Omtech 60W/50W Blue and Gray with Ruida 6224

Received new nozzle and 50.8mm FL lens.

I do not get good cutting on wood/plywood/chipboard.with settings I see folks using.

With nozzle tube seated all the way up I have tried FL setting from nozzle to workpiece of 17.5mm, 15.75mm, and 12mm. I done ramp test, 17.5mm seems to be appropriate setting. I made the line for the test about 15" on length with ramp 22" and raised at least 1 1/2".

Is there any advantage to lowering the nozzle tube, making the nozzle closer to the substrate? Or should I keep it all the way inserted?

I have never checked the power the Ruida Controller is set at. Any enlightenment on that subject would be appreciated.

BTW: I tried settings of 5 - 50mm/sec at 25-60 percent max power and Min power between 10 and 25 with little to no difference in depth of cut.

Meter reads 11 or 12 ma with 60% power.

I probably have missed something obvious.

I have the China Blue, or 50 watt…

I use that lens, probably the most.

Have you done a ramp test to see where it’s focusing? Probably the most simple approach.

https://lasergods.com/glossary/ramp-test/

I’m not sure which head/tube you have, as there are many, so that may help us help you.

Every one of these will cut differently and they will all vary by batch.

I use 12mm/s @ 60% for 4.5mm plywood. If there is more or less ‘glue’ or ‘holes’ it will require adjustments. Might have to bump the power by 10 to 15%, since I made adjustments on my power supply.

My Ruida has a ‘line’ file on it just for determining ‘cut’ or ‘focus’, like a ramp test. I use it frequently.

Is your tube rated at 20 mA or less?

Sounds a bit low for a tube larger than mine (880mm). Mine has a 21mA max placard. At the high end I’m comfortable with an 18mA setting.

Good luck

![]()

Jack,

Read my post again. I done a ramp test three times actually.

I hesitate to set my power around ninety or so and as you said, Yours cuts fine with some tweeking for different materials with a relatively low setting.

I tried to find some info on Omtech site and their community as to what output my laser should actually have to no avail.

I am quite sure I haven’t been able to cut well on basswood or birch ply from the beginning.

I bought the laser November of 2020. Ninety percent of time up to my surgery in July was spent engraving. Busy around our home trying to catch up with all the things I couldn’t do physically before surgery. Have only been in the shop two or three hours in the last 5 months.

When I get time I will see if I can find some information on what the laser is actually outputting.

Thanks for your help and here’s wishing you and yours a HAPPY NEW YEAR.

Processing: Screen Shot 2021-12-26 at 12.00.02 AM copy.jpg…

I found this information concerning the 60W Omtech. I am only assuming that they made this chart to allow for the actual 50W of my machine.

Power = 65-75 with18mA, Power = 100 with 30mA.

Your screenshot didn’t upload… Have to wait on it sometimes…

Sorry about the ramp stuff, jumping between some of these you think you read them, then find you missed something or have a different thread.

On a 60 watt tube, I’d think 18ma is conservative. I’ve been advised that the best ‘life adding’ current is about 18mA so I try not to go above that (I have a 880mm tube, about 44 watts out), so my upper limit is lower than yours.

30mA seems higher than you’d want to run. If 30mA is max then… mine is 44 so it to 18 and you max to 30 would give me a 22 mA equality for your ‘comfortable max’, if that makes sense…? I’d think a 22mA would be within a comfortable range. I figured that 44/18 = 54/x or X has to be about 22…

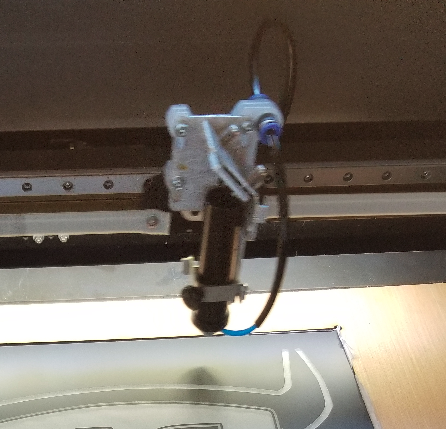

Where is the lens? That’s the critical measure length.

Personally I move the lens/tube as close as possible to the mirror 3 in the head.

As you can see. It shortens the distance the beam must follow and it eliminates the ‘pendulum’ type of issue you can get from it ‘hanging’ out, when there is a direction change. I’d advise the closer the better.

Some material, like the mirrored backing, I want a longer lens to keep the nozzle away from the metallic debris that is generated. Covers the nozzle and requires an increase in air pressure to keep debris from reaching the lens.

Good luck…

![]()

I discovered the lens was moving around causing jagged cut line. Omtech manual shows an “O-Ring” placed on top of the lens in a 50.8mm lens before assembling to the lens tube. Makes sense to me that it would stop the moving of the lens. I am going to see if I can find an o-ring of the proper size, lots of luck to me!!! Cloudray did not include an o-ring in the lens and nozzle package.

Concerning Max and Min power settings:

I looked in the controller, the default setting was at Max 60%. I changed it to 80% to test.

Will do another ramp test as soon as I can find an o-ring.

All of this being said: With the Cloudray nozzle and 50.8mm lens, the lens is placed at the very top end of the nozzle. Should the o-ring be placed directly on the lens making it an 18mm o-ring? Or on the edge of the nozzle around the outside of the lens?

Go down to the hardware store and pick up some o-rings, a little larger than you need.

Cut enough out to fit it into the tube. Doesn’t have to be perfect, just hold the lens firm.

I paid the big bucks for the silicone ones… don’t waste your money…

Seems to me the last lens tube I bought from cloudray had a mounting ring with a ‘cushioned’ side for the lens to rest against.

I had a silicon washer in a nozzle I am not using. It seems to be holding the lens just fine although I installed the 50.8mm lens in the original nozzle that came with the Omtech.

I cut 6mm birch ply with speed 15 and power at 35%. Nice kerf, clean cut. Tried to download a photo of a small puzzle I cut but after waiting ten minutes and it still hadn’t uploaded I just deleted.

Distance from nozzle to ply was 17.1mm. Plywood measured 6mm. Max amperage, 11 mA. That should help save my tube. lol

Speed correction: Should read 15 speed.