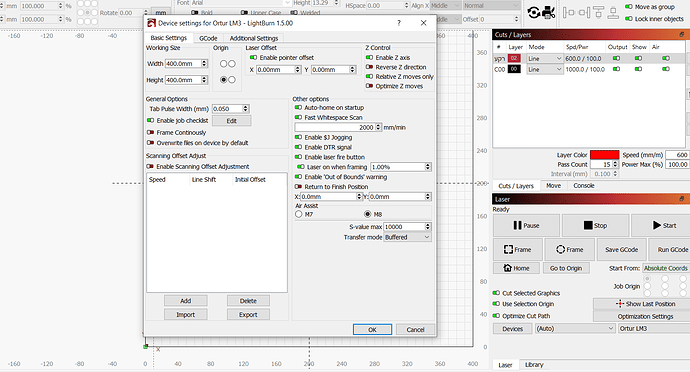

Please SHOW us your settings window

Please SHOW us your preview window

What is the advertised size of your laser spot? .1mmx.08mm?

Is your laser a diode laser or a CO2 laser?

Make your focus closer and farther away by 5mm at a time, for at least 3 changes to closer and farther.

Label your tests and show us the results.

Draw a simple line box with a single pass at 50% power and 1000mm/m speed.

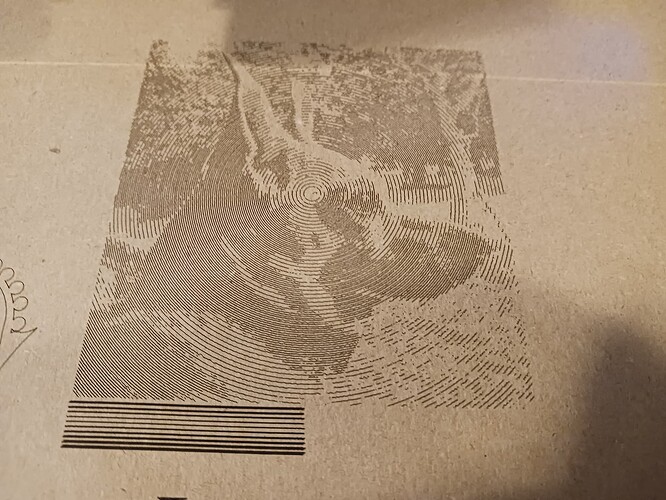

Note the parallel lines pattern under the engraving of my dog in the photo below. You may, or may not, have a fully implemented Z-axis as I did here… but this demonstrates how the line thickness varies on either side of best focus.

In this 10 line gradient pattern, each line is 2mm different in Z than its neighbor to either side. So over the 20mm range from “too close” to “too far” you see the line thickness varying with focus distance. To find best focus from this pattern (drawn bottom to top), I count lines back to the finest/thinnest line and multiply by 2mm… and then lower my Z-axis from its finish position by that exact amount.