I’m thinking I have to replace my laser tube after 8 months of owning my Orion Motor 80 watt laser with ruida control board. The laser is cutting out. Visually the laser is firing but if I put a post it note in front of the laser when I pulse it, it works a quarter of the time. It started having issues after a month of sitting with no use it started fading out when running a job, I thought it was alignment issue but re-aligned the laser and it got worse. My laser tube was making a crackling noise recently but it was intermittent and when I checked I couldn’t find anything wrong. When I first installed the laser I used wiring nuts and overheated them, I had to solder and heat shrink the tube in after almost lighting my machine on fire. I currently use a Chinese pond water pump and I am looking at upgrading to a cw 3000 or cw 5000 because I’m looking at investing in a 80 watt laser tube with 18 month warranty that cost $700. Any advice on replacing the laser tube and if a cw 3000 or cw 5000 is better.

I use a CW5000 on my 80/100W tube. I believe the 5000 has active cooling, I think the 3000 is passive.

Are you sure it’s not the laser power supply.

I’m pretty sure it is not the laser power supply because when I pulse the laser I visually see the laser in the laser tube.

How long did you pulse? And you mention pulsing, only works a quarter of the time.

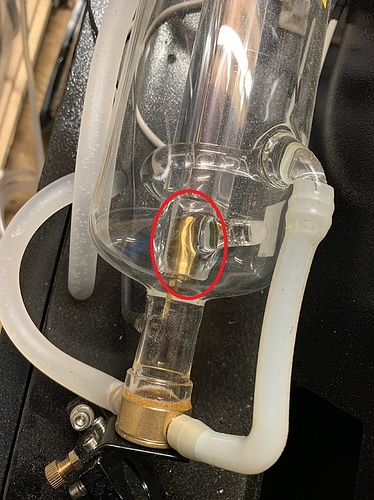

Do you see a gold tint on metal cylinder that’s inside the tube where the beam exits?

It very well be the tube, but nothing you have mentioned rules out the power supply.

OK, I can’t say that every laser tube is the same, but for mine, that metal part is chrome, polished stainless… Your tube looks like an MCW which also is not tinted like that. The gold color is a sign of having been run at too much power. So maybe your tube is cooked.

I have a RECI W2 which I am very happy with. GSI is also very good along with EFR.

When you get a new one, make sure you stay within it’s power limits. I have heard OK things about Orion, but many places put in small tubes and over drive them.

If you do not have a milliampmeter in your laser you need to install one. It will show you many things that you can not see without one. Also what is you water temp? You need to ensure you are not operating out the tubes specs.

Tube current and temp are key to long life.

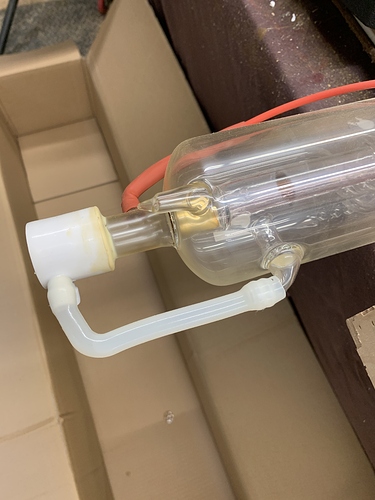

I see you have a lot of air bubbles in your laser, it’s not good, they gather in the wrong place then your laser is done.

Thanks for all the advices. I ordered a new tube and a cw3000 cooling system to replace the pond pump that came with the laser. Hopefully that fixes the bubble issues and are you talking about putting a milliampmeter in line on the laser?

You should order the CW 5000! The CW 3000 is the same thing as a pond pump it has NO cooling except the room air a ( little ) better than a pond pump. If the room gets hot it will HEAT the water. The CW 5000 has a little A.C. in it.

I second the comment from @olddogTim. The CW-3000 is not a proper chiller. It is a fan blowing on a radiator which could be adequate in a colder climate with air temp <= 20C and only needing to drop the water temp to ambient temp. If you are in an area with hot summers you want a CW-5000 (or CW-5200), which contains a compressor & refrigerant to cool the water temp down to 20C (or whatever your tube requires).

There are DIY cooling options like re-purposing a small fridge/cooler with ice packs - you’ll find some examples on YouTube/Reddit - but you’ll need to motior the temp pretty closely to ensure your tube lasts for the rated time.

I also think it is a bit unfortunate with your choice of the cooling machine. It is more expensive to buy a CW5000 but it is in turn a cooling machine, a CW3000 is actually only a pump, one that is larger than an aquarium pump but still only a pump with a fan. However, an active cooling machine does not solve your air bubble problem alone, you should always keep an eye on this. Additives to your demineralized water will also help get rid of some of the very tiny bubbles.

An ammeter (in milliampere range) is essential to be able to operate a laser machine, dioelaser or CO2. I mean a laser machine without an ammeter should not be sold.

Without it, you do not have an earthly chance to adjust your power to your (standard) laser and end up, running above its specifications. You also do not have the option to repeat the same cut at a later time without an ammeter, because the machine’s potentiometer for the power setting is “independent” of the laser tube’s conversion of the supplied energy (from 0 to 100%) and the tube itself changes over time.

Definite yes to the above comments. Running my RECI easy ( no over driving ), my CW5000 does kick in and chill the water during long jobs. Depending on the jobs you do, the CW3000 will eventually fall behind. I know in the case of my RECI, the warranty was dependent on having a proper chiller ( had to be active and of a certain capacity).

I just looked at various pictures of the Orion 80W lasers and it does not look like they included a mA meter. You really need to add one to make sure you are not over cooking your new tube.

Thanks again for the input I was able to return the cw3000 and have upgraded to a cw5200. And my laser definitely doesn’t have a meter so I will look into adding one I have time because the tube is going to take a while to come in.

When firing the tube you have, what color is the plasma? If it’s purple, the tube is probably ok, but if the plasma glows white, it’s dead.

The picture posted looks like the laser is firing. The cathode shows signs of over driving the tube.

What is the best way to install a meter on to the laser tube?

I am afraid the cw3000 will not do the job. I owned one with a 50W lasertube and temperature was not stable.

Now i have a CW5200 that cools the tube to 17 degrees Celsius while room temperature is 28 and more in summer (I have everything on the attic)

The meter goes in series with the ground lead of the laser tube. Hardest part on the installation is deciding where you want to put it.

There are analog and digital meters. Most of the digital ones I have seen have poor displays, hard to see at any but one very narrow angle range. If you get one of the analog ones, look for 0 - 30mA.

I’m not sure where you are, but http://www.lightobject.com is a good source for parts.

I also did a quick google of laser ammeter and several articles come up to help with the actual install wiring.

Once you have it, figure out what power setting gives you the max current for your tube and set that as the max in the controller. There are usually more than one max, one is for the maximum rated output power ( not peak, but what you can really run it at ), and one for max life ( will be the rated max power of the tube, 80W ). For example, my RECI 80W I set the max to 25mA to get max life. It peaks at 100W at 29mA, and has a max running current of 27mA.

One of these days I might get a power meter and see what I actually getting, but the test report with the tube said 80W @ 24mA.

That was a long was of saying, once you have the meter installed, know what current your tube can safely run at and set it.