First let me apologize if this topic has been fully covered elsewhere. I’ve searched through the forums here, on Snapmaker’s site, and general Google searches and I can’t seem to find this exact issue with this configuration. If it’s answered elsewhere, pointing me in the right direction would be much appreciated.

All right, with that out of the way, here’s what I’ve got. I’m running the latest version of LB (1.0.06 as of this post) on Windows 10. My laser is a Snapmaker 2.0 A350, recently upgraded from the 1600mW to the 10W (though this problem has been persistent on both units). I’m running the latest firmware there as well (1.14.2).

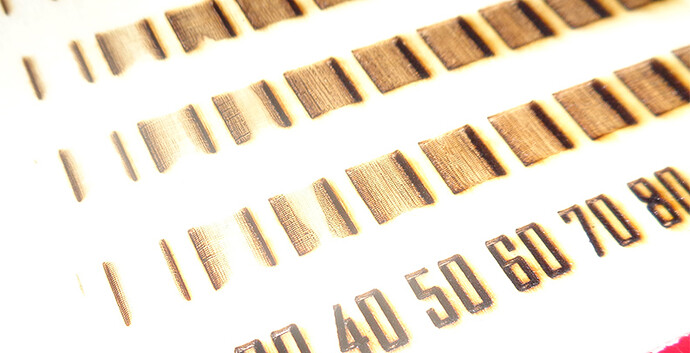

Here’s what I’m getting when I try to engrave using fill mode and LB-generated vector shapes (rectangles and circles shown here, though the problem manifests with text also):

(Please ignore the “1000” that completely burned through the plastic; that was my first attempt at using this material with this new higher-power laser. Live and learn…  )

)

Note that in the second picture, the larger circles only exhibit the more excessive burns to the left and the right, while the smaller ones exhibit the edge burning all the way around. This is because I turned on Crosshatching for the smaller circles. For all the circles, my settings were 0.050mm line intervals, 6000mm/min, and 10% power (1W).

The large circle at the bottom is using the default overscan setting of 2.5%, the top left circle is using 7.5% overscan, and the top right circle is using zero overscan. (The wood engraving is using 2.5% across the board.)

In addition to changing overscan settings, I’ve tried enabling and disabling the Fast Whitespace Scan option, which doesn’t seem to have an effect.

I spent a while trying to connect my Snapmaker to my laser and adjust the $32 setting (as described in the post “Still getting dark edges when overscanning”), before realizing that I’m not dealing with GRBL firmware, but rather Snapmaker’s own firmware, based on Marlin… once again, live and learn.  (By the way, I did set up the machine manually in Lightburn using the Snapmaker preset, not GRBL or Marlin.)

(By the way, I did set up the machine manually in Lightburn using the Snapmaker preset, not GRBL or Marlin.)

So that’s where I’m sitting; so far no matter what I’ve done, I get this persistent issue with the edges darkening perpendicular to the direction of laser travel. I should note also that this problem did not manifest while I was using Luban to generate laser jobs. But… well… how do I put this politely… I don’t much care for Luban.  Lightburn is a massive improvement to Luban except for this one annoying problem.

Lightburn is a massive improvement to Luban except for this one annoying problem.

I did manage to get a successful USB connection to my Snapmaker and was able to use the console and basic controls, send jobs to the laser, etc. (They really hide that mini USB port way too well.)

Anyway, knowing my luck, it’ll be some setting that’s been staring me in the face this whole time, but I feel like I’ve reached the end of my own troubleshooting ability on this problem. Any suggestions or advice would be very much appreciated.

Thanks!

Dan