Hey all im brand new here.

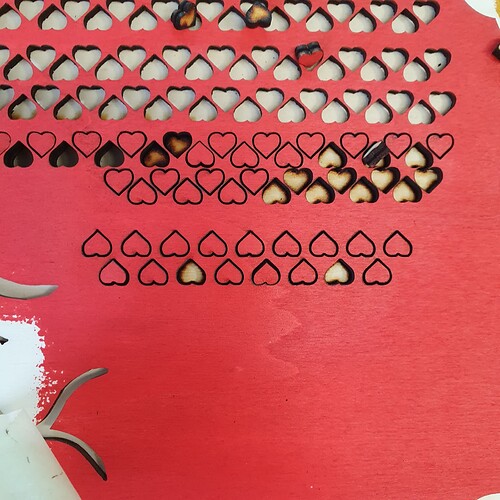

I have a project that has really small hearts in it approx 6x6 mm big.

When I cut them (8mm/s) speed they are not 100% ok shaped.

I think there must be some settings for the machine to slow down in corners?

Before I had a k40 with m2 board and it was perfect.

Any help highly appreciated!

looks to me like you are using far to much power and they are all burnt.

you have air on?

setting to change radius speed are in device settings in LB.

Some information is missing here. Your powersetting and material thickness / type and in your profile you have not mentioned your tubes power rating, is it 40 or 130Watt?

Are you saying that your K40 with M2 controller could run with LightBurn?

before this laser i HAD a k40 with m2 and k40whisperrer software…and all was good…

on this 1390 100w laser I’m having problems with really small things…

material is birch 3mm I’m cutting at 8mm/s at 17%

and yes I have tried all sorts of speeds and power… this currently is the best option I could tweek…

any ideas aprechiated

I have 100w 1200 x 900 bed laser also, I don’t have any 3mm Birch but have 4mm. If you send your file I will test it also for you.

For 4mm I use 75% power(max) 55%(min) @ 22.5mm/s cuts clean and fast enough.

Make sure you set a min power lower than the max, so the laser can control the power between them when it changes speed on curves/corners

With my 60Watt machine I run 30mm / s and 45% -11mA to cut nicely in 3mm plywood

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.