scratch that, i pulled the honeycomb, kept the slats in

Good point… I did pull the honeycomb and slats. I couldn’t get a repeatable method to center my rotary tool so I ended up taking measurements, and making a jig. Also, there would be some Tumblers that I would not be able to even fit under the laser without it hitting the bottom of the tip.

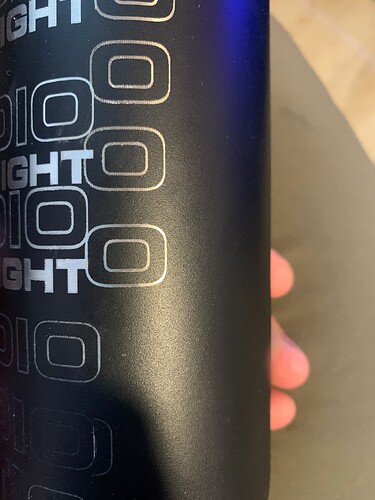

I just increased the DPI… earlier I was told that 300 is ideal and anything higher than that probably wouldn’t make a difference. This is at 600 DPI and looks the cleanest thus far.

also worth noting, I use the machines for wood. The rotary tool only comes out when I make some glasses as a gift.

do you know what the grippy coating on a stainless yeti is made from? you are basically burning it off and sometimes that’s bad news. i am curious myself because i might customize a few.

can’t tell by the photo what is the new stuff. did the skewing go away? that was the part that seems the most problematic to me.

To be honest, I do not know what it is made from. I just assumed it was paint, but definitely not something I would want to inhale often. Skewing went away, the glooming issue for me was actually the line gaps that the laser would miss. There still is a very small amount of that now, but I am play around with the line step speed. if that does not fix it, I might adjust y axis acceleration. I did a burn with the offset settings off and I really could not tell a difference.

i think they are saying 600 should produce overlapping passes, which can be beneficial on certain materials. you may be able to speed things up less DPI and more power?

have you tried a few lines (not shapes) to test what power and speed you need to get through the paint?

what happens to the extra power when it hits the stainless? it just bounces off random directions?

I see what you are saying. That makes alot of sense about the higher DPI producing more overlapping passes. I will try that too.

I have not tried to see how much power and speed is needed to get through the paint. I just started by trial and error as well as asked a facebook group I am a part of.

If you burn the stainless at too high of a power, it can produce darker shades… similar to wood. Those are the only observations I have made, but nothing as detailed as what you are asking. Hard to say what the results would be based on how the beam behaves after hitting the stainless part for too long.

darker shades had me thinking there is some kind of clear nano style coating over the metal of the entire cup that you are burning through thats under the paint?

Nope, not able to burn through that. After I get through the paint, its done. By the way, trying the less DPI and more power now.

I would love to know what you end up using for settings…i think it’s powder coating.

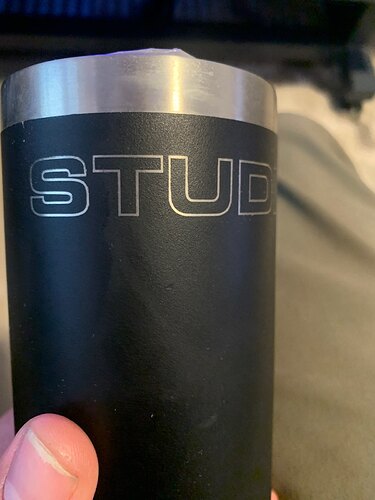

Okay so this was a game changer for me… Dropped the speed down (rather go that route to keep the life of the laser as long as possible), dropped DPI just slightly… 500 DPI here. By far, this is the best engrave yet.

Speed 115 mm/s, power at 30%.

If you end up engraving some yeti’s, an issue you might run into is the burn marks afterwards. Two good methods, this product is amazing… Blu Powder Coating Residue Cleaner by Enduramark

You can also go to the dollar tree and buy LA Awesome, pair that with a mr. clean magic eraser and it will work just as well.

I found this useful too when engraving or cutting new materials.

Last thing, I can’t stand waste. Whenever I burn on a yeti or Rtic, I require the customer to order one more (or i put it in the quote) because I have to have a sample to test on. After I burn a bunch of tests into it, I do not want to throw it away. Here is a way to put those to good use later.

I personally have not tried this yet, but plan to do so this week.

Looks great. Thank you.

I’m still curious what the coating is, but good to know the settings!

Thanks again for your help. Man after a week straight of frustrations I about had it with this laser.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.