I recently looked at the current requirements of the M50 and it was just below 3A for normal usage and higher than 3A at peak usage. If you add the requirements of the controller and steppers you’re looking at 5A to be safe.

So assuming you have a 5A power supply and the controller can handle that much current then you may not need a separate supply but this will depend on your setup. I’m not familiar with what the controller in the A5 can handle.

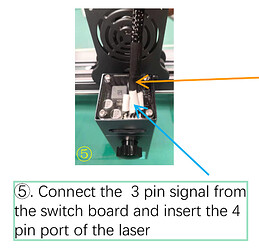

This is a little bizarre but they have you plug from 3 pin signal on the interface board to the 4 pin on the laser so it looks like it’s not even being used. If your controller can handle the power draw then seems you could use the same cable to connect directly.