I need a validation or rejection of my theory that this machine has a twist in Y, non-parallel rails.

Trying to sort out a 900x600 80w rdc6445 machine. Spent 2 full days trying to align and shim it with no success. I’ve done quite a few of lasers, but this one throws me for a loop.

Location index looking from the front of the machine, beam comes in from top left:

1 - top left

2 - bottom left

3 - bottom right

4 - top right

The person who got this machine explained to me that doing usual alignment he’s getting beam travel between location 3 and 4, while 1-2 and 2-3 are perfectly centered and spot on. For me its a clear sign of twist in Y, non-parallel rails.

So i went to see myself. I, foolishly, assumed tube set from factory would be more or less ok (on that later).

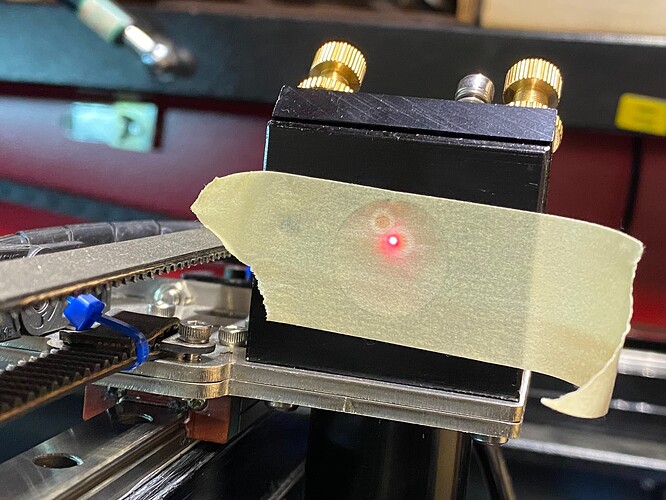

Upon trying to align it I, as well, would get perfect alignment in 1-2-3 locations, but 4 would always strike high, by quite a lot (~5-6mm). And no matter mirror twisting i couldn’t get it out.

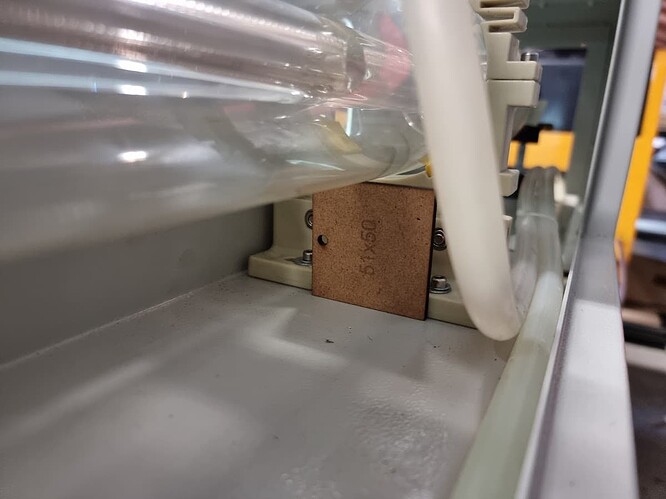

So i resorted to shimming. Tried all 4 rail mount locations, but the only location that made any difference was top of the left rail (position 1). So i started shimming it up by sticking ~1mm thick shims under the mount foot. By sticking 4 shims i reduced travel between pos3-4 by half (to about 3mm). At this point the work day was at an end, so i made machine workable, tightened down and left it as is.

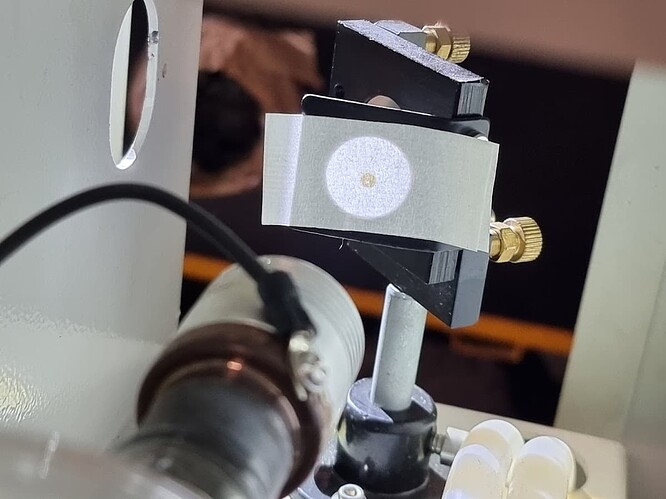

Second try involved me completely rechecking all beam components (bar mirror1). What i discovered was that tube mounts were wayyyyy off parallel to the machine in both vertical and horizontal positions, by significant margin. So i re-spaced tube to strike center of mirror 1 and tried realigning again (after removing all the shimming, to put machine the way it came from factory). Exactly the same thing happened - pos1-2-3 perfect, 3-4 walk away by ~5-6mm. So i shimmed it again to make the machine somewhat workable again (walk of ~2mm), as it was close time…again… The only thing i never moved was mirror1, its still as it was set in the factory.

By my estimation i would need to shim 8mm (total, ±), but i cant do that for tube mounts don’t go high enough and i can’t adjust mirror2 and 3-head vertically. So now i’m just scratching my head and trying to figure out what next steps i should take.

Machine is sitting on concrete floor, feet had been leveled.

All of this is pointing at machine being twisted, or rails not parallel. I need someone else to either confirm or deny my thinking. With constructive criticism, preferably…

HELP

Some pics:

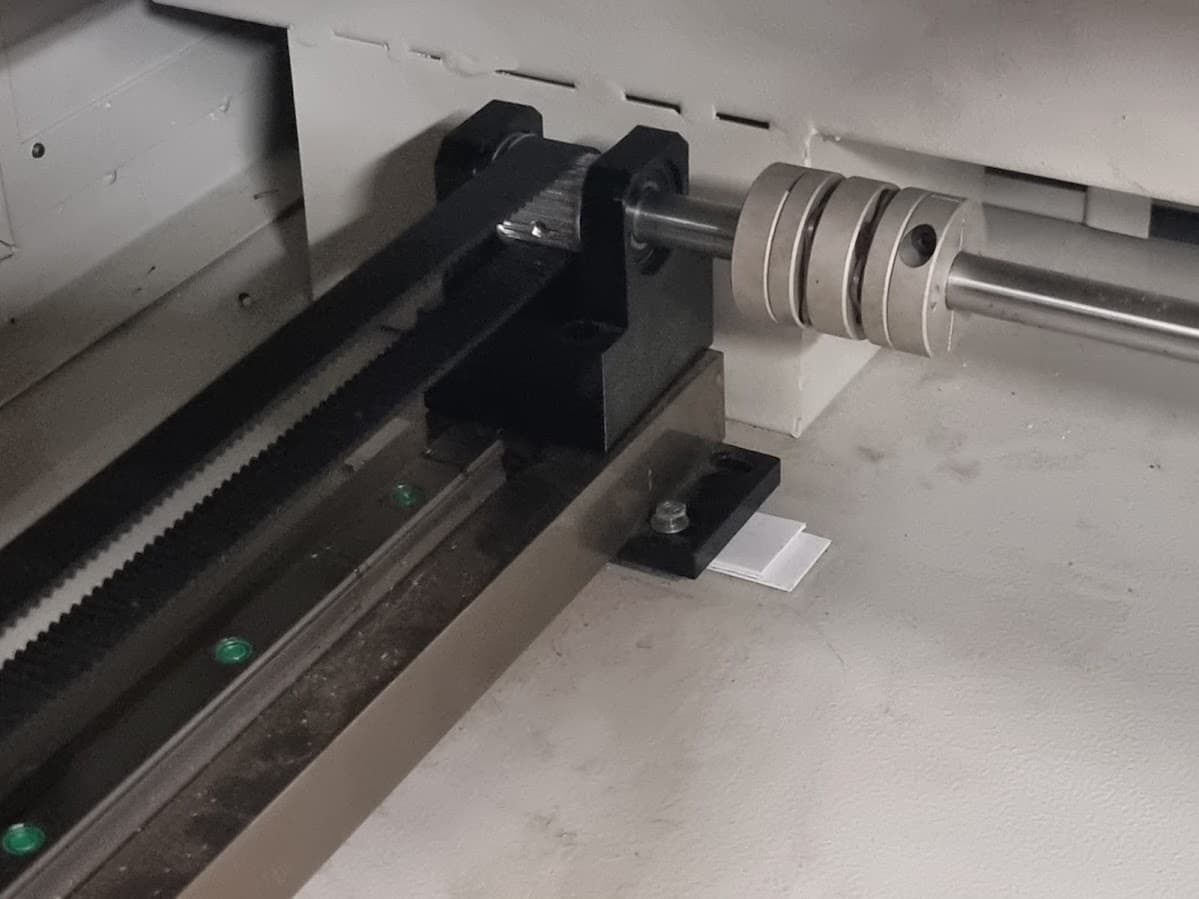

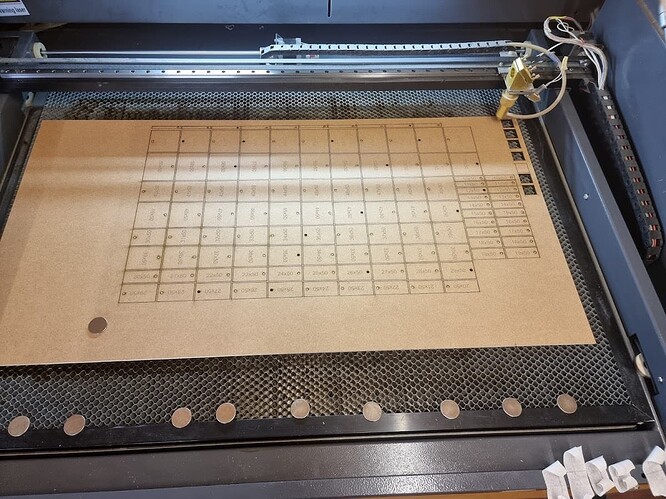

As the machine sits now, with 4 shims in…

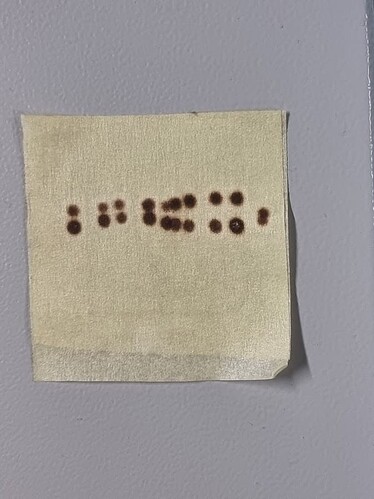

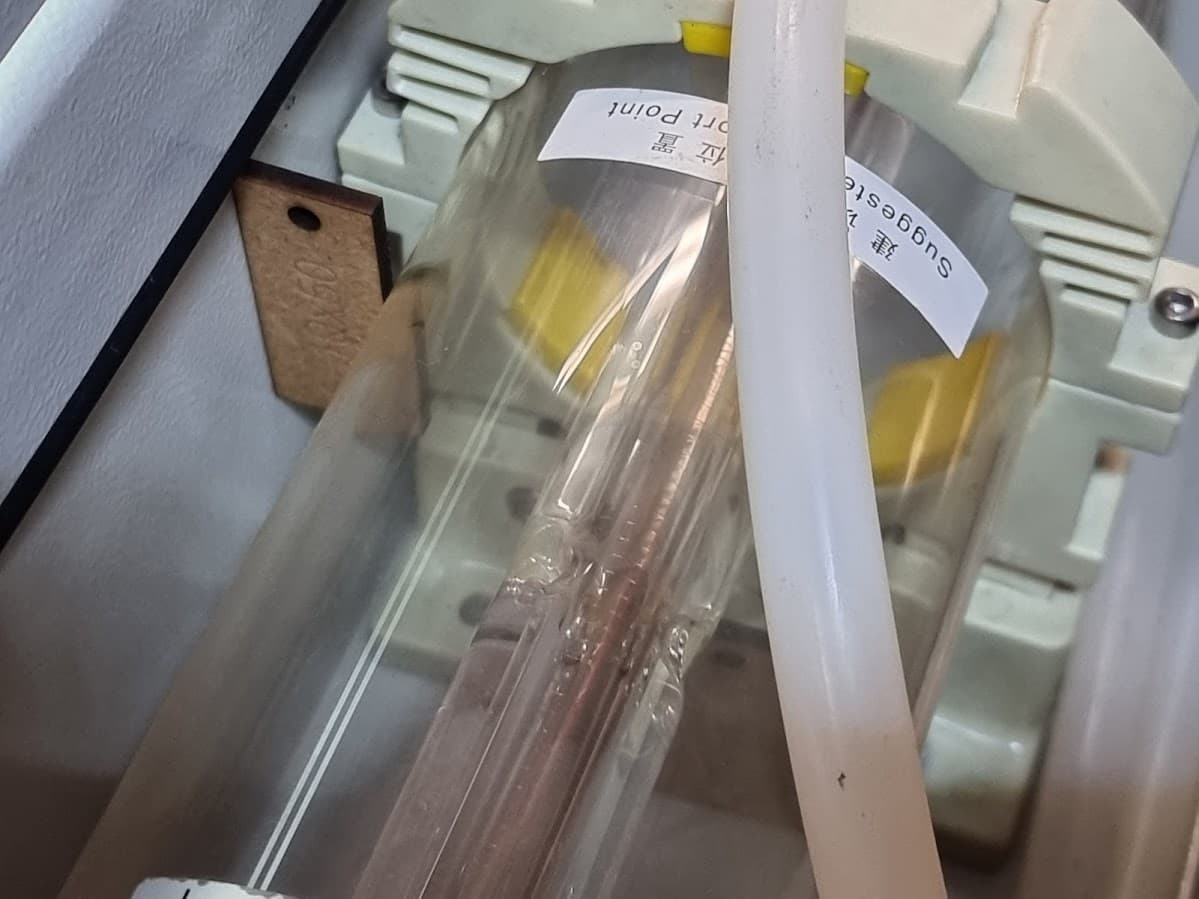

The gradual shimming test result, gap gets smaller more shims i add, all the shot columns are of pos3-4, then tape moved over, shimmed up and next test. (Tests were done with realigned tube)…

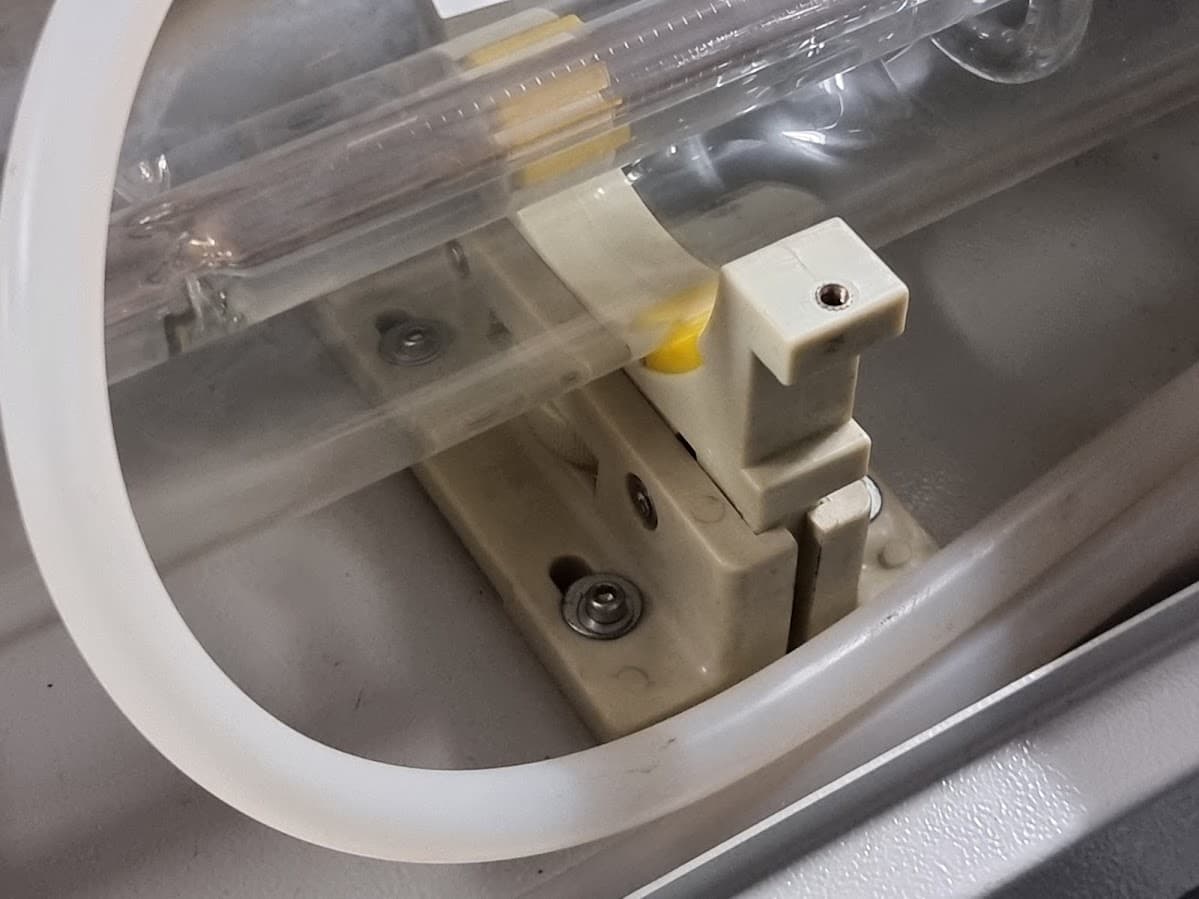

Next pictures illustrate how badly tube mounts were set. Note screws in the foot and gap between base and vertical adjustment difference. Effectively tube was sitting looking up and towards mirror1 (looking from back of the machine). I have now leveled and spaced the tube properly.