Is there a business local to you that makes ceramic pottery or other glazed art? Perhaps they could help.

Many ceramicists formulate their own pottery glazes and use a wide range of chemicals for coloring, including TiO2. I found it locally in the US at a place that sells to ceramic artists.

Maybe a friendly potter could help you out?

I would look into that before I run any zinc under the laser, if I remember correctly zinc is really REALLY toxic when vaporized.

I do not know how zinc oxide reacts to laser beams / combustion, but as such it is very harmful in the watercourse. In the video shown on YT, it is just flushed down the drain. If it ends up (in a certain amount) in biological wastewater systems, it destroys the bacteria on which the whole water treatment is built.

It’s a shame, it otherwise looks very promising for engraving of glass and tiles.

" Welding galvanized steel has gotten a bad reputation over the years (rightfully so) as the fumes produced during welding can be incredibly dangerous to the welder’s health" Welding Galvanized Steel | Metal Supermarkets - Steel, Aluminum, Stainless, Hot-Rolled, Cold-Rolled, Alloy, Carbon, Galvanized, Brass, Bronze, Copper

yeah I would give that a hard pass unless absolutely necessary.

Zinc itself is a scratchy substance when it gets overheated but we must be aware that zinc oxide and zinc are two different things. If there is something to “neutralize” the process water with, it will be very welcome. Maybe there is an environmental chemist out there who can shed light on the subject a little more professionally correctly as I do with my basic knowledge.

I am not an environmental activist but I know that every year several groundwater wells are closed in my small country due to pollution.

I’m so overwhelmed with stuff I need to do right now that I have no idea when I’ll get around to messing with this stuff, but I finally got a chance to go fetch the mail and found a box of fun waiting for me.

I still need to assemble a turntable of some sort to spin coat tile but I have this assortment chemicals to play with.

I was able to do a bit of experimenting with red Iron oxide, and it fused to the tile well although the results came out as a dark black. I am wondering if using a porcelain glazed tile may not be ideal for getting colors.

Since the coloring is a reaction with the glaze, I have no doubt that the glaze formulation plays a very important part in the final color.

Has anyone determined what RPM to spin the tile for a uniform coating? I have a paper design for a spinner, but was waiting on this data to spec the motor.

Built my spinner today. Was just getting my photos together, will post soon.

So far, the short version is: Doesn’t work well for me yet at any RPM.

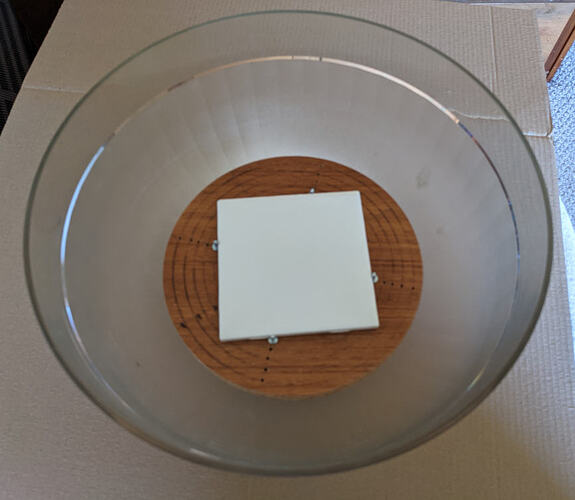

Well, I built a Spin-O-Matic device today to try spin coating TiO2 on to tile.

It sucked.

The machine was easy enough.

I dug through my DC motor box and selected a likely victim, dug through a pile of misc and found a pre-cut circle of wood leftover from a previous project, complete with a 3/8” hole that pressed snugly over the shaft of the motor. Woohoo! Life is good!

I drilled a bunch of small holes in the spin table so I could stick some pop rivets in to keep the tile from getting away at speed.

I had an old plastic salad bowl full of pistol brass waiting to be reloaded so the brass went in a metal can and the bowl got a new job as a “spew shield” to contain the mess.

Hooked it up to one of my DC bench power supplies so I can adjust the voltage/speed and yippee, I’m in business!

So. I mixed up some TiO2 in some some ethanol (Everclear) and stirred it up real good. In about 3 seconds it all settled out.

I mixed it up good again and immediately brushed a thick sloppy coat on to the tile and spun it up to speed and the stuff clumped and streaked and left a totally unsuitable coating.

I tried a wide range of different spin speeds, different ratios of TiO2 to solvent, ethanol, isopropyl, acetone, plain water, water with a touch of dish soap to change the surface tension… the results sucked every time. The stuff really wants to clump up as it spins off. The best results were with plain water. For some reason the alcohols seemed to make it clump more.

Obviously more experimenting needs to be done….

I’ll probably try spraying some to.

At least it didn’t take long to put the Spin-O-Matic together. It’ll probably come in handy for something.

Photos of Spin-O-Matic…

is the titanium dioxide powder that you have food grade? I remember reading somewhere that the food grade stuff was more finely powdered than other varieties, this might be a contributing factor to the settling you are getting. For me I have been finding one tbsp of TiO2 to 3, 1.5 oz shot glasses of ethanol is about the best mixture I have gotten. I do see some settling within the mixture, however the ethanol retains its complete white opaque hue, which indicates to me that the solution has reached its maximum saturation point and some settling has not really caused me any difficulty.

I did notice the tendency of the powder to clump on the tile when I tried using a hand spray bottle rather than the airbrush which when lasered definitely produced sub optimal results.

In the semiconductor industry, wafers are spun without the material and, while spinning, the material is carefully flowed into the dead center of the wafer so centrifugal force causes spreading immediately.

However, I’m not surprised the powder separates out so quickly. It may need a more viscous solution to keep it suspended until it can be spread on the surface.

I think this was a good experiment and looks like an effective spinner. Good job, Hank!

Don’t know, probably not. It came from a place that caters to potters and the ceramics industry.

It seems ultra super duper fine to me, but that’s not a really exact number in microns or anything… ![]()

I can probably ask and find out more about it.

Yeah. I was wondering about a little glycerin?

I mixed up some 5:1 H2O /TiO2 and sprayed a couple of tiles. They look OK, I’ll run them tonight.

I also heard borax provided better adhesion to glass, I have not experimented with that at all yet myself though.

Now that’s funny, I was just contemplating adding a little borax to the mix. It’s a common fluxing agent for glass. And I’ve got some.

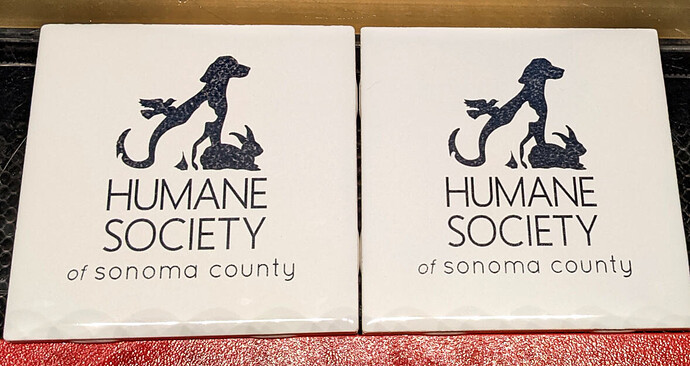

So I had pretty good luck spraying TiO2 on the tile.

First attempt spraying, 3 medium/light coats with 10 minutes dry time between. 5 parts H2O, 1 part TiO2.

These were run on a 80w red&black at 8.2% power, 44 mm/sec on the left, 50 mm/sec on right.

This is the darkest I’ve ever obtained on tile. Better than any of my spray paint attempts.

The small lettering is very nice and dark but the larger areas get blotchy. This is where I wondered if some flux like borax would help a little.

And in all fairness the blotchiness looks way worse in these photos than in person. But certainly there’s plenty of room for improvement.

Anyway this is a promising start and I’ll probably go further down this rabbit hole.

4" tiles…

What type of sprayer did you use?

Glycerin sounds like it might work. I don’t know about Borax, but that really is a mysterious type of material. I actually use that (1/2tsp:4oz water) to clean the char off of my 3D wood burning. It works well and seems to be a worthwhile experiment. Certainly less expensive than glycerin.

The one thing I would think about glycerin, which is an emollient, would be the drying time.

Badger model 400. (discontinued now I think)

Holds about 3/4 cup of juice.

I mostly use it for spraying kiln wash on shelves in a glass kiln.