Both can do either. If you’re going to do more cutting than engraving especially of thicker materials get the long focus.

It looks like there’s a lot of CO2 laser setups available on eBay under $1400. Am I crazy to consider that? Are there any specific models or sellers anybody recommends? A 30cm by 50cm machine would easily cover all my needs.

Thanks,

Josh

I have a 3050 50 watt Omtech “China Blue”.

Purchased it to learn how this stuff works, so it’s had a bit of modifications. I paid $2k for mine a year ago. I’ve had a great time with it. Haven’t hardly fired up the LED laser since I’ve purchased it. So it was a good choice for me.

It has a Ruida 6442G controller, 880mm tube (44 watts) and a 60 watt supply for the lps.

The spousal unit says I don’t want to know how much I’ve spent on it since purchase…

I’ve been happy with it.

Good luck

Do they mean your electric bill, or materials and modifications?

Spousal unit = wife

Not other than the drawbacks we’ve already discussed at least in terms of CO2 vs diode. Not a crazy idea but not one you probably want to jump into without consideration and acceptance of the drawbacks.

The other consideration then is the vendors and quality of the ebay sellers. They can be quite hit and miss. Some of the more prominent vendors like OMTech you see listed here quite a bit. People have had issues with them as well but it seems they at least make an attempt to address those issues.

Your mileage may vary with all vendors. Maybe circle back here for reviews on a specific vendor/model if you find one that catches your eye.

lol, I know what you meant. ![]()

Most (if not all) of what I do for engraving will be uniform, I don’t need a lot of shading level detail. Besides that, drawbacks are physical size, and cost?

By the time I would get everything for the Ortur, including an enclosure, I’m already at the $1K mark. So a little more for a CO2 model doesn’t scare me on the price…especially while PayPal has 0% available.

The size will be a small issue, it may wind up living in my basement near a window.

Do I really need a chiller beyond the water pump that comes with some of them? My use will be fairly moderate at best. I don’t see me running the thing constantly at all.

Is the regular exhaust going to a window good enough, or do I really need to consider fume extractors or upgraded exhaust fans?

Is there anything else I should consider?

Thanks,

Josh

Main operational considerations:

- Size as you’ve mentioned

- Venting - most find the existing venting solutions inadequate especially for cutting operations

- Cooling - this will be determined by service load. But depending on laser power I don’t think it’s particularly difficult to saturate the cooling ability of the low-end solutions. And lack of cooling is the surest way to kill your laser.

- Air assist - You’ll pretty much want a continuous source of air minimally to protect the lens from debris, and more for actual cutting.

- Bed considerations - you’ll need to optimize this for the type of things you engrave/cut.

- Power needs - if you get a 240V unit you’ll have to accommodate for this, especially if you’re in the US or other 120V country.

My typical media will be something like this .5mm acrylic. Would that be something worth the extra effort in cooling and exhaust?

Wouldn’t I have the same concerns for air assist and ventilation with a diode laser?

Bed considerations- I have no idea what to think about there. I think most of what I looked at had blade and honeycomb beds included. For my acrylic stuff, do I need something different?

Power- I’m already planning to avoid anything that isn’t standard US voltage.

I feel like a CO2 laser is overkill for my needs, but the 3050 bed size is plenty for me, so it’s very tempting. I also feel like there’s a lot of tradeoffs with the diode solutions that make them less desirable. If there was a 30cm x 50cm diode solution, that people like / find reliable, that would be interesting too. But in most cases, the diode setups still seem to require a lot of extra effort for exhaust / enclosure needs.

Thanks,

Josh

That material is .052" or 1.3mm.

I cut 0.93", 2.4mm clear acrylic for cut/drill templates pretty fast on the co2.

Good luck…

Oops, wrong one then.  But it would still work. The ones I have now that were made for me are .5mm. That 1.3mm would be a little thick, but it would work fine. The thickest I would need to cut is 3mm, but that’s rare.

But it would still work. The ones I have now that were made for me are .5mm. That 1.3mm would be a little thick, but it would work fine. The thickest I would need to cut is 3mm, but that’s rare.

On the other hand, I could possibly cut turret board holes on the laser. Black G10 shouldn’t be a problem, right?

Thanks,

Josh

I’m a big fan of trying and adjusting as required especially if you’re within general parameters. If you try to go too far ahead you risk solving for problems that don’t exist or introducing new ones that you didn’t anticipate.

Yes, in general. However, the speed of CO2 laser cutting creates exhaust gases more quickly which you need to address. Even if the overall volume of gases were the same the rate at which they are being generated is higher. Similar situation with the air assist. Also, once you have a CO2 laser everything is going to start looking like things you want to burn.

CO2 laser will give you more flexibility in the type of acrylic you can engrave and cut. Depending on the situation, a diode laser may get you a more detailed engraving. Not sure in this case though so deserves experimentation.

There’s really no way around this part. Burning in any case will create fumes. If you were in a really drafty barn or something you could get away with engraving wood or paper without a venting system.

I’m also considering getting the OMT 40W table top CO2 laser to mess around with that. Until I need something larger when my stocked panels run out.

What controllers work with it that are compatible with LightBurn?

I think my main hope right now is to get a good deal on a refurbished OMT laser. But in the meantime, it might be fun to mess with something else. I like that it’s a fully enclosed unit for the same price as the diode stuff…even if it is smaller. Is it junk, or will it be useful for the smaller stuff I’m doing?

Thanks,

Josh

The two most often cited drop-in replacements are Cohesion 3D ($230) and Mini Gerbil (new model 3 out for $115).

You could get any number of other boards to work with some work including the DSP controllers. The other two are just the most common and are specifically intended as drop-in replacements to the mounting level and are well supported.

There are tons of folks doing lots of good work with K40s, especially with some upgrades. They shouldn’t be underestimated.

Drop-in replacement is my jam. Is there anything about the Cohesion 3D board that warrants it costing twice as much as the MG3? A quick glance from a PCB design perspective makes the MG3 look superior, though I have no perspective on real-life performance.

Are there any specific threads or upgrades I should be considering? I know the laser tube is often upgraded, but I’d like to put that off if I can. One guy on youtube linked to a bunch of Cloudray upgrade stuff for it. There’s too much stuff to consider with all of this, I can see it becoming a time consuming hobby just tinkering with this stuff.

Thanks,

Josh

We are all consumed here.

The beauty of the K40 is cost/performance. It is very low cost and is big in the performance end, especially compared to an led laser.

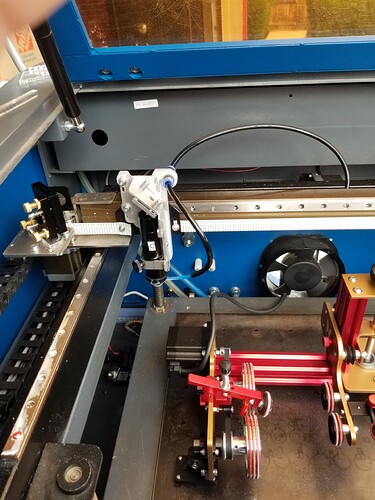

Any of these can be stacked with ‘additional’ parts and time… like mine…

You can always add as you see fit.

![]()

I believe the major differentiator for Cohesion 3D is that it supports 3-axis control whereas Mini Gerbil is limited to 2-Axis. I think Cohesion 3D may have been earlier to market as well. Awesome Tech has been quick to refine the Mini Gerbil over its various iterations.

As far as upgrades @jkwilborn has touched on it. You’re really chasing the dragon with this stuff and as you say, becomes a hobby on its own.

I also have the Atomstack A5 Pro and had the same issues with cutting. I came across a recommendation in this forum to look at the M50 upgrade module which despite its price I picked up. Easy to swap in and it did solve my cutting problems. Much faster and cleaner. Happy with the Atomstack now.

I think I’m pretty well set on the K40 now. I’m going to get the latest version that has the temp readings on top.

I figure I should also get a chiller and air assist while I’m at it. Is the CW-3000 worthwhile, or is there something better I should get? I’m not going to spend more on a chiller than the machine.

Thanks,

Josh