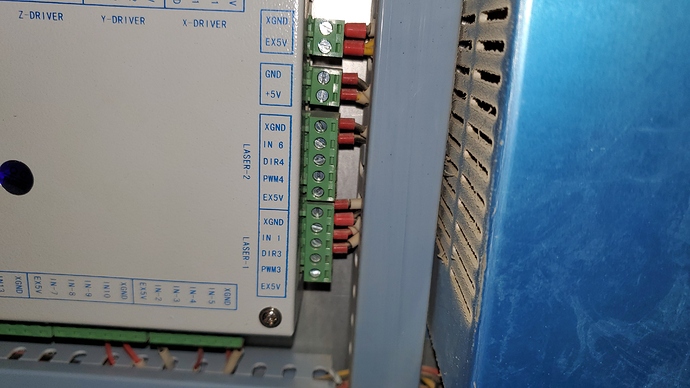

on the tl403, it has 2 power source inputs, one external and one internal…the swap looks straight forward except for this, the ruida has one input…all the drivers seem to use the external power looking at the diagrams…which wires do i use to connect the ruida…

The 6445G is 24V.

yeah…that is what i am figuring, glad i got the psu to go along with it

Yeah, I had the 410 so it used the same power, but the 403 is meant for smaller systems so it’s only a 5V box.

looks like redsail used a psu combo of 5v, 24v and 36v…the machine is a x700. Of course, that particular psu is not available anymore. Not sure if i am going to wire in just the ruida psu seperately or splice into the 24v line of the redsail psu…i hate splicing so probably just install the psu somewhere and capping the 5v lines

The other common difference is that Ruida defaults to ‘active-low’ signal for the laser firing, where the TopWisdom is ‘active-high’. The Ruida can be configured for either, and some power supplies have both inputs (L and H). If you see the laser firing at the wrong times once you’re up and running, this is likely why, and easily sorted out in the settings or the wiring - just ask if you get stuck.

Track down your drivers, some of them have different power options. After I went though my China Red, I discovered the only thing that was truly 5V was the red dot. Took care of that with a resistor so everything in the cabinet is 24V DC beyond the 110 to the two power supplies and the exhaust. I have the little diaphragm compressor I can plug in it needed, but the air compressor and cooling are relay controlled from separate power sources.

I recommend that you utilize separate power supplies for each component:

- Controller

- Motors / Drivers

- Laser

TheCO2 laser is on it’s own PSU and only controlled by the controller.

The controller is such a low power consumption that unless you have some really wimpy power supply, there is no reason to have it on a separate PSU from the motors and drivers.

I have everything in my machine that is 24V on the same PSU with no problems. Did a check when I first made the same swap. The only time it even gets close is when the steppers are racing across after a reset or job finish. Granted, if they sent the PSU for just the controller, it may not have the power that a full unit supply would have that shipped with the machine. Mine is 3.2A input, but 6A on the 24V output.

i may just do the separate psu for each to save me trouble down the line. It is a 220v system currently, and does run well now,so no big rush, just as it ages, i am finding parts for it are low in supply and autolaser, while i am verse in it and can do just about anything, the ruida may be more user friendly for my wife

Yeah, you do need to keep an eye on your power draw. I’m US, so everything I have is 110.

i’m in the US as well, Washington State

Like I said:

Just a few reasons: troubleshooting easier, power management easier, and interchangeability of components easier.

Sounds like you made the right decision going forward.

Consider, for example, my Ruida is 24v DC, X / Y Yako Drivers and Motors 46V DC, Z Yako Driver and Stepper 60v AC, and of course the LPSU.

@Dave01, if his machine is supplied with 240v, power draw doesn’t change. P = I * V. Same power / effectively half the amperage.

also…

You’re on 120V split phase (180° out of phase) BTW, not 110. And more than likely, it is probably closer to 123V on your main breaker.

Phase 1 120v + Phase 2 120v being 180° out of phase with each other (sine being exactly inverse) is what creates 240v in the US. Or, in a 3 phase system, when each phase is 120° out, you get 208v (but the advantage being less on / off gaps in the supply of electricity to industrial equipment).

Ah, with 220 I thought you were overseas somewhere. Every machine is different. Every manufacturer tries to shave a few cents in his cost in a different place. I guess I’m lucky I have 6A available for my 24V output. I did add a number of switches to be able to turn things on and off besides the main and E-stop.

Jeff, In a perfect work in a major metropolitan area, I would probably have 120 + / -. In a rural area on an electric cooperative, I float between 110 and 114. I get more stable control from my whole house generator than I do off the pole. Should I have 120? Yeah, but everything in the machine is LABELED as 110, and I have had no problems beyond a few melted main and E-stops switches they forgot to swap out when they made the change from 220 to 110. 7A switches tend to get a little… soft, when you are pumping 7 - 8A on a consistent basis through them. They sent 12A as replacements.

Thank god I’m not in LA with the rolling brown outs and black outs.