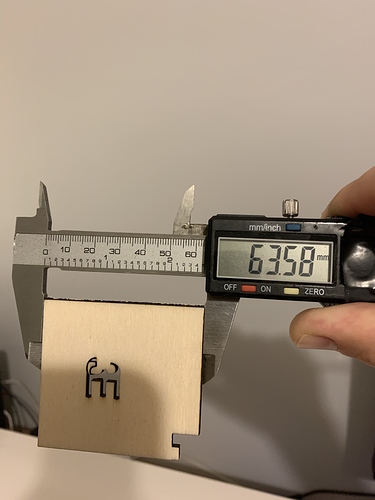

I did some test to check dimension of the cut. This plywood rectangle should have 64 mm, as you see mine is 63.58 mm Can I get more precision of cut ? Any setting or parameters should be checked ? I use diode laser and grbl controller .

I would suggest you take a look at the kerf offset settings.

the laser beam has a width called “kerf”. depending on laser/settings/material/… it can go from 0.1mm (best case) to much more. this is the width of the material that is burnt/destroyed.

you should always expect that your piece will be a bit shorter due to the kerf. you can counter this with the kerf offset in LB, so the path of the beam will be slightly on the outer.

most of the time, with 0.1 or 0.2mm kerf, it’s ok, and it allows for setting pieces in place.

if you think your cut dimension is still a bit off (not due to kerf), you can also look at the config of your motors (number of “steps” / cm), you can do this by burning the largest piece you can and compare the real size with the theoretical, then adjust the steps/cm accordingly.

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.