OMTech (which I also use) = cheap Chinese laser, painted, slapped with a brand and having 1 or 2 bells and whistles thrown on (Autofocus usually) and finally, double the price. Sorry I’m not answering your question, just trying to save you $45 talking to someone that knows possibly half about lasers as 75% of the people on here. I was considering the 35x51 Omtech because it was lower than usual ($4600) then went to Alibaba where I got my fiber laser and for the same machine that had a faster run time… $1999 w free shipping. No brainer, OT is pretty douchy!

I can’t confirm that. My OMT 60WATT CO2, which is in its 4th year in action, works and has worked all its time in my workshop without any problems. I have changed the extraction and invested in a professional refrigerator, I have retrofitted an amper meter (there is an already on the power supply) …

It may be I am “just” lucky but that is my reality. Remember, all those who write here about their problems with their machines are only one side, the other side - you don’t hear from those who are just happy with their machines. ![]()

Hope you will be satisfied with your original brand from Alibaba

I think you may have misunderstood me. It was a factual statement. I’ve been engraving 16 years and (the first thing I stated) also use an OMTech. It’s about three years old, was a 28x20” 60 watt until it was new tube time and I went to 80w. I purchased the “F” series 80w tube and guess what brand….OMTECH! None of this happened because they charge $45 for a half hour call to get an answer like he did. “It looks normal to me.” is trash customer service. I’ve had several lasers and not one was built outside of China. As for Alibaba, that was a fiber laser and I couldn’t be happier. My next one will be direct from china because better put, OMTech is a reseller of Chinese lasers and make buying one more convenient by cutting through all the bs with RFQ’s and all that haggling. with a heavier price tag. Take it for what it is. Fact. I’m not complaining.

That’s what I say / mean.

Omtech is “only” a sales and delivery point in the various countries, I don’t know what their customer service is like, I’ve never tried it. I’ve tried Cloudray, they were reasonably fast and professionally ok.

To the OP - did you end up resolving this? I have a new 100W 20x28 OMTech that has really bad wavy/squiggly lines. I’m in conversation with tech support but apart from having me check the belts and tension pulleys, we haven’t gotten anywhere yet.

I’ve tightened/loosened the belts, checked the lens to make sure it’s not jiggling in the laser head. I will do the circle test on all 4 corners to see if there’s a difference. Similar to the OP, this is only an issue when both axes are in motion.

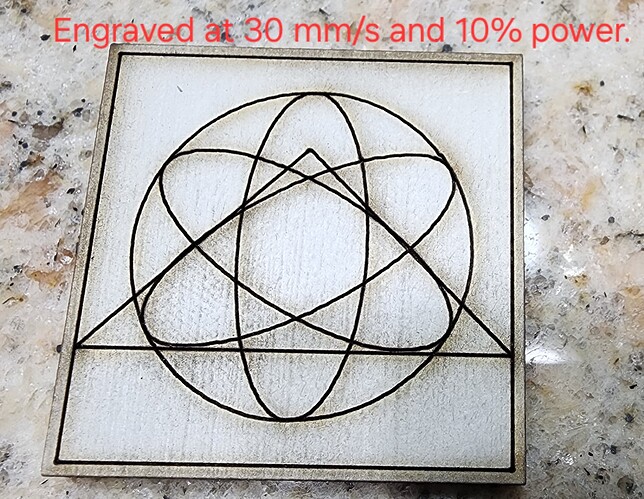

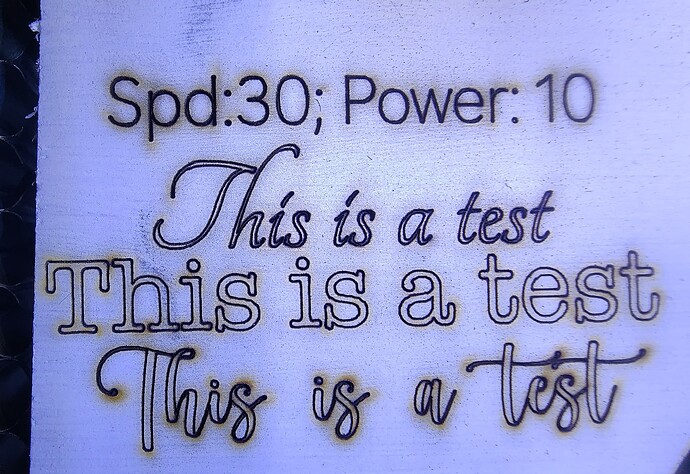

See attached image.

My Ortur LM3 does not have this problem at all so I know this isn’t normal laser behavior.

the difference between CO2 and diode lasers is the CO2 uses mirrors and the Diode does not. Look for wobbling mirrors, or even the tube and make sure the lens is snug and not wobbling.

I’ve checked and secured all those - mirrors, lenses, belts etc. Now tech support is asking me to try RDWorks but if it is a mechanical issue not sure how that’s gonna help.

0.05 - default I think as I haven’t messed with that before.

you can usually test if it is a mechanical issue by greatly slowing down the engraving speed. I would even go to create two vectors, a circle and a octagon inside the circle(not touching the circle) then engrave at your normal speed followed by an engraving test at a really really slow speed.

Just looks mechanical to me.

Here are some images of tests I’ve run this past week. 30mm/s seems pretty slow to me.

Figured I’d do some text as well and if you look at the second test line, all the curves are unsatisfactory. Or are my expectations just unreasonable?

There’s a lot to look for in mechanical issues like this. 30mm/s for a CO2 is rather slow and you still show the issue. Start looking at all the belts and how they fit and interact with the idlers and the drive gears. Check to make sure the belts are not too tight. Also look at the grub screws on the drive gears to be sure they are on the flat part of the stepper motor shaft and are tight.

Previously someone mentioned turning off air assist and seeing if that stops the wobble because the focus lens, if loose can wobble from air assist.

I am a noob to CO2 lasers - this is the first time I’ve heard of a grub screw. Kinda highlights the depths of my ignorance. If you have images of the grub screw and the idlers, I’d appreciate it. I’m going to google this too.

I did check the belts earlier this week and once I loosened the y-axis belts, another issue I was having (lines along the edges) resolved itself. I tested with the air-assist off but also made sure my focus lens was not loose on a subsequent test. All mirror-brackets (?) are solid and aren’t moving - neither are the 3 mirrors.

grub screws are the headless bolts which have allen wrench holes recessed into them and are used to hold the drive gears for the belts onto the stepper motor shafts and hold the idler gears(pulleys) on those rods.

You have to look really closely to make sure the belts are aligned on the pulley and not ever hitting the walls of the pulley gears. Same for the idlers because very time a belt tooth hits the edge of the gear/idler it changes the diameter and pulls the laser head more or less than it should. Same goes for if they put the wrong belts on the machine and the teeth of the belts are not perfectly fitting the drive gear slots for the belts.

And it’s good to see you are willing to google for things you hear and don’t know about. There’s lots of information out there on how this stuff works and doesn’t work.

And since this isn’t really a LightBurn issue, there’s a forum called Maker Forums which has lots of laser, cnc, 3D printer experts who can chime in with help.

Ah - so grub screws are set screws - those I’m familiar with. Your explanation is brilliant - thank you for that. I’ll take a look at the belts/gears now that I know what to look for.

Checking out Maker Forums. Thanks for that!

Se hai un controller KT332N fai un aggiornamento del firmware, risolve proprio questi tipi di problemi. Trovi il file sul sito OMT e esegui aggiornamento usando RdWorks.

Having searched for KT332N firmware on the usual OMT / Ruida sites and found nothing, a direct link to the site and file you recommend would be very helpful.

As a rule of thumb, never update firmware unless it has a description saying it will solve the specific problem in that machine.

One of my machines has a couple available firmware updates. No details other than date of release. I requested a change log from support. They said no such thing exists. I suggested they contact their engineering and/or software dev teams and assured them this info DOES exist. No response.

I never updated.