HI Guys

i am very new to this laser stuff so don’t be to hard on me.

I have new a red & black 80 watt china laser. When powered on it goes to top right corner then in 2-3 seeconds it goes to left bottom. On the panel the right, left. top, bottom arrows move laser head in the right directions. But in LB the move arrows are backwards. i did a rest on panel and probably should not have done that. If i make a square and put it on left side and push start it goes over to right side.Can someone help me. And i know i will have a bunch more questions.

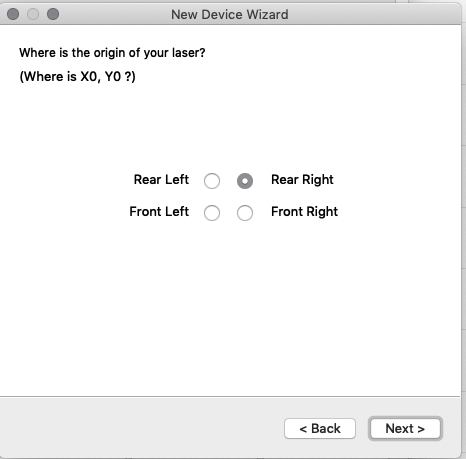

Your RuiDa should home to top/right.

You need to make sure your LB is set to the same:

Thanks Bonjour , that worked.

Can you tell me what size breaker to have this laser on.

Normal 15A home circuits are more than plenty for an 80w.

An 80w laser by itself won’t pull more than about 600w. (my 100w at 80% power pulled 628 watts total) If you have an exhaust fan, chiller, or air compressor, those will add to the overall amount. If you plan to do photo engraving you should put those on their own distinct circuit, as a chiller or compressor powering up will often cause subtle dips in the laser power output.

We run 220v here and all my stuff is on the same 10A circuit from the distribution box, using 2.5mm cable.

I’ve put some hefty machines in domestic situations using regular 10A outlets and not had them trip.

My exhaust and air-assist are off the back of the laser itself, using the 20A relays built in, but the supplier I get my machines from does a proper job of wiring and has real UL and CE mark compliance. And they are both on before cutting commences, anyway. Stuff bought off eBay, you take your chances. Personally, I would get all electrical connections checked - or do it yourself if you’re handy.

It’s more important to ensure you have good earth, through the machine and through your supply. Don’t use the earth post on the back of the machine - the centre pin on your power lead is more than adequate, assuming it is connected properly. You can use the earth post for supplemental earthing - like keeping your water reservoir at the same potential as the machine, if you’re not using a commercial chiller.

But keep in mind that 240v @ 10 amp is 2,400 watts while 120v at 20 amps is 2,400 watts (and that a breaker will trip usually at about 90 to 95% rated load).

My breakers are 15A, with RCD’s

Thanks Oz

I think I need to check and make sure wires and breakers are efficient.

Thanks Bonjour, you guys answer back quickly.

Thank you Stroonzo.

You guys are great and going to get tired of seeing me post questions.

I don’t know very much on this but I’m learning.

Thanks again

Hey guys i’m back.

On this china red & black 80 watt, what thickness of lexan is it capable of cutting?

cutting is a function of time/power. Want to cut thicker, slow it down and increase power.

Nobody can tell you what your machine can do - you need to experiment.

I have a machine with a 130W tube running at 100W and I cut 10mm acrylic reasonably easily at slow speed - 10mm/sec

One thing to take into account is the focal length of your laser - a ‘standard’ 2"/50.8mm lens is poor at cutting anything over 5mm - you get a notable V shape to your cut, due to the angle formed at the focus.

If you are looking to regularly cut thicker material, get a 76.2mm or 101.6mm lens.

Do you mean lenght of laser head tube?

No, the focal length of the lens - which will dictate the tube.

You can buy add-on spacers to extend the length of your tube.

Ok, i got it now.

Thanks Bo

Quick reply

So mine is standard lenght that comes on machine. If i want to cut upto 1/4 inch plexi, i would put a longer tube in it. Don’t bash me to hard, i am learning this stuff.

the 50.6mm lens cuts 6mm acrylic, but it’s not great.

A longer lens cuts thicker material better.

The lens tube length is immaterial, except that you want to get the air assist as close to the workpiece as you can. You can just drop a longer lens in and it will work just fine, but you won’t get the air pressure at the workpiece that you would with a correctly-sized lens tube.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.