I am having an issue with a crackling noise where the wire to the power supply connects to the wire for the bulb.

Thinking there was an issue with the power supply itself, we replaced the PSU, but still having the same issue.

Wondering if this has happened to anyone else and wondering where to go from here.

We have an 8Ow Chinese laser.

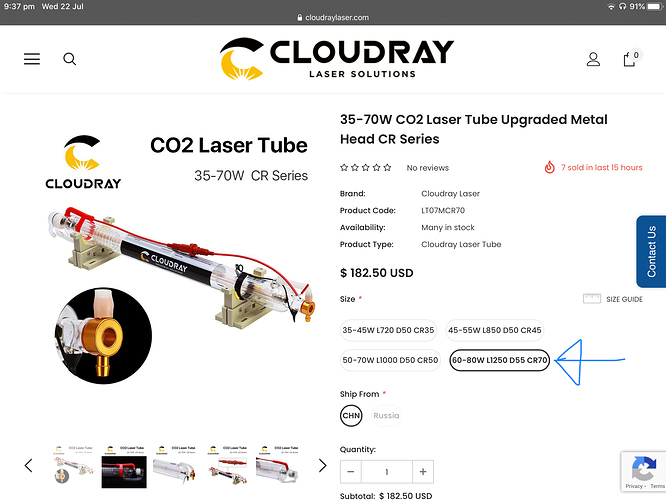

I just recently had this with a 60watt chinese. It was electrically arcing from that same point down to the stepper motor. It is not a good sign at all. Your tube is most likely dead. I removed my tube and found on the back where the electricity was leaking from as there was a big burn mark on the tube. Sorry but perhaps yours is gone too. I tried some extra silicone first to insulate but no luck. So ended up getting new tube and installed last week and all good now no arcing. By the way, the tube i got [cloudray 60-80 watt) is so much better quality and manufacture than the original chinese one, and much more powerful as getting double the cutting speed.

where the wire to the power supply connects to the wire for the bulb

You mean that big bulky connector which connects the two cables?

If so make sure to open it up (of course when laser is off) and check if there is still a solid connection. Signs for a not so solid connection are burn marks because of the arcing.

Will you send me a link for the tube that you purchased? This is the thought that we had but just wanted to make sure before we purchased! Thanks

No not at the white connector, but at the back of the machine where the wires connect beside the tube.

You have a poor electrical connection that is finding the shortest, least resistant, path is straight to the chassis.

Check the high tension lead to make sure it hasn’t abraded against the chassis and is earthing before it even gets to the tube.

If there’s any abrasion, slip a couple of 50-100mm pieces of heat-shrink over the cable and activate, one at a time (do one over the abrasion, then slip the second over the first and do it again. 20KV has a habit of slipping past the tiniest of holes.)

If the cable is fine, it’s likely your connection from HT cable to the tube.

The anode (power in) side needs a solid, clean connection. It’s only a few mA, but it’s at thousands of volts, which gives it the energy to jump to the nearest earth rather than travelling inside the tube to the cathode (earth side).

Slip a piece of heat shrink and a piece of silicon tubing over the connector while unplugged - 50mm for silicone and 75mm for heat shrink is plenty.

Clean the connector and the plug and fit the plug to the connector firmly - there should be no movement at all.

Spread some RTV silicone liberally on the join - bathroom sealant. Use the ‘neutral cure’ type, as the acetoxy one produces acetic acid which eats away at the connectors - and slide the piece of silicone tubing down over the join. Make sure the end of the tube is fully immersed in the silicone. Fill the other end of the silicone tube with silicone, as much as possible - make sure the end is fully immersed in silicone. Slide the heat shrink down as far as it will go, right over the connector, then wait for the RTV to cure. At least a couple of hours. Then activate the heatshrink.

You will have a solid, arc-free join.

As to whether your tube is dead or not, until you have fixed the connection, you won’t know. While you’re at it, make sure all over your chassis grounds through the centre pin of your power cable using a multimeter - there should be close to 0.000 ohms between all ground able components and the centre pin.

Unless you have a problem with your electrical wiring, don’t use the ‘ground pin’ on the chassis to earth your laser. Use it to earth your water reservoir, if you aren’t using a chiller. Always make sure all connected equipment are using the same ground - air assist, extractor, chiller/pump, laser, and if connecting by USB, computer.

Earth/ground loops cause more problems with lasers than just about any other source of problems.

I got the cr70 one and also their 80 watt power supply. I would highly recommend you get this too if it is compatible with your power supply, if in doubt send them an email, they are very responsive.

Just as an FYI, having a larger amperage/wattage PSU is no problem at all. It just doesn’t need to work as hard to deliver the correct mA.

Having an underpowered one can be OK, too, depending on your use. If you rarely venture up into the higher end (70%+) of your range, a 60W PSU on a 70-75W tube is fine.

If, however, like me you run more at 85% than anywhere else, having a lower-spec psi can cause issues.

Moar Power is always good

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.